Garment preparation method

A garment, workstation technology, applied in mechanical cleaning, textile and papermaking, high-pressure cleaning, etc., can solve the problems of low work efficiency, high labor intensity and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

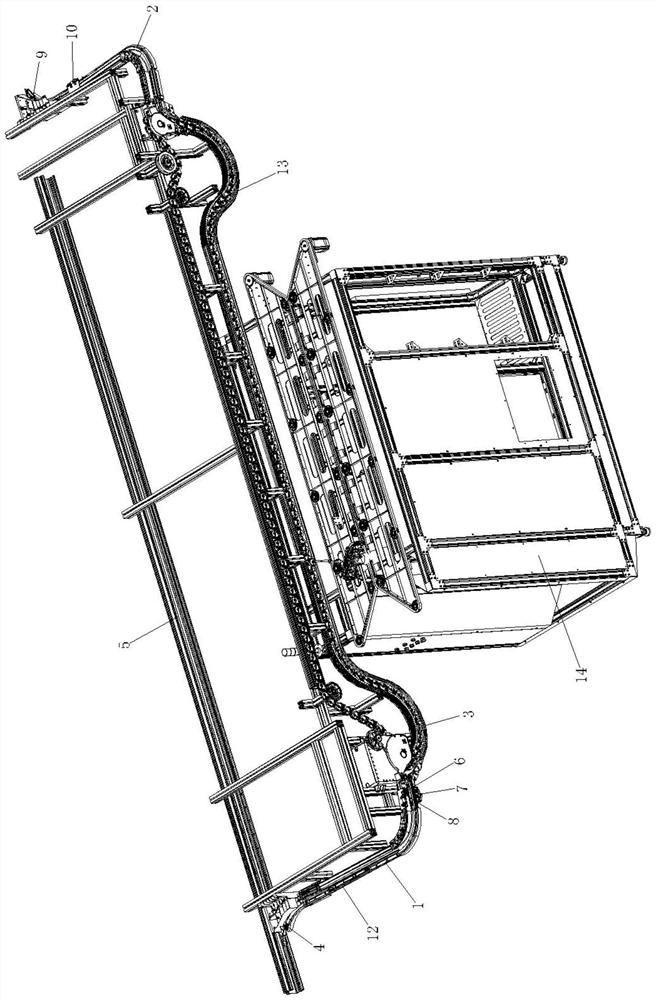

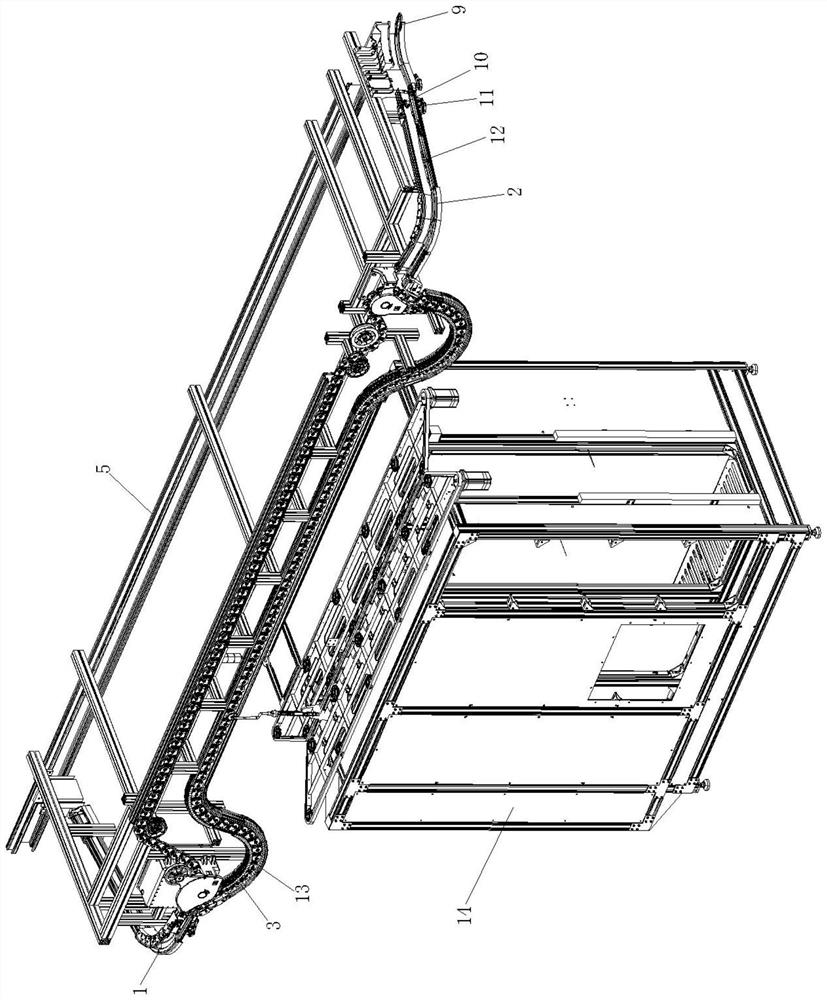

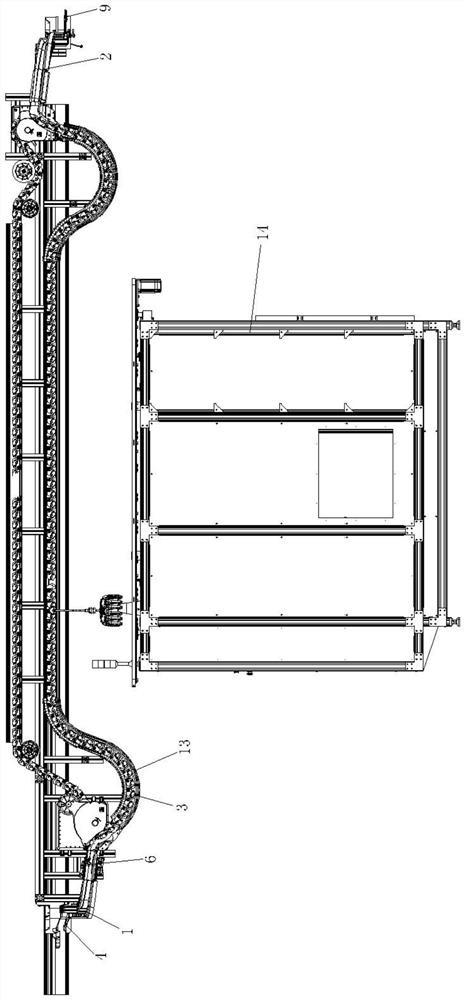

[0029] The following description and the accompanying drawings in conjunction with embodiments of the present invention will be further described.

[0030] Cleaning station of the present invention may be provided at a position downstream of all sewing station for sewing garments after complete clean up, cleaning station may be provided between the hanging system of the sewing station, sewing of garments during clean up, clean up and then the next step will be sent to a sewing process. In this embodiment, the sewing station and cleaning station is provided with a hanging conveyor line. In other embodiments, the suspension system can be connected by a plurality of conveyor lines formed by a bridging mechanism, the sewing station, cleaning station may be provided separately in the respective conveying line, for example, the conveyor line is provided for all the sewing seams of step workstation system, the conveyor line is provided for cleaning the cleaning process are all workstatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com