Method for operating spinning machine or winding machine and spinning machine or winding machine

A technology of spinning machine and winding machine, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, and can solve problems such as fluctuation of bobbin support pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

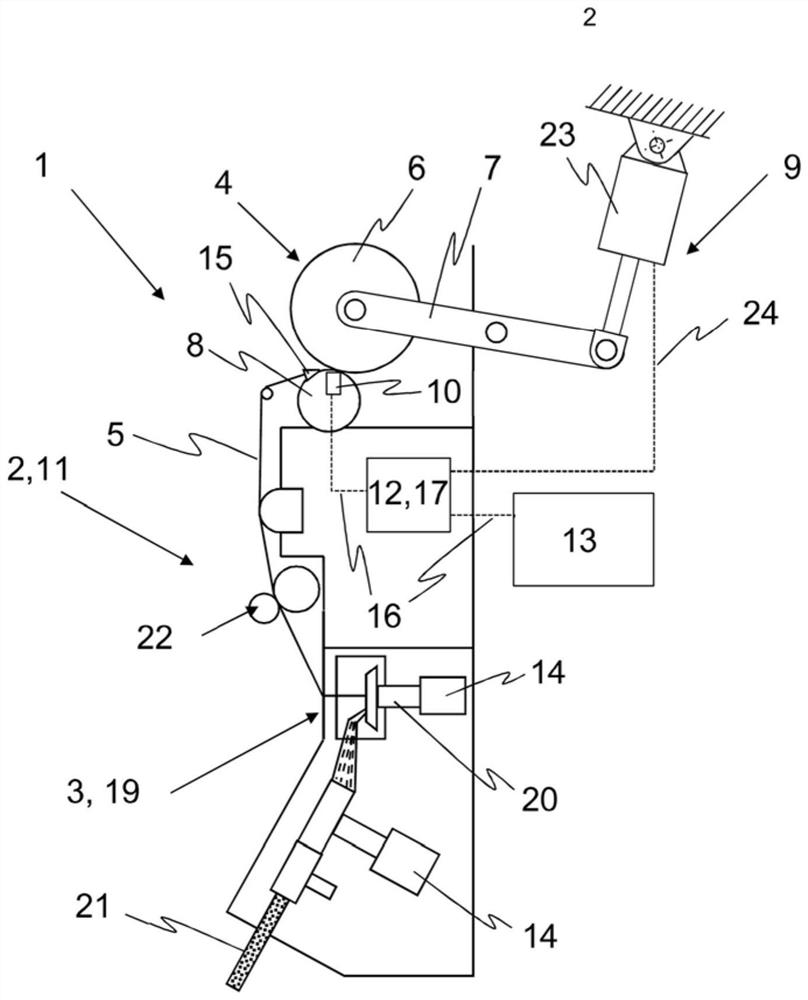

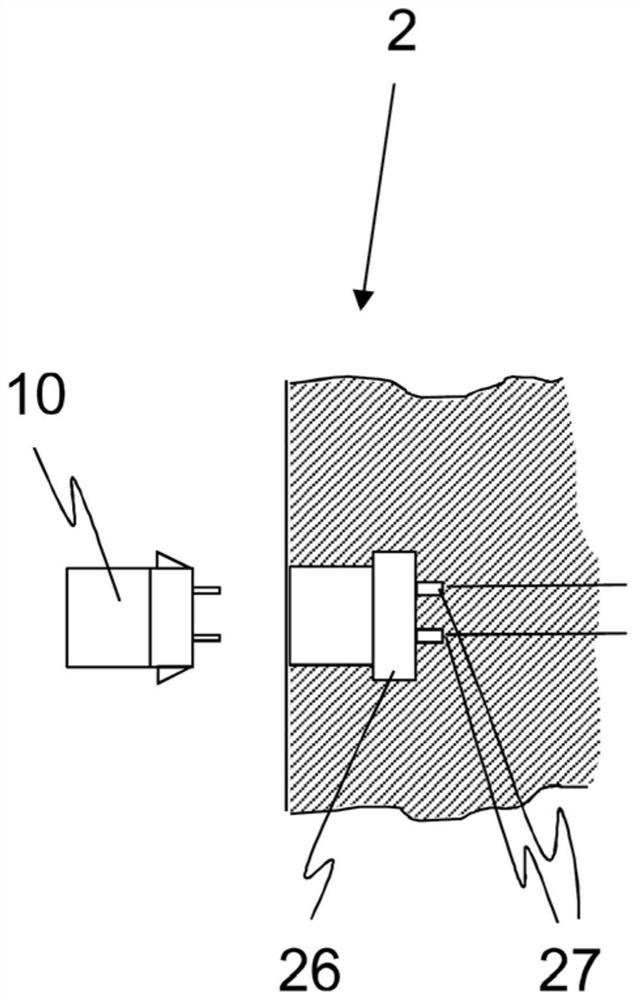

[0032] In the following description of the exemplary embodiments, features that are identical or at least similar in design and / or mode of operation are provided with the same reference symbols. Furthermore, these features are only elaborated in their first description, and only the differences from the preceding exemplary embodiments are mentioned in the following exemplary embodiments. Furthermore, only one or a few of a number of different components or features are often identified for clarity.

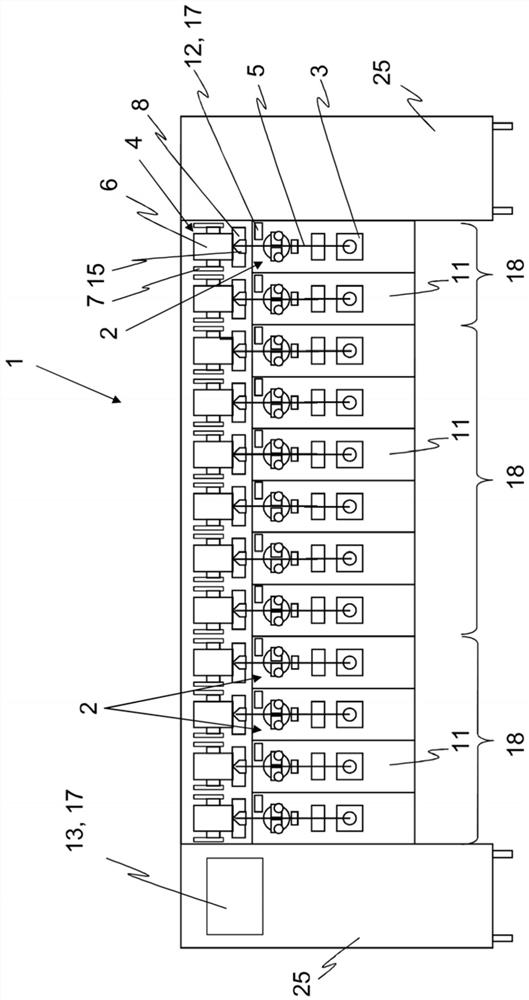

[0033] figure 1 A front view of a schematic overview of the spinning or winding machine 1 is shown. The spinning or winding machine 1 is known to have a plurality of work stations 2 arranged next to each other. Here, only the longitudinal side of the spinning or winding machine 1 is visible. The workstations 2 can only be arranged on one longitudinal side of the spinning or winding machine 1, but it is also possible to arrange several workstations 2 side by side on opposite lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com