Graphene conductive film spraying process

A technology of conductive film and graphene, which is applied in spray booths, spraying devices, etc., can solve problems such as inconvenient fans, and achieve the effects of convenient use, improved production efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

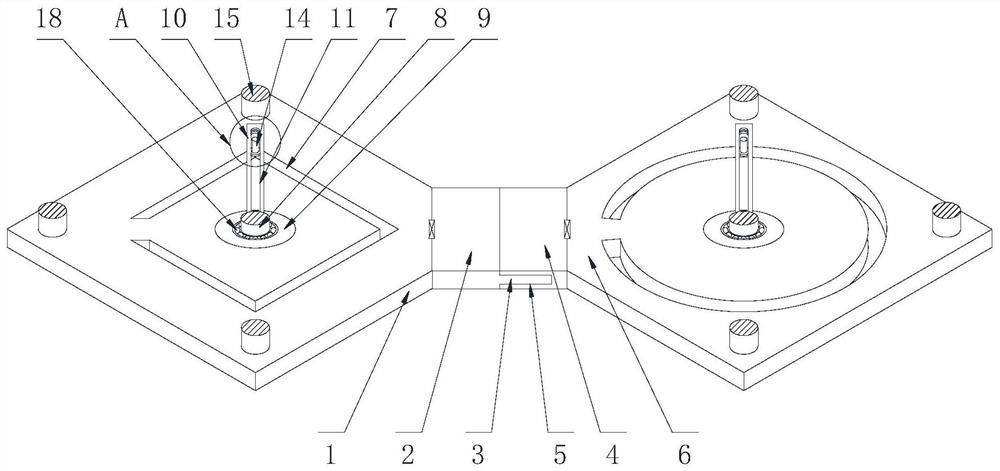

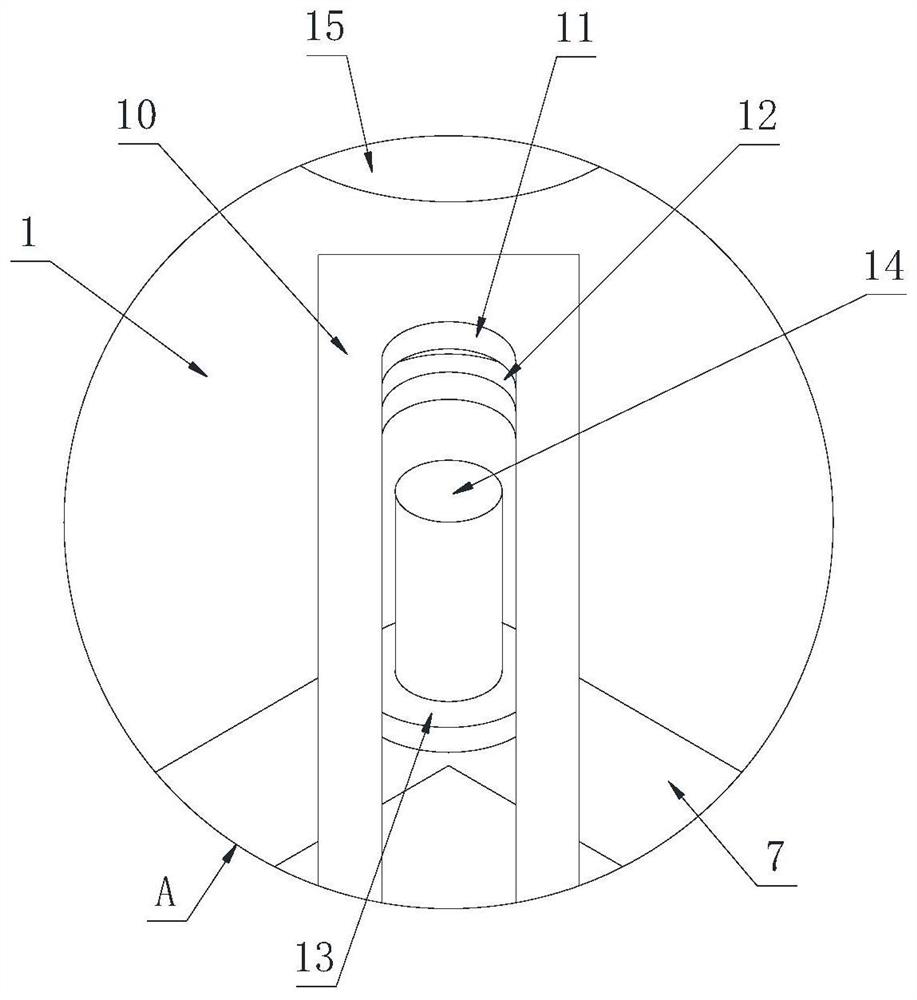

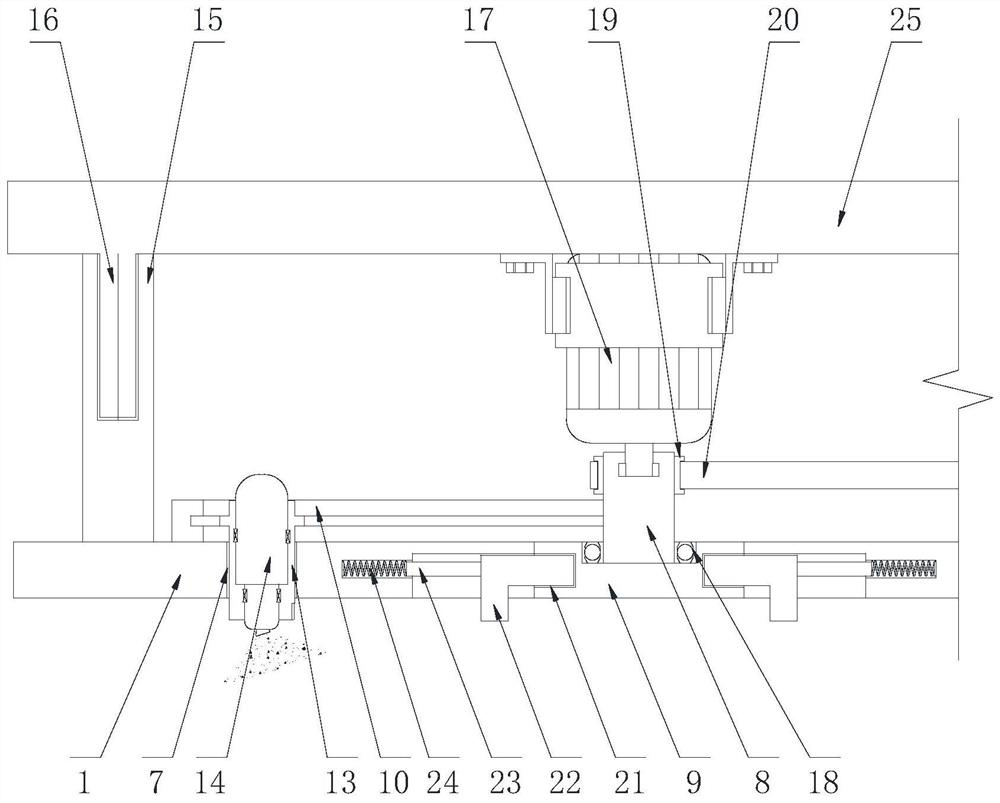

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0038] At present, graphene materials are widely used. Graphene films supported by graphene are widely used in the fields of batteries, photovoltaic power generation and electronic equipment. In the production process of graphene films, spraying equipment is required to spray graphene films. work, some existing spraying devices also have some defects in use:

[0039]When spraying, it is inconvenient to dry while spraying, resulting in low subsequent processing and production efficiency, and the existing spraying device cannot adjust the spraying path during use, usually the whole surface is sprayed, which is practical It is poor, and it is not convenient to detect the degree of combing of the sprayed coating after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com