Equipment load adjusting method and device, equipment, storage medium and product

A technology of equipment load and adjustment method, which is applied in the fields of equipment, storage media, products, devices, and equipment load adjustment methods, can solve problems such as unreasonable equipment load settings, and achieve a reasonable equipment load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

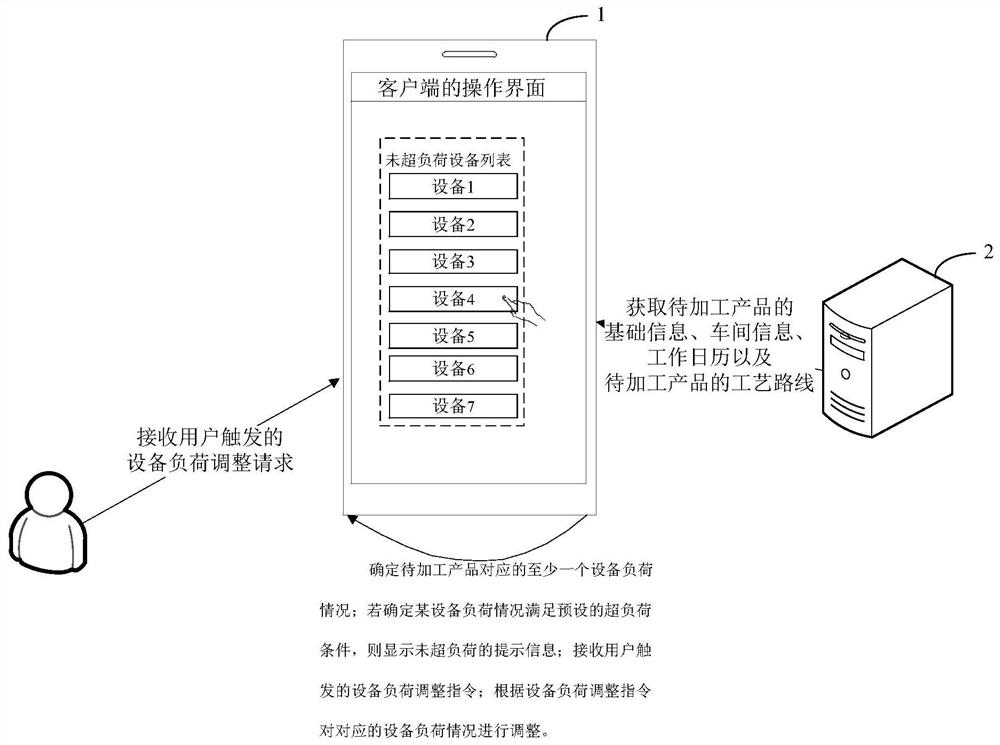

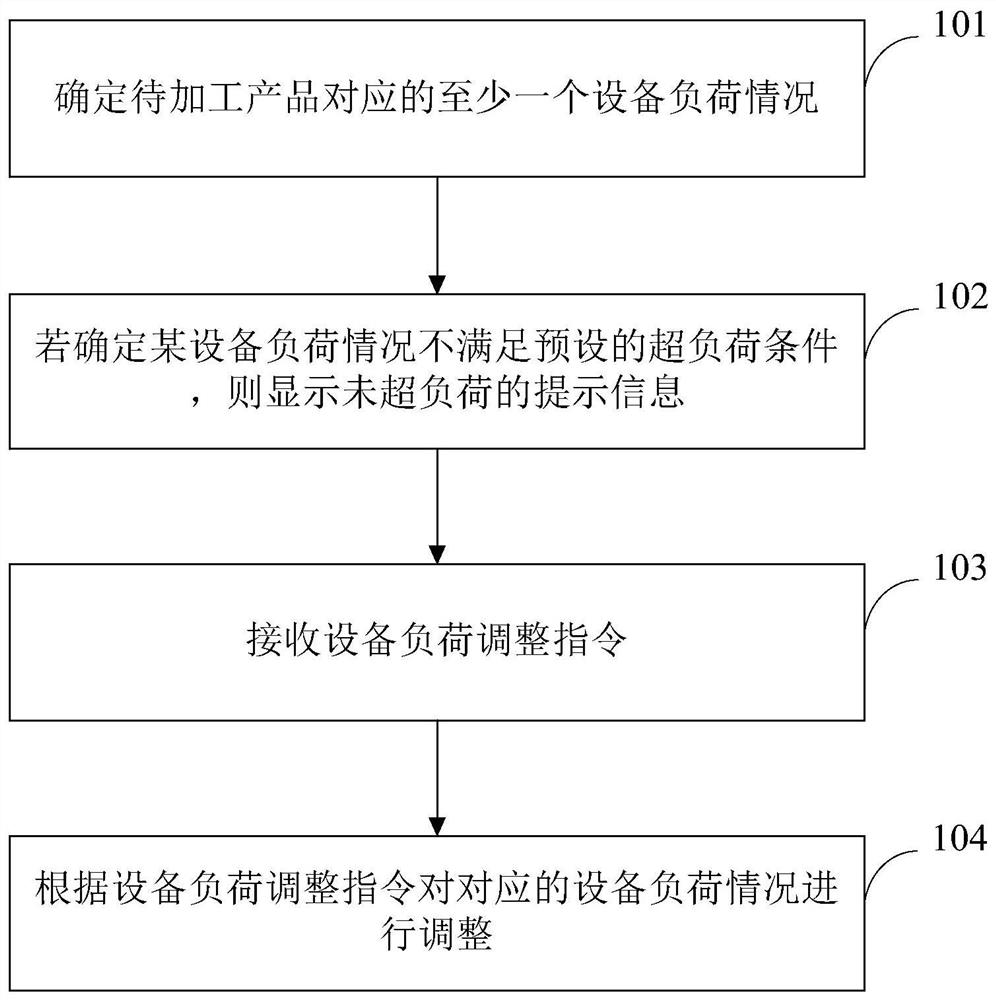

[0043] figure 2 is a schematic flow chart of the equipment load adjustment method provided in Embodiment 1 of the present invention, as shown in figure 2 As shown, the equipment load adjustment method provided in this embodiment is executed by the equipment load adjustment device, and the equipment load adjustment device is located in the electronic equipment, then the equipment load adjustment method provided in this embodiment includes the following steps:

[0044] Step 101, determining at least one equipment load situation corresponding to the product to be processed.

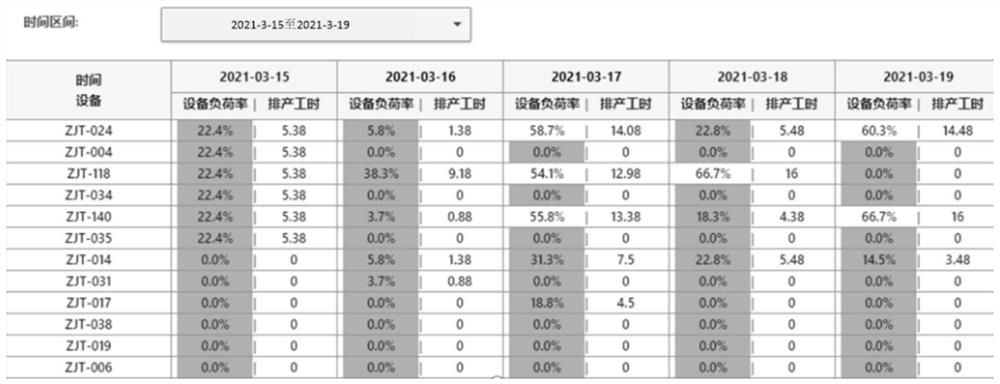

[0045] In this embodiment, the product to be processed will use a variety of equipment during the processing process, and the load of the equipment used by the product to be processed on a certain working day can be determined, and the equipment load is mainly represented by the equipment scheduling man-hour and equipment load rate . The production situation of the equipment can be known through the equi...

Embodiment 2

[0061] On the basis of the equipment load adjustment method provided in Embodiment 1 of the present invention, the following steps are included before step 102:

[0062] Step 102a, if it is determined that the load rate of a certain equipment is not less than the preset load rate, it is determined that the load of the equipment satisfies the preset overload condition.

[0063] In this embodiment, the equipment load conditions include the equipment load rate and the man-hours of equipment scheduling, and compare the equipment load rate of each equipment with the preset load rate. For example, if the preset load rate is set to 80%, then the equipment load rate Compared with 80%, the preset load rate can be set according to actual needs, and can also be other values. If the load rate of a certain equipment is not less than the preset load rate, it means that the workload of the equipment is arranged more, and the workload is relatively saturated. Make sure that the load of the eq...

Embodiment 3

[0068] Optionally, on the basis of the equipment load adjustment method provided in Embodiment 1 of the present invention, step 104 is further refined, and step 104 includes the following steps:

[0069] Step 1041, analyze the equipment load adjustment instruction, and obtain the equipment identification information in the load adjustment instruction.

[0070] In this embodiment, the user can open the web page or client of the application program based on the device load adjustment method of the present invention installed in the electronic device, and click the link of "adjust device load" on the web page or the preset operation interface of the client to select The equipment identification code triggers the equipment load adjustment instruction. After receiving the equipment load adjustment instruction triggered by the user, the equipment load adjustment instruction is analyzed to obtain the equipment identification information in the equipment load adjustment instruction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com