High-stability monocrystalline silicon differential pressure sensor

A high-stability, monocrystalline silicon technology, applied in the field of sensors, can solve problems such as difficult removal of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

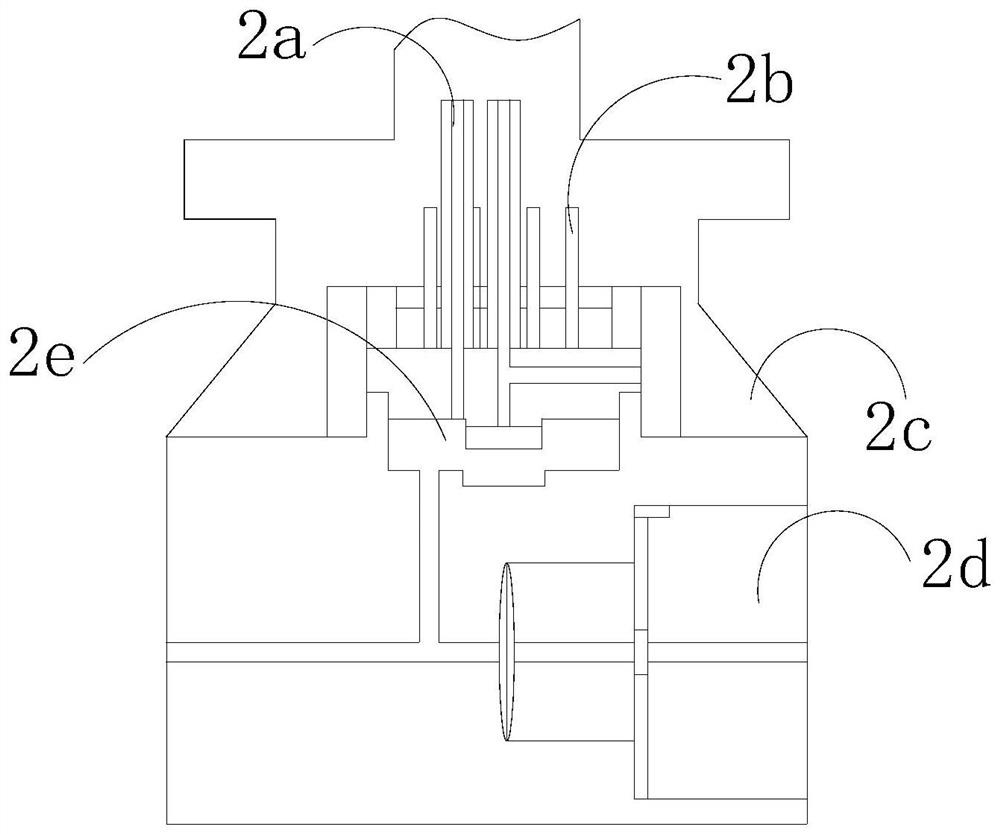

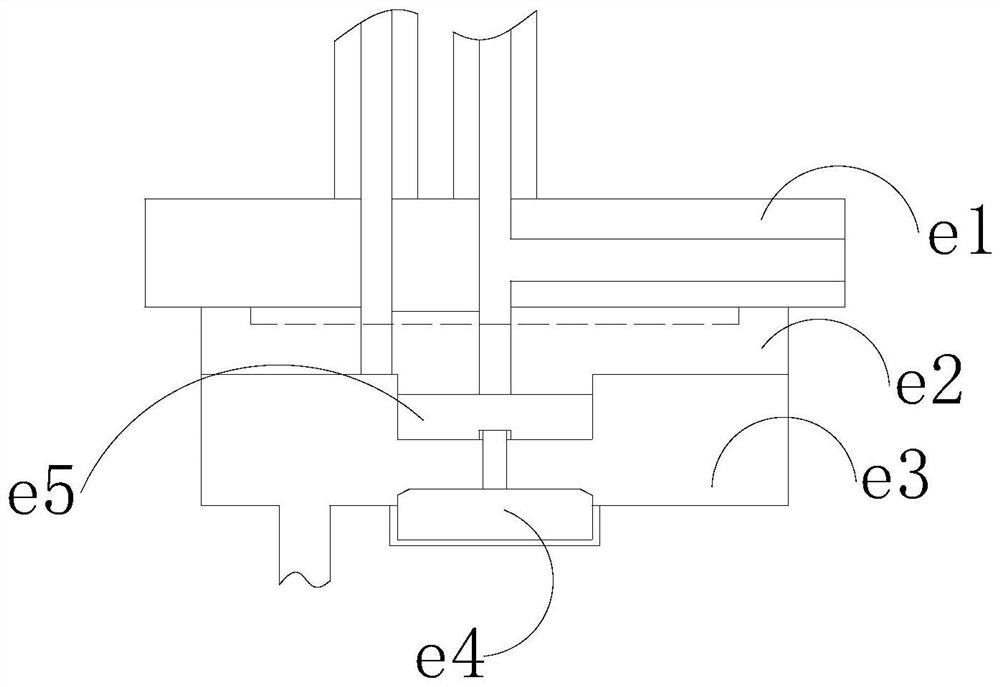

[0027] see Figure 1-Figure 5 , a high-stability monocrystalline silicon differential pressure sensor, its structure includes a connector 1, an operation box 2, and a base 3, the operation box 2 is provided with a connector 1, and the connector 1 is movably connected with the operation box 2 , the base 3 is installed on the operation box 2, and the operation box 2 is connected to the base in 3 directions;

[0028] The operation box 2 is provided with an oil filling pipe 2a, an electrical block 2b, a box body 2c, a pressure chamber 2d, and an operator 2e. The inside of the box body 2c is provided with an oil filling pipe 2a, and the oil filling pipe 2a is embedded with the box body 2c. Together, the electrical block 2b is installed on the box 2c, the box 2c is movably connected with the electrical block 2b, the operator 2e is installed on the box 2c, and the box 2c is connected to the operator 2e The pressure chamber 2d is installed inside the box body 2c, and the box body 2c ...

Embodiment 2

[0036] see Figure 1-Figure 6 , a high-stability monocrystalline silicon differential pressure sensor, its structure includes a connector 1, an operation box 2, and a base 3, the operation box 2 is provided with a connector 1, and the connector 1 is movably connected with the operation box 2 , the base 3 is installed on the operation box 2, and the operation box 2 is connected to the base in 3 directions;

[0037] The operation box 2 is provided with an oil filling pipe 2a, an electrical block 2b, a box body 2c, a pressure chamber 2d, and an operator 2e. The inside of the box body 2c is provided with an oil filling pipe 2a, and the oil filling pipe 2a is embedded with the box body 2c. Together, the electrical block 2b is installed on the box 2c, the box 2c is movably connected with the electrical block 2b, the operator 2e is installed on the box 2c, and the box 2c is connected to the operator 2e The pressure chamber 2d is installed inside the box body 2c, and the box body 2c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com