A solid-liquid separation non-clogging pump

A non-clogging pump, separate technology, used in pumps, pump components, non-variable-capacity pumps, etc., can solve problems such as increasing energy consumption, shortening pump service life, and reducing efficiency, reducing load, reducing impact loss, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

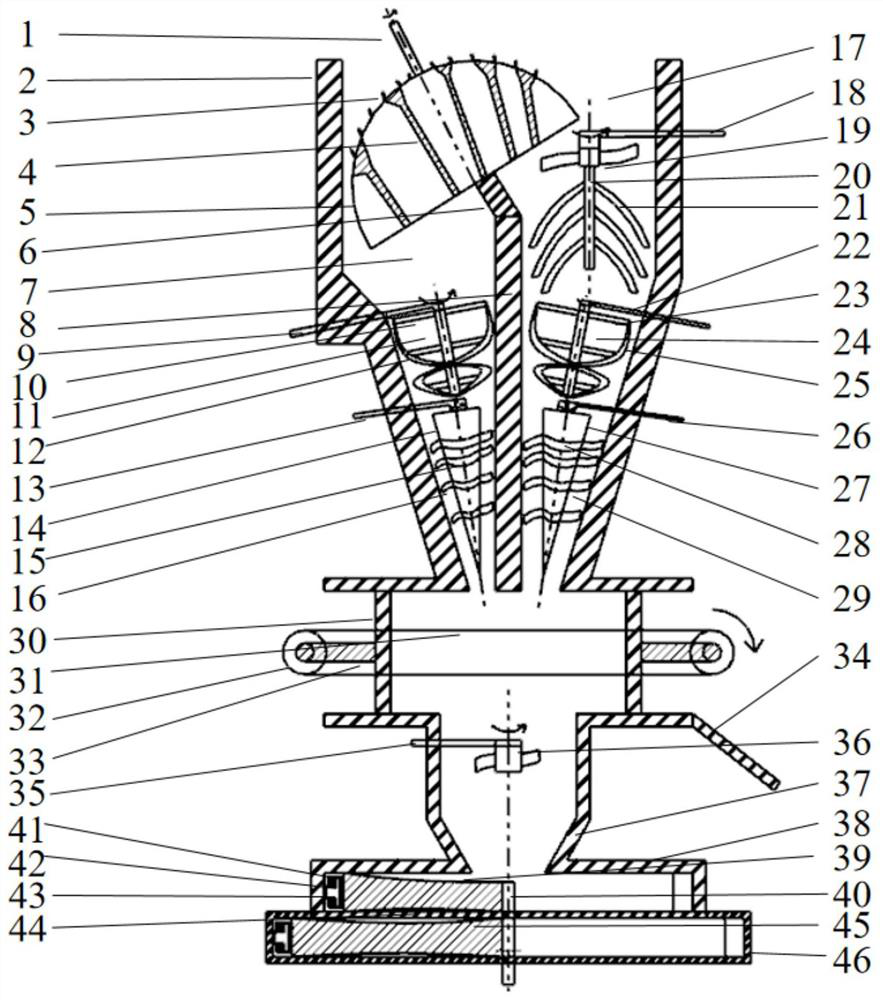

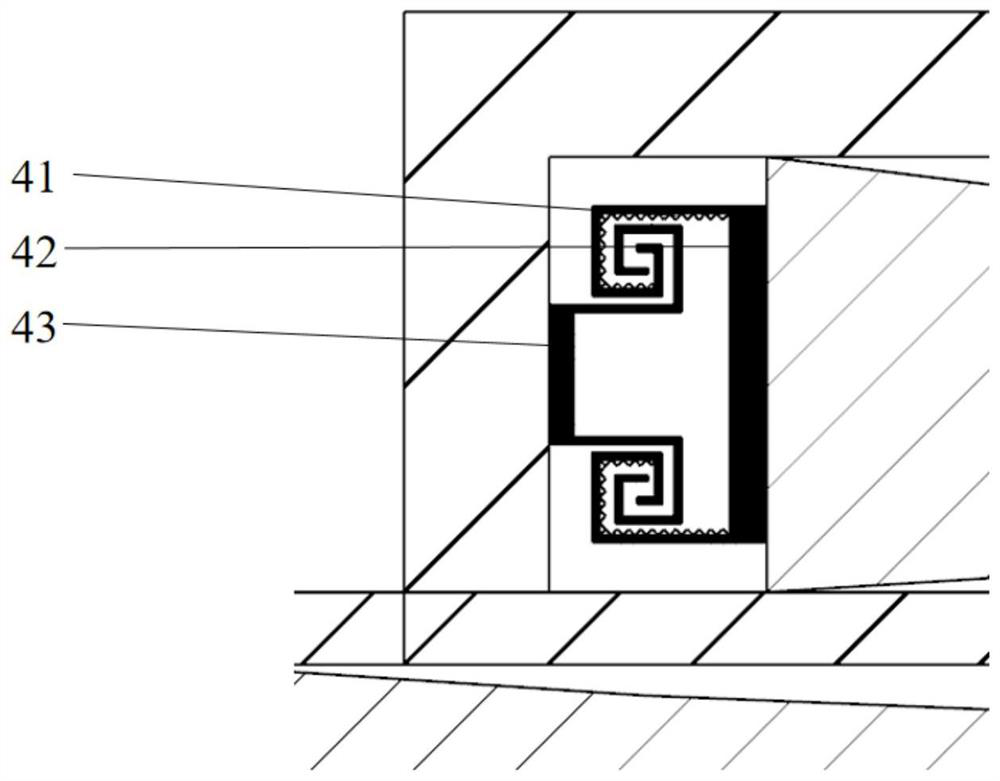

[0031] like figure 1 As shown in the figure, a solid-liquid separation type non-clogging pump according to the present invention includes a solid particle separator 5, a small particle crushing chamber 7, a large particle crushing chamber 17, and a two-chamber partition plate 8, which are arranged in sequence from top to bottom. , Particle conveying device, bracket 30, front impeller 36, conical flow channel 37, first stage volute 38, first stage impeller 39, second stage volute 46, second stage impeller 45. The solid particle separator 5 is hemispherical, and the two-chamber partition plate 8 completely separates the small particle crushing chamber 7 and the large particle crushing chamber 17 without interfering with each other, and the partition plate can be adjusted acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com