Novel vacuum flushing device

A technology of flushing device and vacuum, applied in water supply device, grease/oily substance/float removal device, cleaning of sewer pipes, etc., can solve problems such as increasing the pressure of water storage chamber, prevent clogging, ensure fixation, and improve leakage. The effect of pressure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

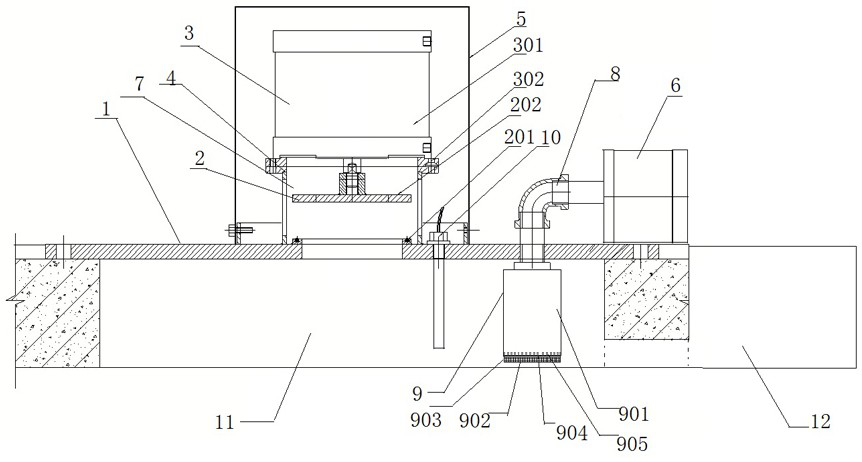

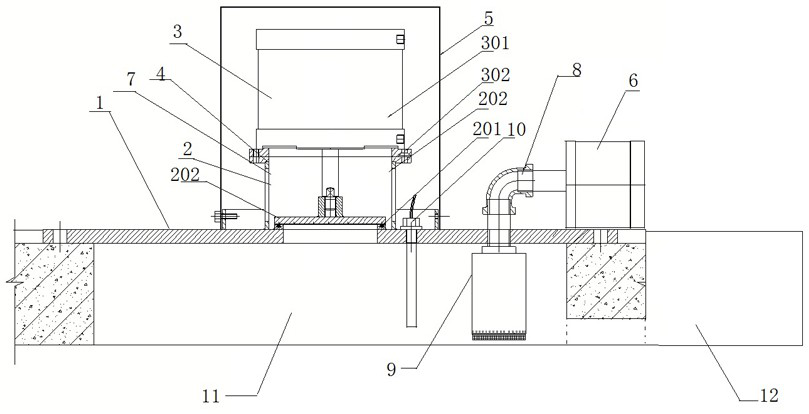

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

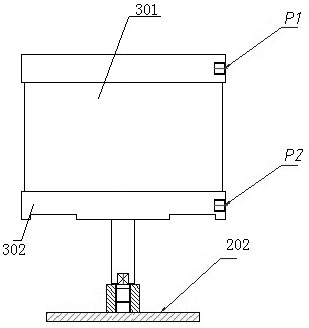

[0023] A novel vacuum flushing device, comprising a base 1 fixed on the top of the water storage chamber and a vacuum pump 6 arranged on the base to suck air, one end of the vacuum pump 6 is connected to a vacuum pipeline 8, and the other end of the vacuum pipeline 8 is provided In the water storage chamber, the upper end of the base 1 is provided with a pressure increasing and releasing mechanism, and the pressure increasing and releasing mechanism includes a sealing assembly 2 and a lifting assembly 3, the sealing assembly 2 is arranged on the upper end of the base 1, and the upper end of the sealing assembly 2 is provided There is a lifting assembly 3, the lifting part of the lifting assembly 3 is fixedly connected with the sealing assembly 2 so as to drive it to move up and down, the connecting parts at both ends of the lifting assembly 3 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com