Surface embossing device for electronic product production

An electronic product and surface pressing technology, which is applied in decorative arts, painting tools, embossed ornaments, etc., can solve the problems of difficult replacement of embossed patterns, low stability, and easy deviation of embossed positions, so as to increase stability and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

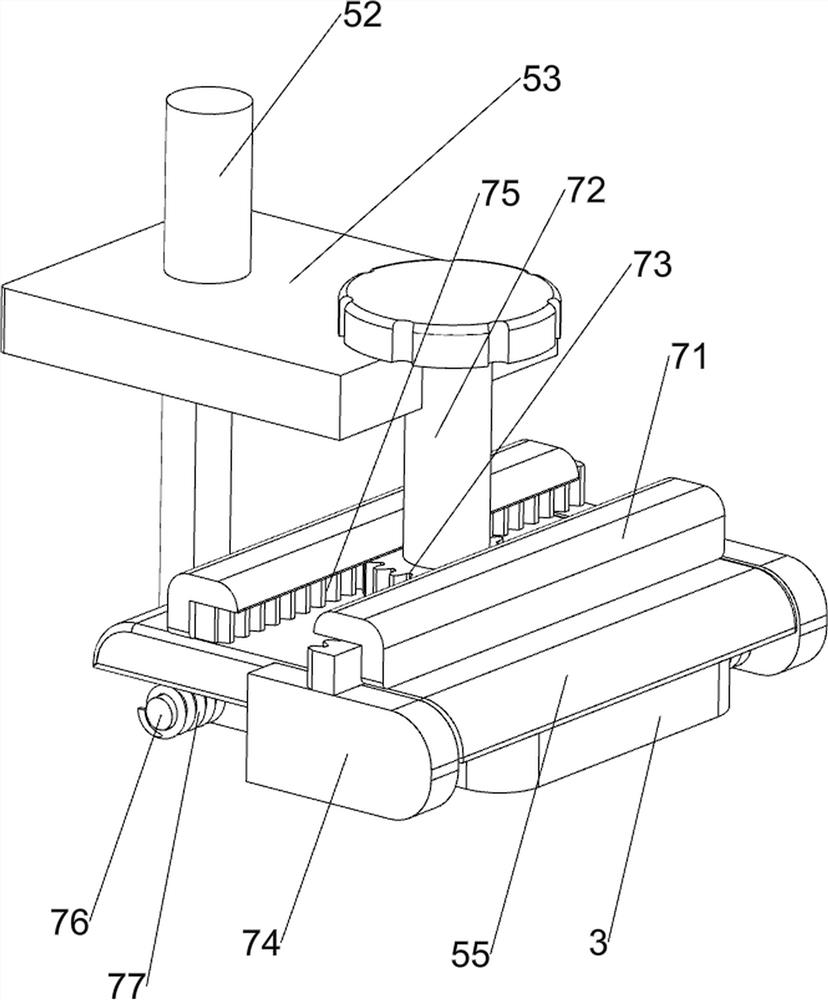

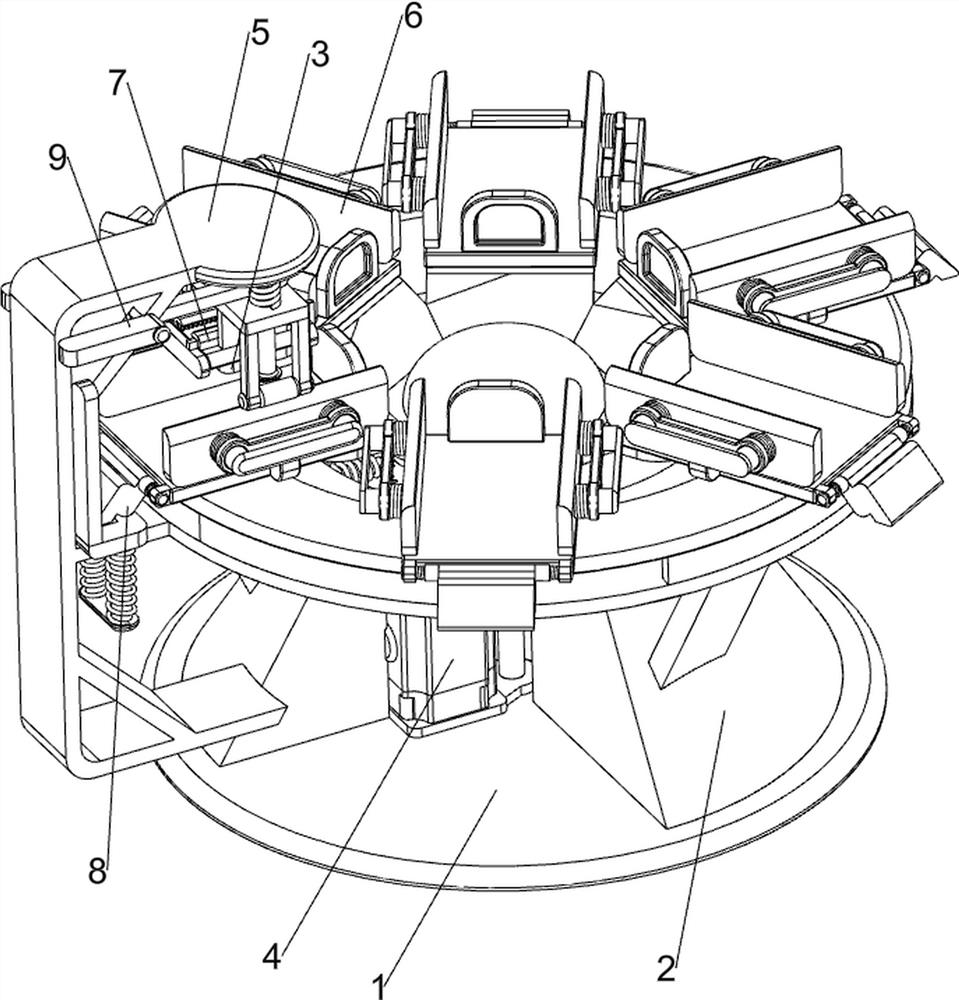

[0038] A surface embossing device for the production of electronic products, such as Figure 1-Figure 8 As shown, it includes a chassis 1, a supporting frame 2, an embossing block 3, a rotating mechanism 4 and an embossing mechanism 5. The top of the chassis 1 is provided with a supporting frame 2, and the inner side of the supporting frame 2 is provided with a rotating mechanism 4. The left side of the supporting frame 2 An embossing mechanism 5 is provided, and an embossing block 3 is arranged on the embossing mechanism 5, and the left and right sides of the embossing block 3 are symmetrically provided with grooves.

[0039]The rotating mechanism 4 includes a first limiting block 41, a reduction motor 42, a missing gear 43, a first rotating shaft 44, a first gear 45, a connecting plate 46 and a placement plate 47, and a first limiting block is arranged in the middle of the lower side of the support frame 2. Bit block 41, first limit block 41 top is provided with deceleration...

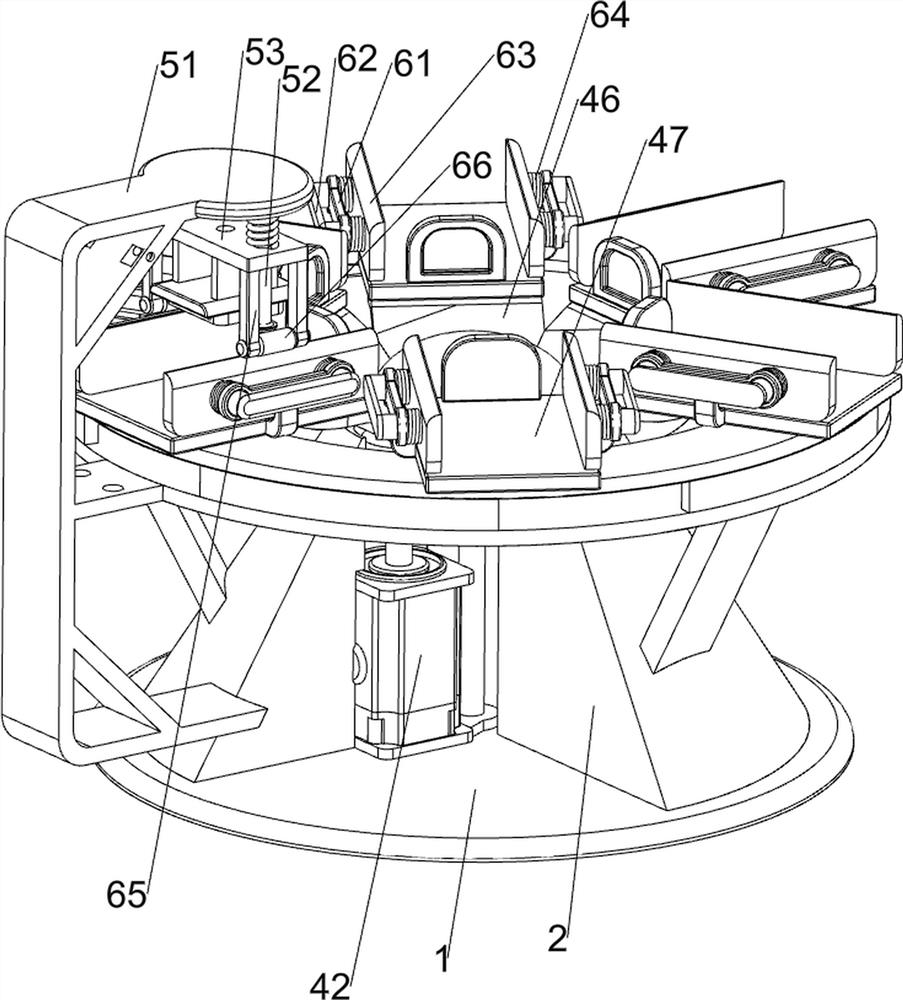

Embodiment 2

[0043] On the basis of Example 1, such as Figure 9-Figure 18 As shown, the clamping assembly 6 is also included, and the clamping assembly 6 includes a guide block 61, a push rod 62, a clamping plate 63, a second spring 64, a connecting rod 65 and a roller 66, and the placing plate 47 is provided with two A guide block 61, the inner upper side of the guide block 61 is all slidingly provided with a push rod 62, and the inside of the push rod 62 is provided with a clamping plate 63, and the clamping plate 63 is located on both sides of the top of the placement plate 47, and the clamping plate 63 is connected to the top of the plate 47. The second spring 64 is arranged symmetrically between the guide blocks 61 , the front and rear sides of the bottom of the slide plate 53 are provided with connecting rods 65 , and the lower side of the connecting plate 46 is rotatably provided with rollers 66 , and the rollers 66 cooperate with the clamping plate 63 .

[0044] When the slide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com