Machining method for bypass branch pipe of pipeline

A processing method and bypass technology, applied in the field of pipe fittings processing, can solve the problems of poor precision, high processing difficulty and low efficiency, and achieve the effects of improving precision and quality, good uniformity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

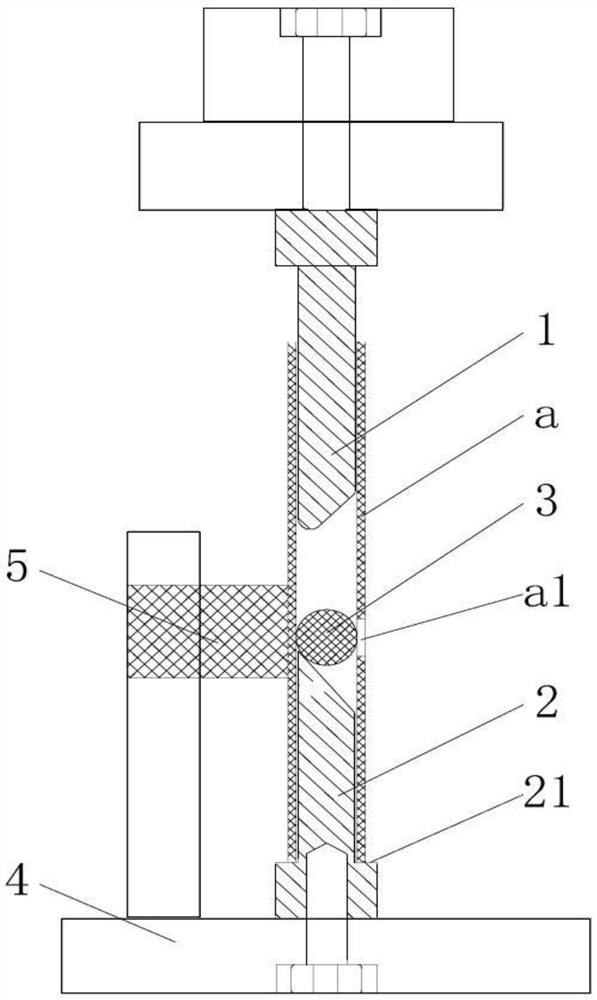

[0033] A method for processing a bypass branch pipe of a pipeline mainly includes the following steps:

[0034] A. Open a hole at a predetermined position on the wall of the main pipe a to form a side wall hole a1;

[0035] The side wall hole a1 can be processed by cutting or punching;

[0036] When using the punching method to process the side wall hole a1, the punching die with the slot hole is placed into the main pipe a, and the slot hole of the punching die is facing the position where the side wall hole a1 needs to be processed in the main pipe a, and The punching die matched with the punching die is driven by the stamping mechanism to punch the punching die from the outside of the pipe wall of the main pipe a, and the punching die passes through the pipe wall of the main pipe a and enters the punching die to obtain the side wall hole a1, then the punching die exits in reverse and the punching die exits from the inside of the main pipe a;

[0037] B. Reaming the side wal...

Embodiment 2

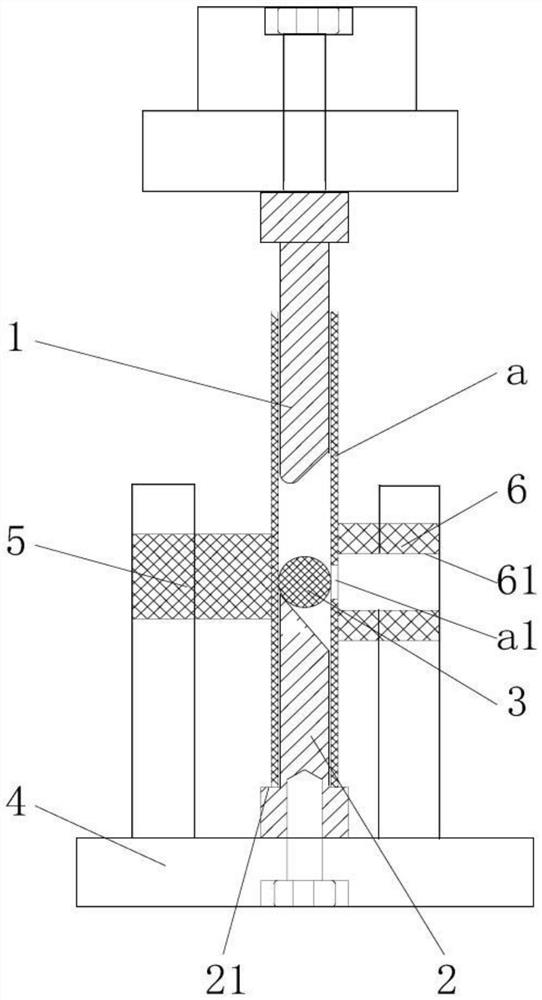

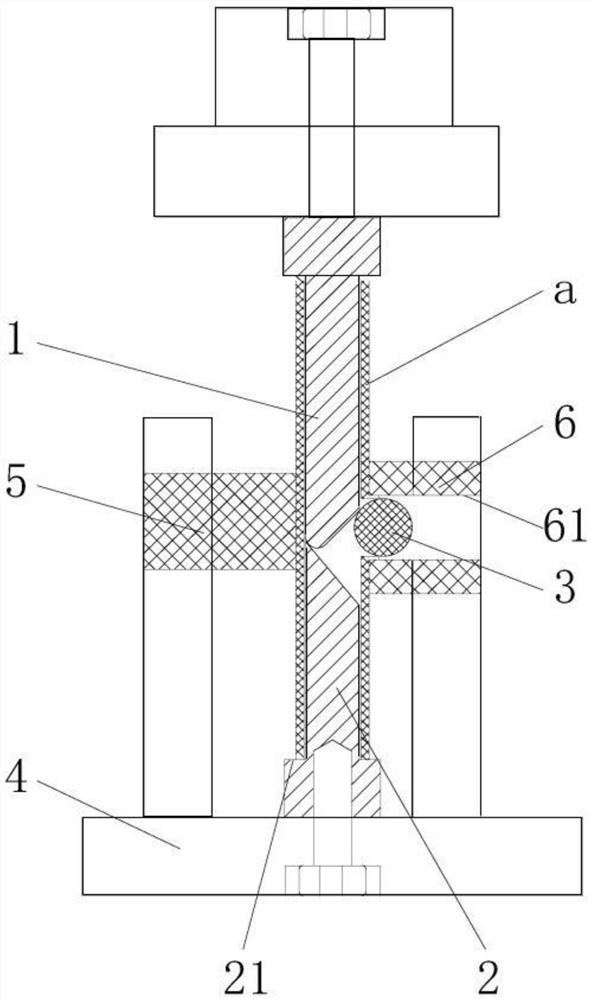

[0044] A method for processing a bypass branch pipe of a pipeline mainly includes the following steps:

[0045] A. Open a hole at a predetermined position on the wall of the main pipe a to form a side wall hole a1;

[0046] The side wall hole a1 can be processed by cutting or punching;

[0047] When using the punching method to process the side wall hole a1, the punching die with the slot hole is placed into the main pipe a, and the slot hole of the punching die is facing the position where the side wall hole a1 needs to be processed in the main pipe a, and The punching die matched with the punching die is driven by the stamping mechanism to punch the punching die from the outside of the pipe wall of the main pipe a, and the punching die passes through the pipe wall of the main pipe a and enters the punching die to obtain the side wall hole a1, then the punching die exits in reverse and the punching die exits from the inside of the main pipe a;

[0048] B. Reaming the side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com