Shoe pattern printing method

A printing method and pattern technology, applied in footwear, shoe-making machinery, clothing and other directions, can solve the problems of low work efficiency, ink easily affects the skin of the hand, blurred patterns, etc., to improve efficiency, uniform and stable shoe printing, clear pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

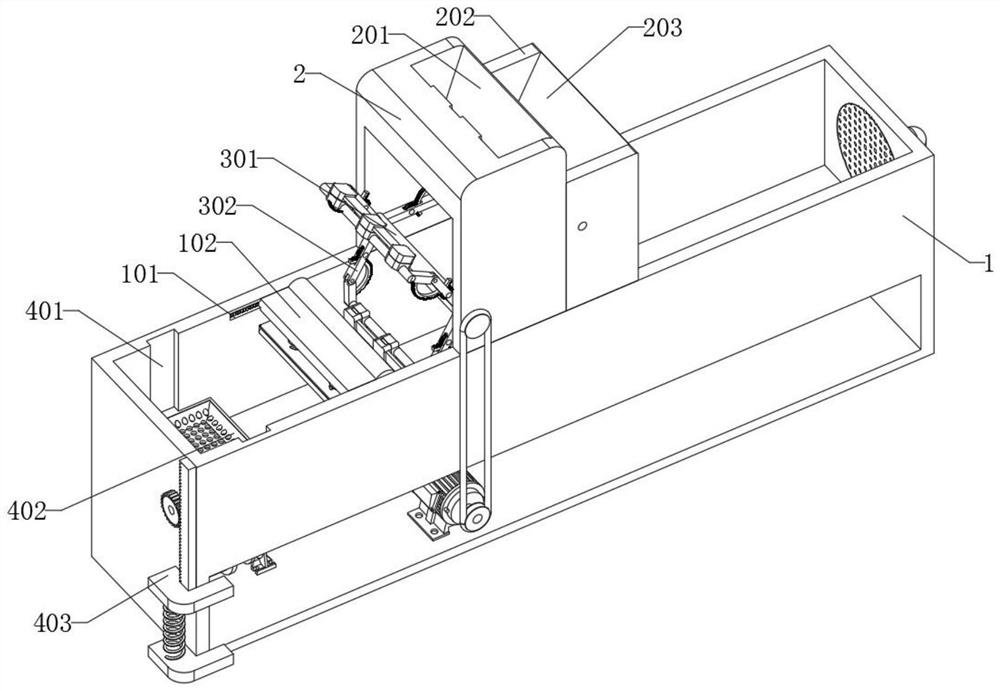

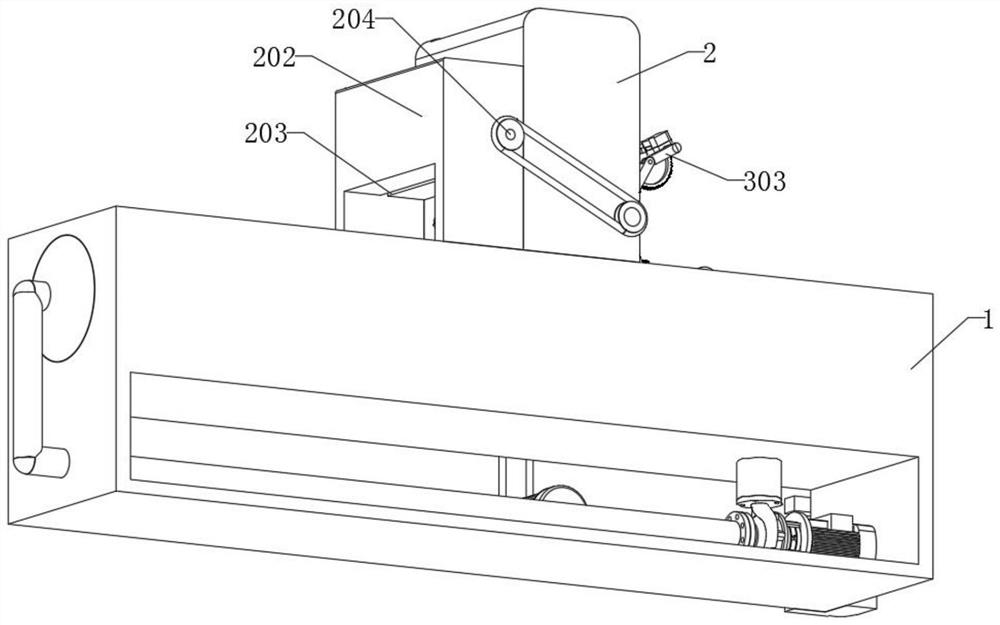

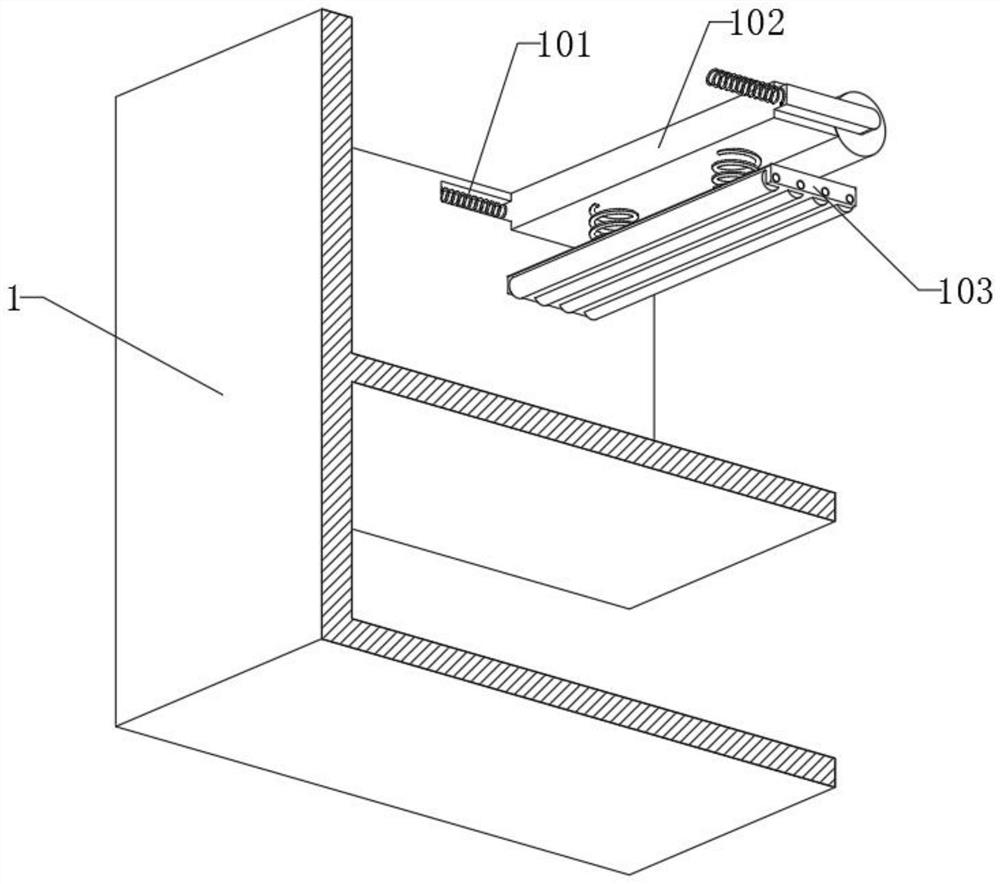

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The present invention provides a shoe pattern printing method. The shoe pattern printing method is completed by using shoe pattern printing equipment, thereby realizing efficient printing of shoe patterns; the shoe pattern printing equipment includes:

[0036] Main body 1, a motor and a water circulation pump are respectively installed on the inner side of the bottom of the main body 1, and a box body 2 is installed on the top of the main body 1; box body 2, the box body 2 is a rectangular structure, and the vertical plate 202 on the side of the box body 2 is located The top of the main body 1; the transmission part 3, the transmission part 3 is installed at the bottom of the box body 2, and the rotating rod 301 in the transmission part 3 is installed at the bottom of the box body 2, and the side end of the rotating rod 301 passes through the pulley and the bottom of the main body 1 The inner motors are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com