Nuclear power generator stationary blade seat disassembling and assembling tool and method

A technology for generators and generator rotors, which is applied in the field of maintenance of nuclear power plants, and can solve problems such as overhaul delays, equipment damage, and stator blade bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

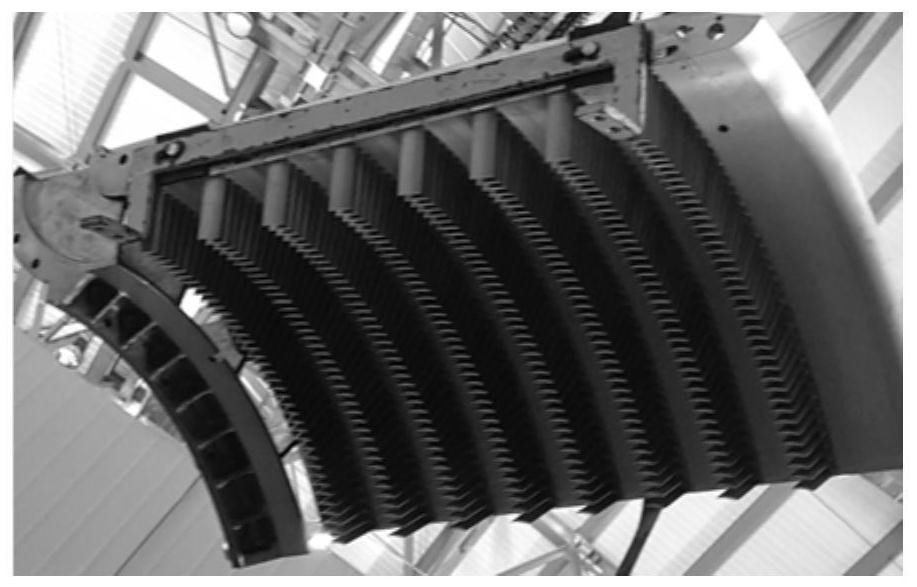

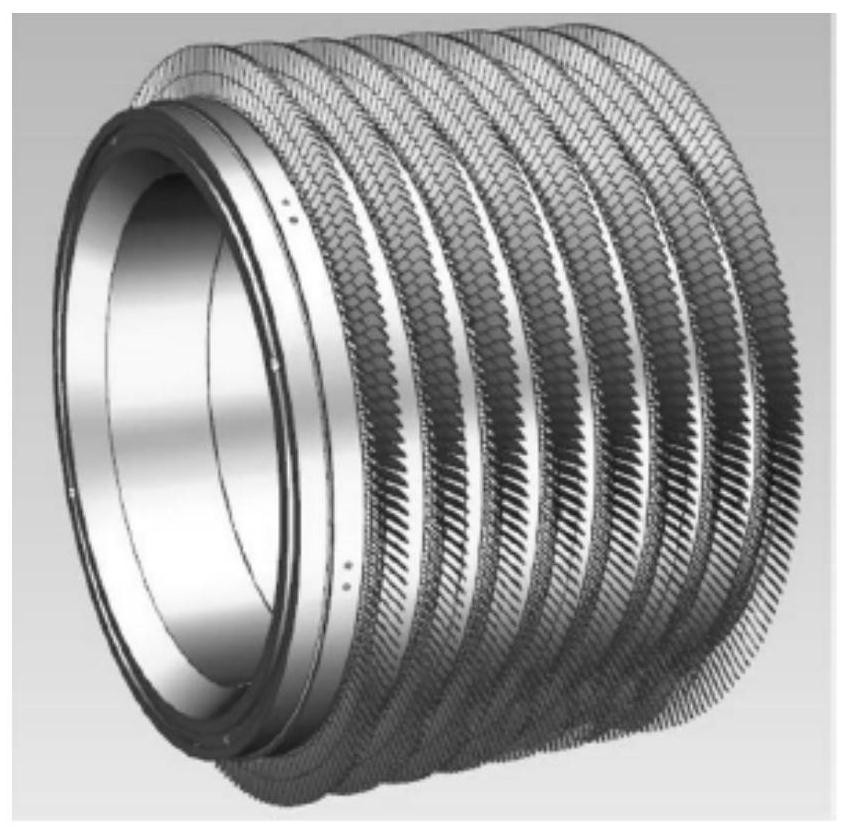

[0049] This embodiment provides a disassembly and assembly tool for a stator blade seat of a nuclear power generator. see Figure 4 , the dismounting tool includes a crossbeam slide rail 1; the bottom of the crossbeam slide rail 1 is provided with a first suspension block 4 and a second suspension block 6 that can slide along the crossbeam slide rail 1, and the first suspension block The lower end of 4 and the lower end of the second hanging block 6 are respectively connected to the first chain block 5 and the second chain block 7; Two installation parts 3; the first installation part 2 and the second installation part 3 are used for fixed connection with the generator base; the first chain hoist 5 and the second chain hoist 7 are used for hooking respectively At the front and rear ends of the vane seat. By using the dismounting tool, the hoisting and translation of the stator blade seat can be realized, and the stator blade seat can be driven to rotate around the central ax...

Embodiment 2

[0085] This embodiment provides a method for disassembling and assembling a stator blade seat of a nuclear power generator.

[0086] The disassembly method comprises the steps of:

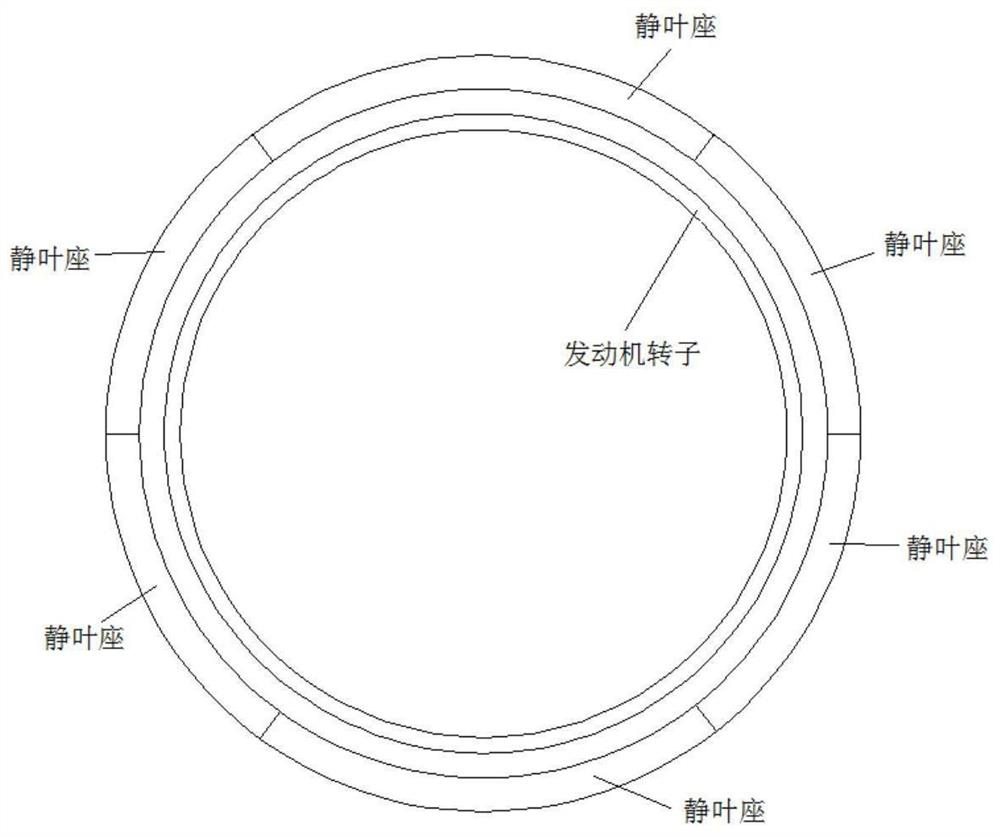

[0087] Step S1, removing a vane seat directly above the generator rotor;

[0088] Step S2, using the dismounting tool to lift out the stator blade seat directly above the generator rotor;

[0089] Step S3, using the dismounting tool to rotate the vane seat located at the upper left of the generator rotor around the axis of the generator rotor to directly above the generator rotor, and then implement step S2;

[0090] Step S4, using the disassembly tool to rotate the vane seat located at the upper right of the generator rotor around the axis of the generator rotor to directly above the generator rotor, and then implement step S2;

[0091] Step S5, after fixing the stator blade seat on the lower side of the generator rotor, rotate the rotor to turn the stator blade seat on the lower side of the gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com