A comprehensive cooling motor

A motor shaft and motor housing technology, applied in the field of comprehensive heat dissipation motors, can solve problems such as poor motor heat dissipation effect, achieve good heat dissipation effect, and solve the effect of poor heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Such as figure 1 As shown, the comprehensive heat dissipation motor of this application includes a motor body 100, a water cooling heat dissipation system 200 and a control unit;

[0078] The motor main body 100 includes a motor housing 110, a stator, a rotor and a motor shaft 120; the motor housing 110 is the casing of the motor, which supports the stator and the motor shaft 120; the motor shaft 120 Through the motor housing 110 , one end of the motor shaft 120 away from the heat dissipation pipe 214 of the water cooling system 200 is the first output end 121 , and the other end of the motor shaft 120 is the second output end 122 .

[0079] The water-cooling heat dissipation system 200 is used to dissipate heat from the motor, which includes a medium delivery pipe 210 and a water pump 220; the medium delivery pipe 210 is used to deliver heat dissipation medium, which includes a water delivery pipe 211 in the housing, a connecting pipeline 212, rotary water delivery as...

Embodiment 2

[0102] In order to compensate for the loss of the heat dissipation medium in the flow and consider the thermal expansion and contraction of the heat dissipation medium; preferably, the integrated heat dissipation motor of this application further includes a water tank assembly 300, and the water tank assembly 300 is positioned on the motor housing 110, It communicates with the medium conveying pipe 210 described above.

[0103] In order to further reduce the risk of motor overheating and damage to the motor, preferably, the water tank assembly 300 includes a water tank main body, a water spray assembly 310 and a switching valve 320; the spray head of the water spray assembly 310 faces the heat dissipation water pipe 214; The switching valve 320 is positioned inside the main body of the water tank, and is used to control the flow of liquid inside the main body of the water tank and then control the operation of the water spray assembly 310; Figure 9 As shown, the control unit ...

Embodiment 3

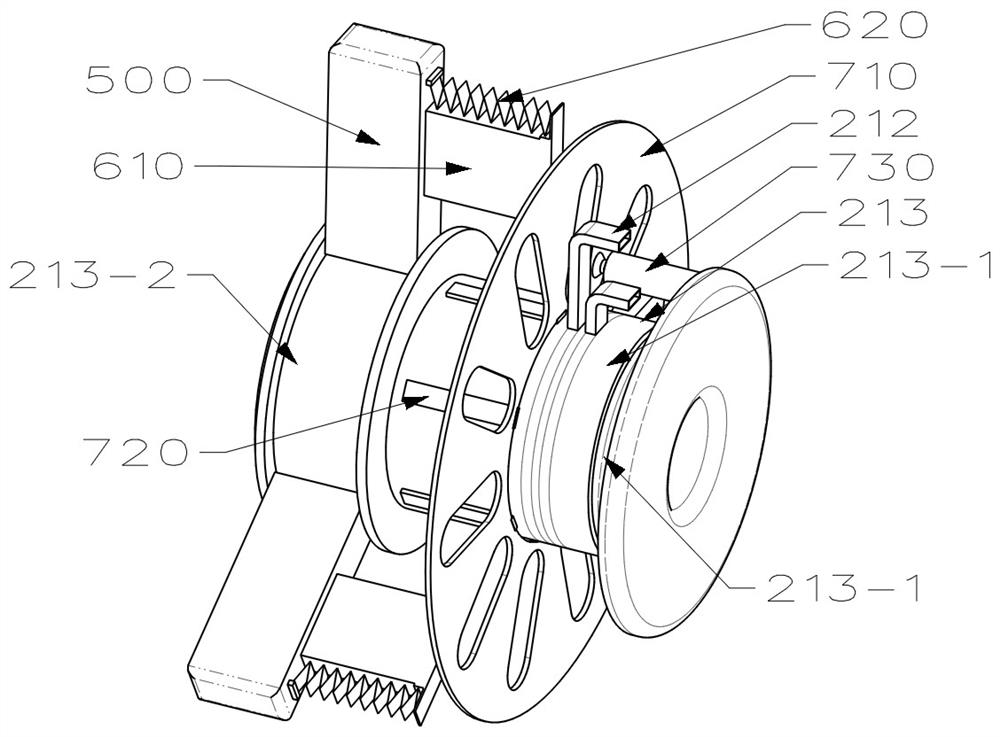

[0109] In order to further improve the efficiency of heat dissipation of the motor, this implementation adds a cooling assembly 600 on the basis of the above-mentioned embodiments, and carries out related modifications to the heat dissipation plate assembly 500, specifically:

[0110] The cooling plate assembly 500 includes a through groove 510, and the cooling assembly 600 includes a cooling sheet 610, a power supply assembly and a cooling sheet positioning assembly 620; the cooling sheet 610 is a semiconductor cooling sheet, which passes through the cooling sheet The positioning component 620 is positioned on the through slot 510 , and the power supply component is used to provide power for the operation of the cooling plate 610 .

[0111] Preferably, the number of said through grooves 510 is one or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com