An anti-jamming bar blanking machine for the production of new energy automobile connectors

A new energy vehicle and connector technology, applied in vehicle connectors, connections, electrical components, etc., can solve the problems of bar bending and deformation, affecting production efficiency, bar crossing disorder, etc., and achieving the effect of preventing material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

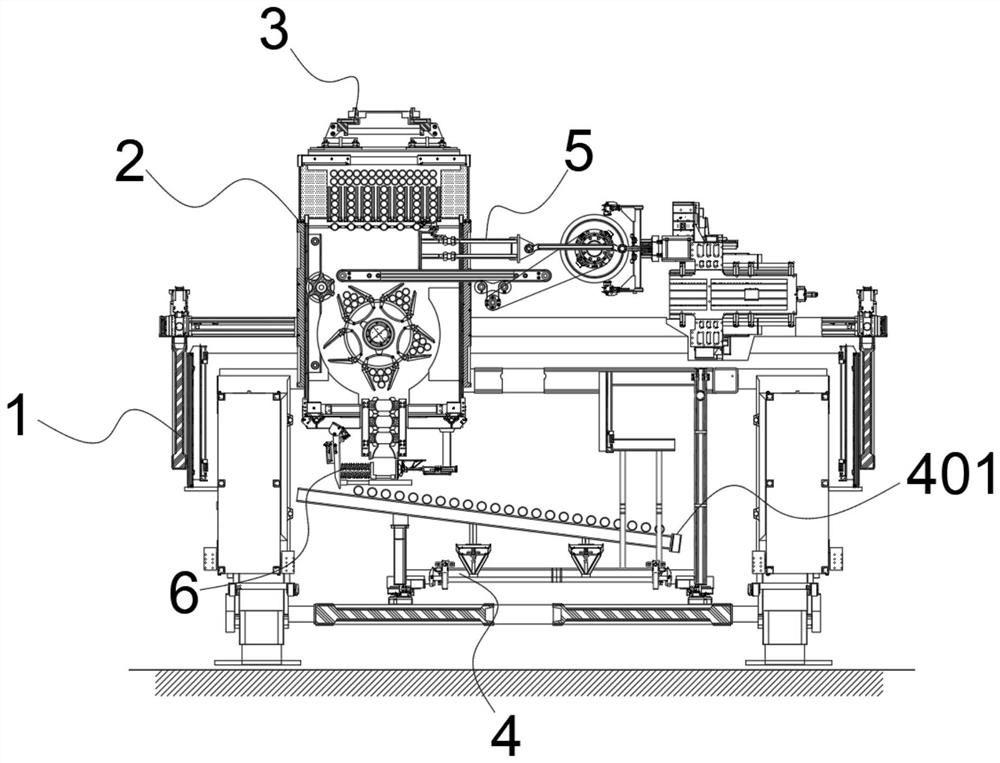

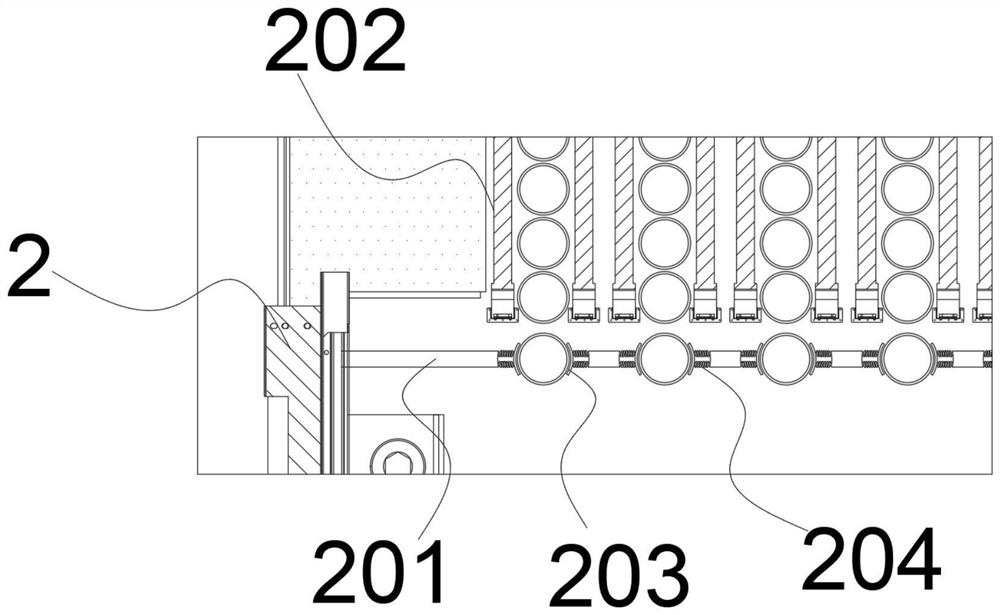

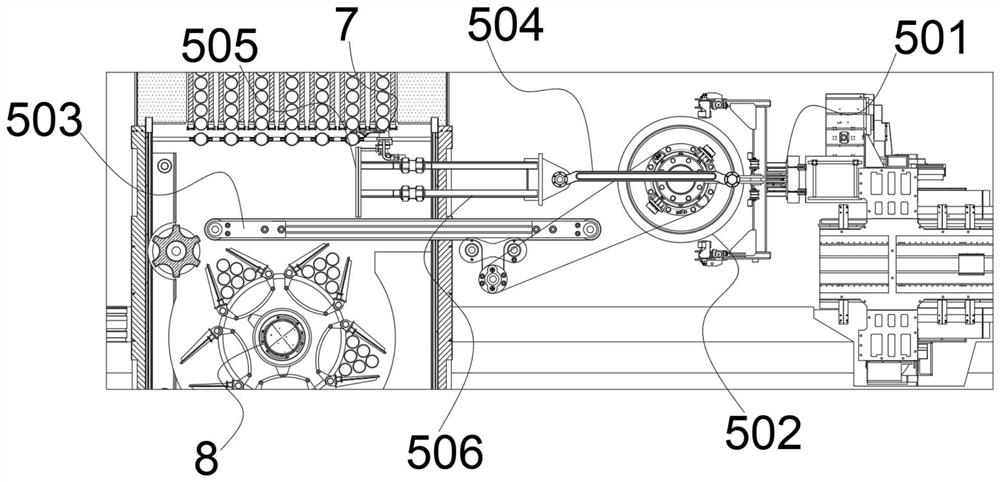

[0037] see figure 1 , in an embodiment of the present invention, an anti-jamming bar blanking machine for the production of new energy automobile connectors, which includes: a frame main body 1, a feeding end piece 3, a carrying material box 2, an internal fixing bracket 4, Conveying beam 401 and built-in discharge assembly 5; wherein, the inner middle side of the frame main body 1 is provided with a placement cavity, and the inner lower side of the placement cavity is provided with an internal fixing bracket 4, and the delivery beam The two ends of 401 are erected obliquely in the frame main body 1 through the internal fixing bracket 4 respectively, and the upper end surface of the frame main body 1 is located at the inclined high side of the conveying beam 401 and is vertically embedded with a carrying material box 2; The inclined low position of the conveying beam is connected with an external processing device (not shown in the figure), which is used to sequentially proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com