Energy-saving high-pressure fluidization fan device for circulating fluidized bed boiler

A circulating fluidized bed and fan technology, which is applied to the components, pump devices, mechanical equipment, etc. of the pumping device for elastic fluids, to achieve the effects of reducing wear, prolonging service life, and reducing axial movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

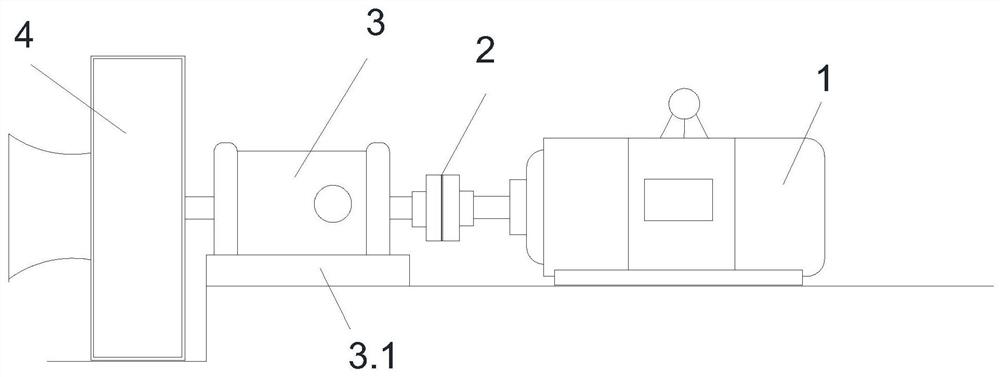

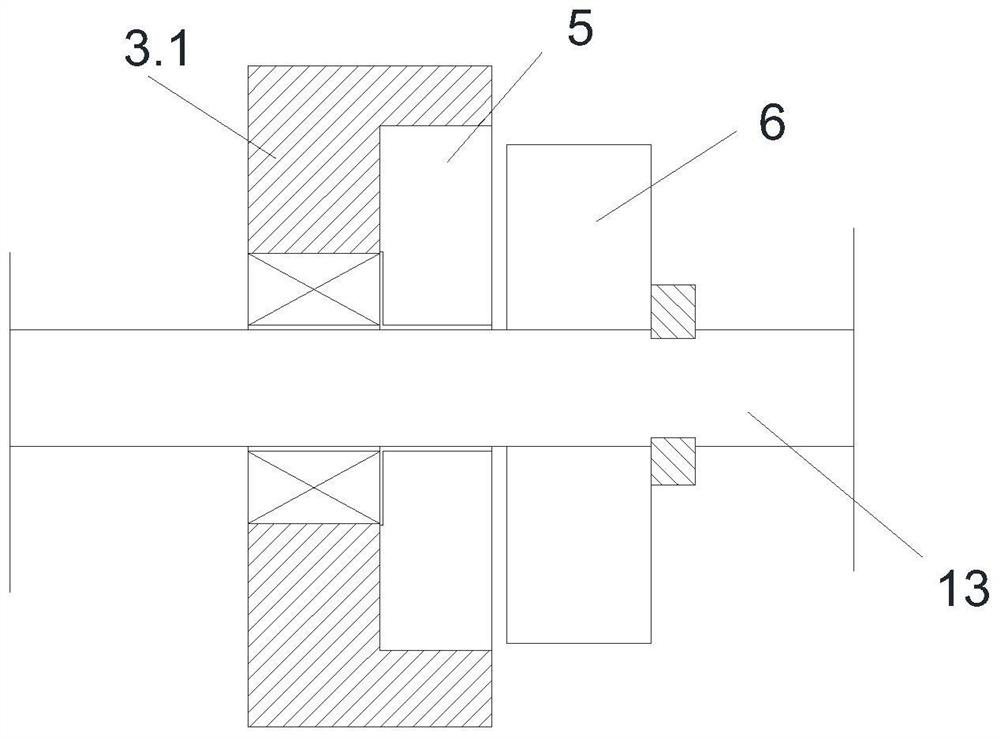

[0030] Such as Figure 1-7 As shown, an energy-saving high-pressure fluidized fan 4 device for a circulating fluidized bed boiler provided by an embodiment of the present invention includes a motor 1, a coupling 2, a transmission seat 3 and a fan 4 that are sequentially connected by transmission. The base 3.1 of the seat 3 is provided with an electromagnet 5, and the central shaft 13 of the fan 4 is provided with a magnetic chuck 6, and the electromagnet 5 is located on the axial movement stroke of the magnetic chuck 6 and there is a gap between the two. magnetic repulsion.

[0031] Specifically, in the prior art, the motor 1, the coupling 2, the transmission seat 3 and the fan 4 are connected in sequence to realize the drive of the motor 1 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com