Automatic anchor bolt thermal shrinkage production line

A production line and anchor bolt technology, which is applied in the field of automatic heat shrinkable anchor bolt production line, can solve the problems of low production efficiency and high labor intensity of workers, and achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

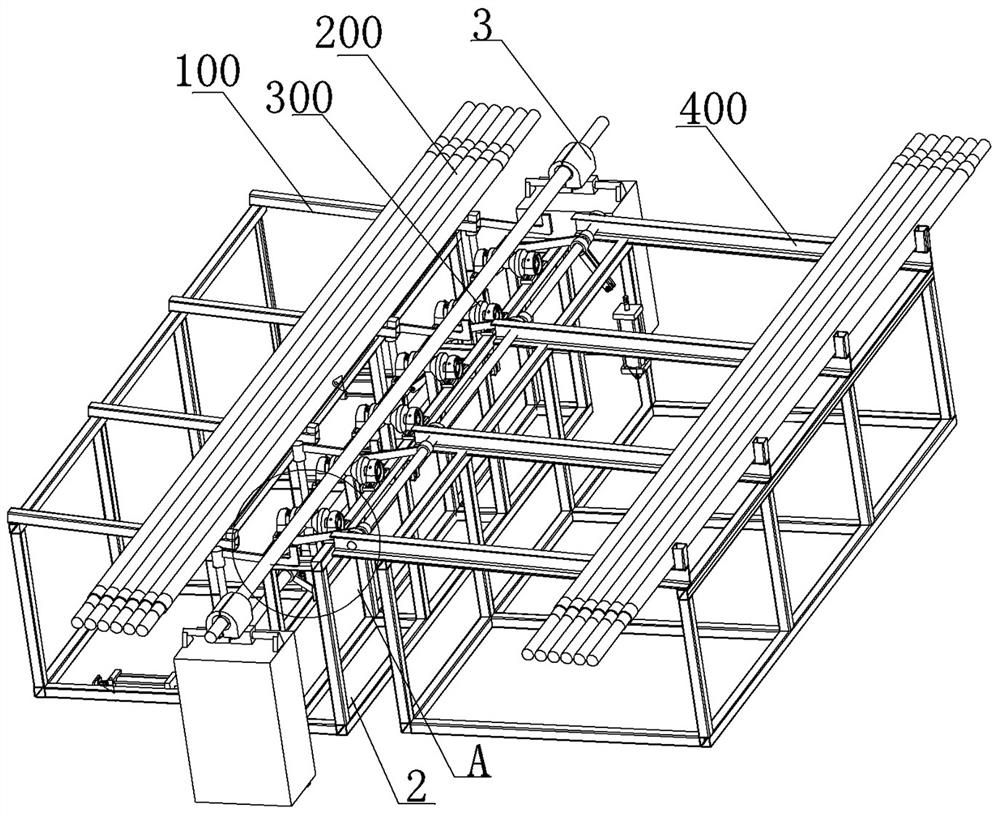

[0051] In this example, if Figure 1 to Figure 8 As shown, the anchor bolt automatic heat shrink production line includes a feeding unit 100, a heat shrink unit 300, and a material receiving unit 400 arranged in sequence along the front and rear directions. When in use, the anchor bolt 200 stored on the feeding unit 100 is used The single anchor bolts are transported one by one to the single anchor bolt processing position 301 of the heat shrink unit 300, and the single anchor bolt 200 is heat-shrinked by the heating machine 3 according to the predetermined production cycle. 200 is transferred to the material receiving unit 400 to realize the automatic heat shrinking processing of the anchor bolt 200.

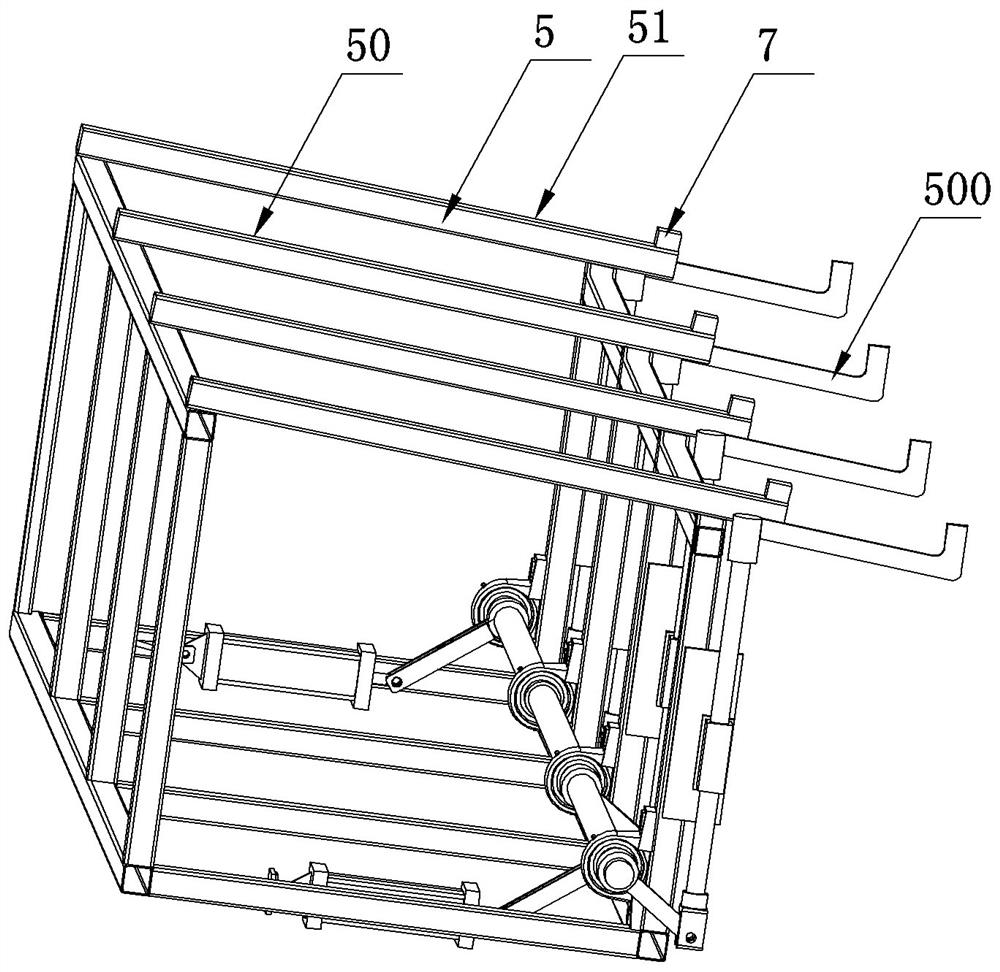

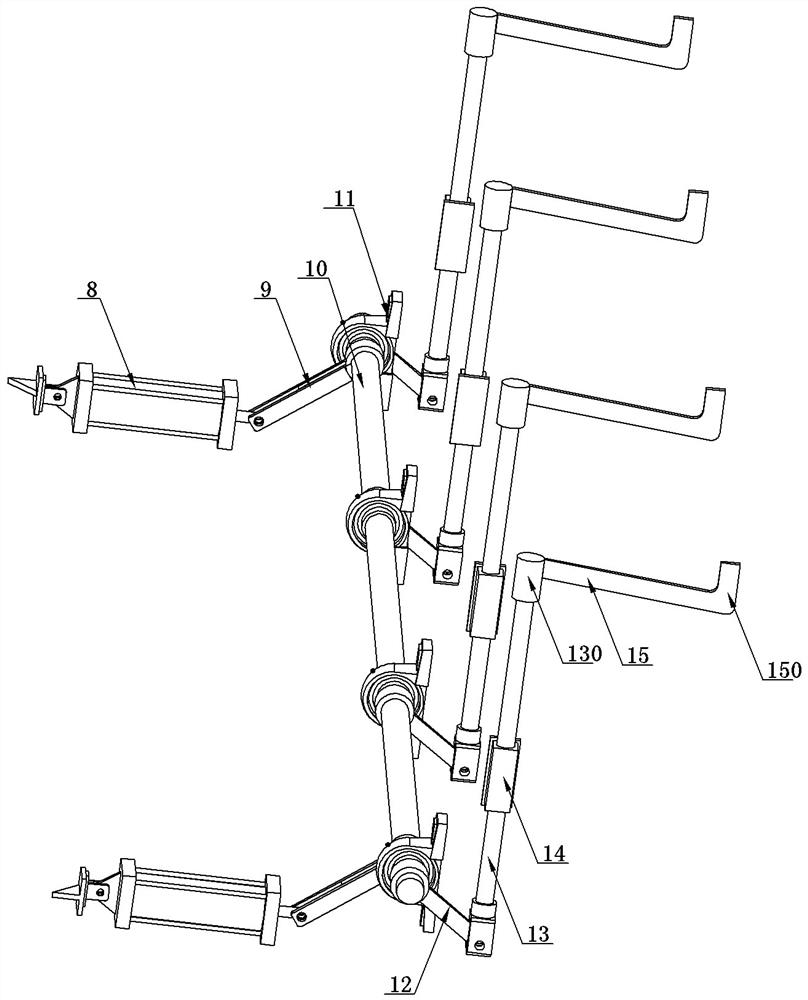

[0052] The feeding unit 100 is used to store the anchor bolts 200 to be heat-shrinked, and the specific structure is as follows: figure 1 , figure 2 , image 3 and Figure 8 As shown, the feeding unit 100 includes a feeding platform 5 and a feeding mechanism 500, and the f...

specific Embodiment 2

[0072] The main difference between it and Embodiment 1 is that in Embodiment 1, the feeding platform of the feeding unit has a feeding support surface, which is convenient for arranging multiple anchor bolts in a single layer. In this embodiment, the feeding unit can also be connected to other feeding production lines, and the single anchor bolt is delivered by the feeding production line, and then the single anchor bolt is transferred to the single anchor bolt processing position of the heat shrinking unit by the feeding mechanism, so as to realize heat shrinkage. shrink processing.

specific Embodiment 3

[0074] It differs from Embodiment 1 mainly in that: in Embodiment 1, the feeding mechanism includes a plurality of feeding racks, and each feeding rack includes a lifting part and an inclined guide rod respectively, and each inclined guide rod is correspondingly arranged on Between the corresponding two V-shaped wheels, correspondingly, a plurality of unloading levers of the unloading mechanism are also correspondingly located between the corresponding two V-shaped wheels. In this embodiment, two inclined guide rods of the loading mechanism and two blanking levers of the unloading mechanism can be provided respectively, and the two inclined guide rods and the two blanking levers are correspondingly located on the two sides of all V-shaped wheels. side to form a two-point support. At this time, in order to improve the stability of the support, the width of the guide rod and the blanking lever can be properly tilted.

[0075] Of course, in other embodiments, three inclined guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com