A tread processing device for solid tires

A processing device and solid tire technology, which is applied in metal processing and other fields, can solve the problems of low processing efficiency, time-consuming and laborious, etc., and achieve the effects of improving processing efficiency, ensuring uniformity, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

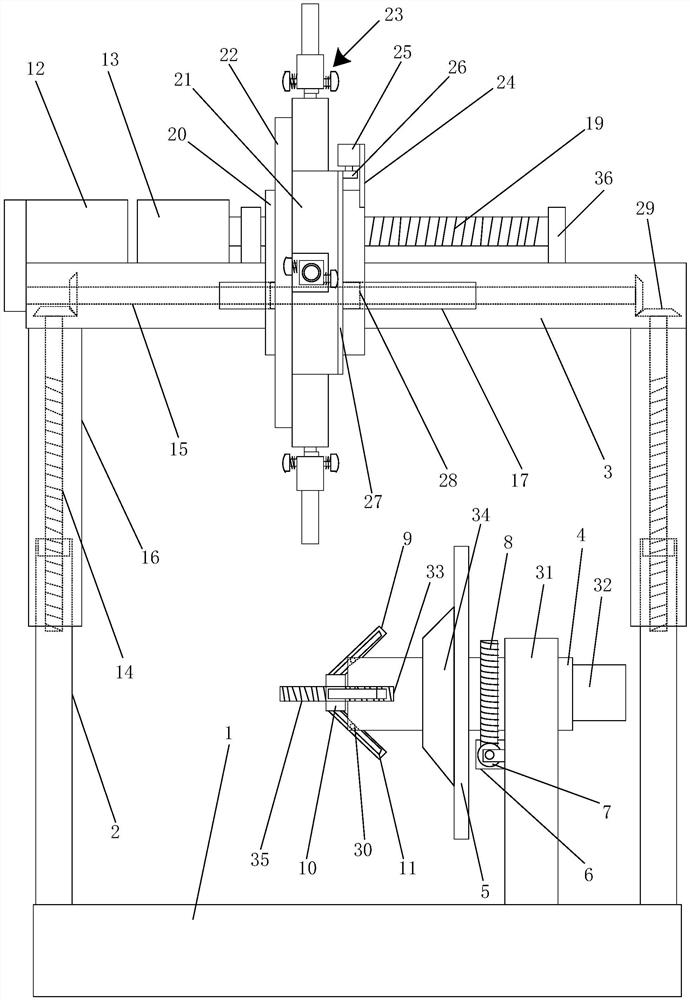

[0021] like Figure 1-3 As shown, the tread processing device for solid tires described in the present invention includes: a device bottom plate 1, two vertical pipe columns 2, a transverse beam 3, a lift drive motor 12, two vertical drive screws 14, a synchronous Rotating shaft 15, transverse driving mechanism, rotary driving mechanism, tire pressing mechanism, tool switching mechanism and each electric tool 23;

[0022] The two vertical pipe columns 2 are respectively vertically fixed and installed in the middle of the left and right sides of the device bottom plate 1, and a lifting drive internal thread is provided at the upper end nozzle of the vertical pipe column 2; the lower ends of the two vertical driving screws 14 The upper ends of the two vertical drive screws 14 are respectively threaded and installed on the left and right ends of the transverse beam 3; the synchronizing shaft 15 is rotated laterally. Installed in the transverse beam 3, and the left and right ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com