Irrigation emitter based on Tesla one-way valve principle and irrigation system thereof

A technology of one-way valves and sprinklers, applied in watering devices, horticultural, botanical equipment and methods, etc., can solve the problems of increasing water head loss along the way, increasing water flow energy consumption, etc., to increase local head loss and increase energy Good effect of consumption and dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

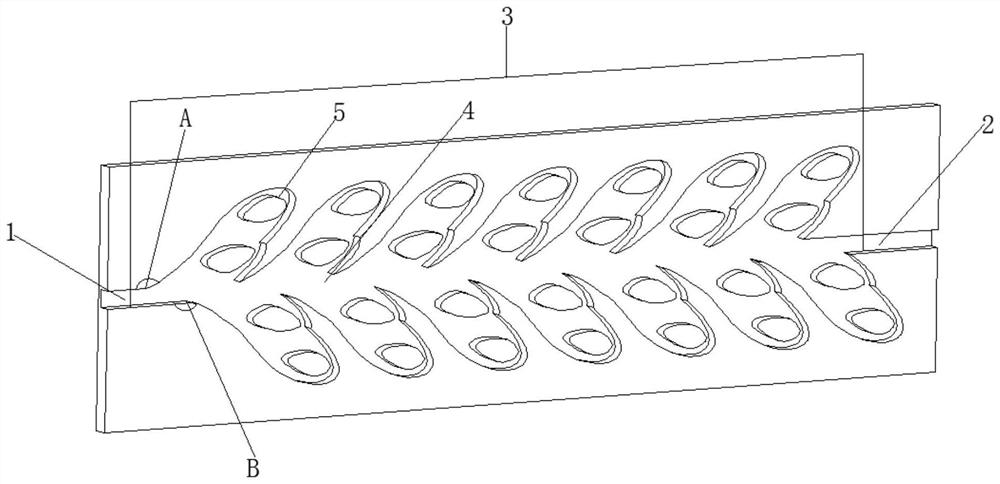

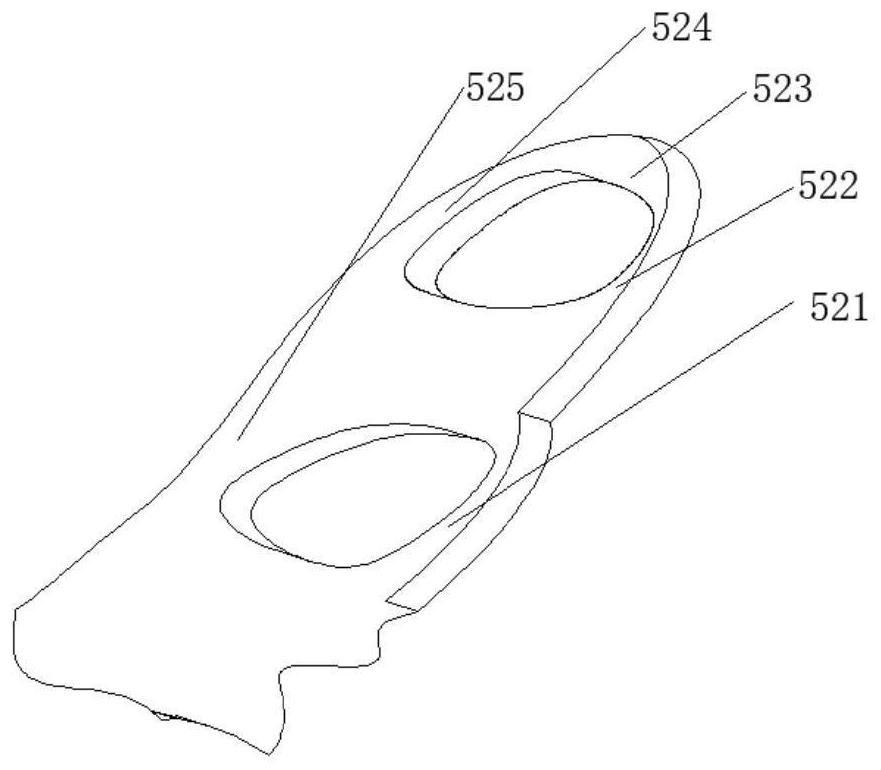

[0042] This embodiment provides an implementation of the emitter based on the Tesla check valve principle. refer to Figure 1 to Figure 3 , figure 1 It is a structural diagram of an emitter based on the Tesla check valve principle provided in the embodiment of the present application; figure 2 yesfigure 1 Structural diagram of the middle runner unit; image 3 It is the structural diagram of the capillary in 2. Such as Figure 1 to Figure 3 As shown, the emitter based on the Tesla check valve principle includes: a water inlet pipe 1, a water outlet pipe 2 and a flow channel device 3, and the flow channel device 3 includes:

[0043] Main flow pipe 4, located in the middle of the flow channel device 3;

[0044] Several flow channel units 5 are evenly connected in series and arranged oppositely on the upper and lower sides of the main flow pipe 4;

[0045] The channel unit 5 is sequentially provided with several obstacles 51 from bottom to top, and the obstacles 51 divide t...

Embodiment 2

[0071] This embodiment provides a specific implementation of the irrigation system, including the irrigator based on the principle of the Tesla check valve in Example 1, and the irrigator based on the principle of the Tesla check valve is embedded in the guide according to the requirements of the planting distance of the crops. The water hollow hose controls the central control system, and the water is sent to the filter system through the pressure pump for filtration, and finally sent to the water guide hollow hose, through the emitter based on the Tesla check valve principle in the water guide hollow hose Reduce the flow rate of water to achieve the purpose of drip irrigation for crops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com