Oil level checking device and method

The technology of a calibration device and calibration method is applied in the field of oil level calibration, which can solve the problems of large oil level calibration error, equipment damage, and high cost of infrared temperature measurement equipment, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

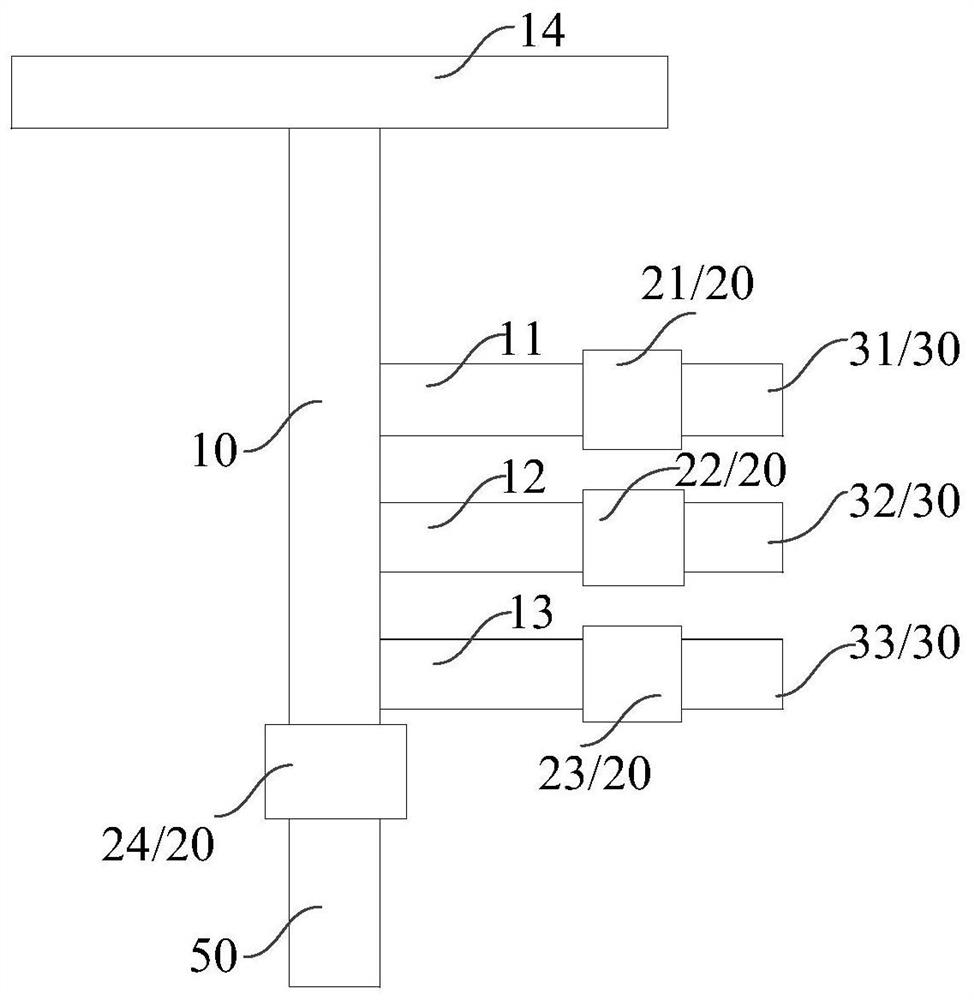

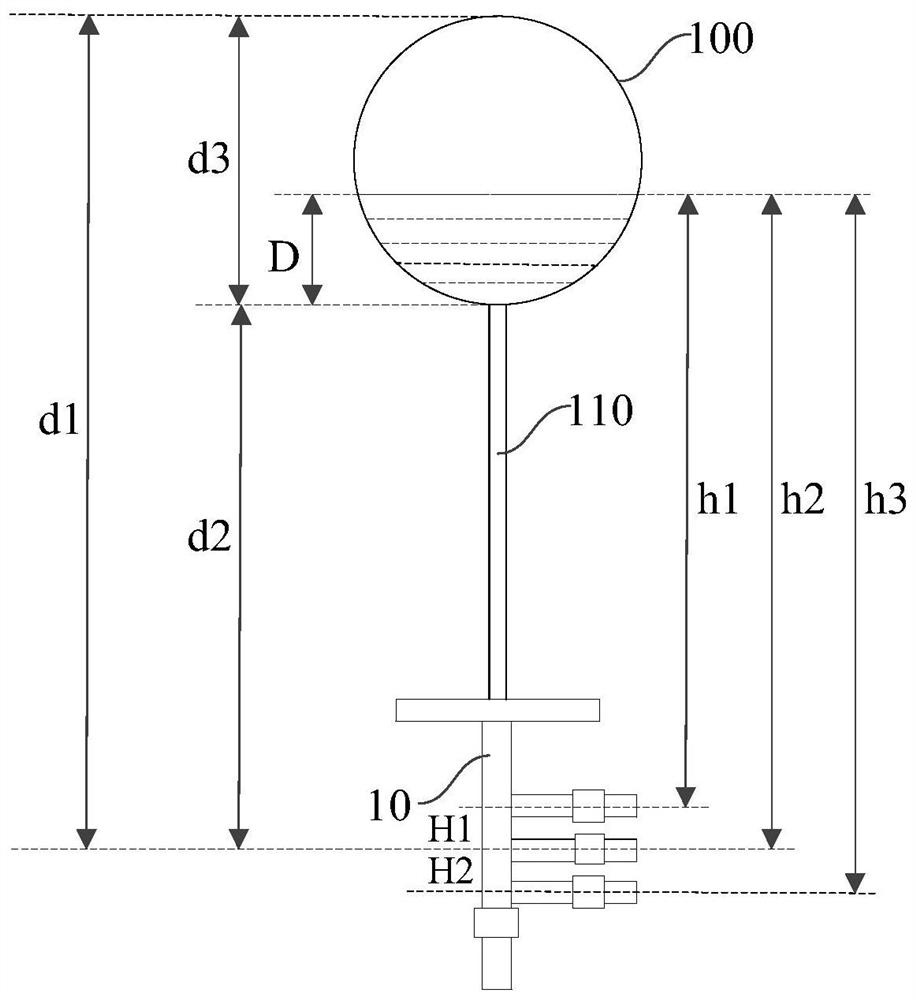

[0031] figure 1 It is a schematic structural diagram of an oil level calibration device provided in Embodiment 1 of the present invention, figure 2 It is a structural block diagram of a partial structure of an oil level verification device provided in Embodiment 1 of the present invention. This embodiment is applicable to the verification of transformer oil level, etc., combined figure 1 with figure 2 , the oil level verification device includes: a main body 10, a plurality of valves 20, a plurality of pressure sensors 30 corresponding to the plurality of valves, and a control module 40.

[0032] Wherein, the top of the main body 10 communicates with the oil conservator through the oil discharge pipe 110 of the oil conservator 100; each valve 20 is installed at different height positions of the main body 10; The position height of 10 is the same as that of the corresponding valve 20, and the distance between each pressure sensor 30 is the same, and the pressure sensor 30 i...

Embodiment 2

[0049] Figure 4 It is a flow chart of an oil level verification method provided in Embodiment 2 of the present invention. The oil level verification method is executed by the control module in the oil level verification device described in any embodiment of the present invention, and specifically includes the following steps:

[0050] S110. Receive the pressure of the oil in the oil conservator collected by the pressure sensor.

[0051] Wherein, the pressure sensor in the oil level calibration device includes a first pressure sensor, a second pressure sensor and a third pressure sensor, the position height of the first pressure sensor in the main body is higher than that of the second pressure sensor, and the position height of the second pressure sensor is higher than that of the second pressure sensor. When the height of the main body is higher than that of the third pressure sensor, the pressure of the oil collected by the first pressure sensor is the first pressure P 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com