Cremator flue gas pipeline system

A technology for cremation furnaces and flue gas pipes, which is applied in the direction of exhaust gas exhaust devices, climate sustainability, and reduction of greenhouse gases. problems, to achieve the effect of improving heat utilization efficiency, low construction cost, and reasonable overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

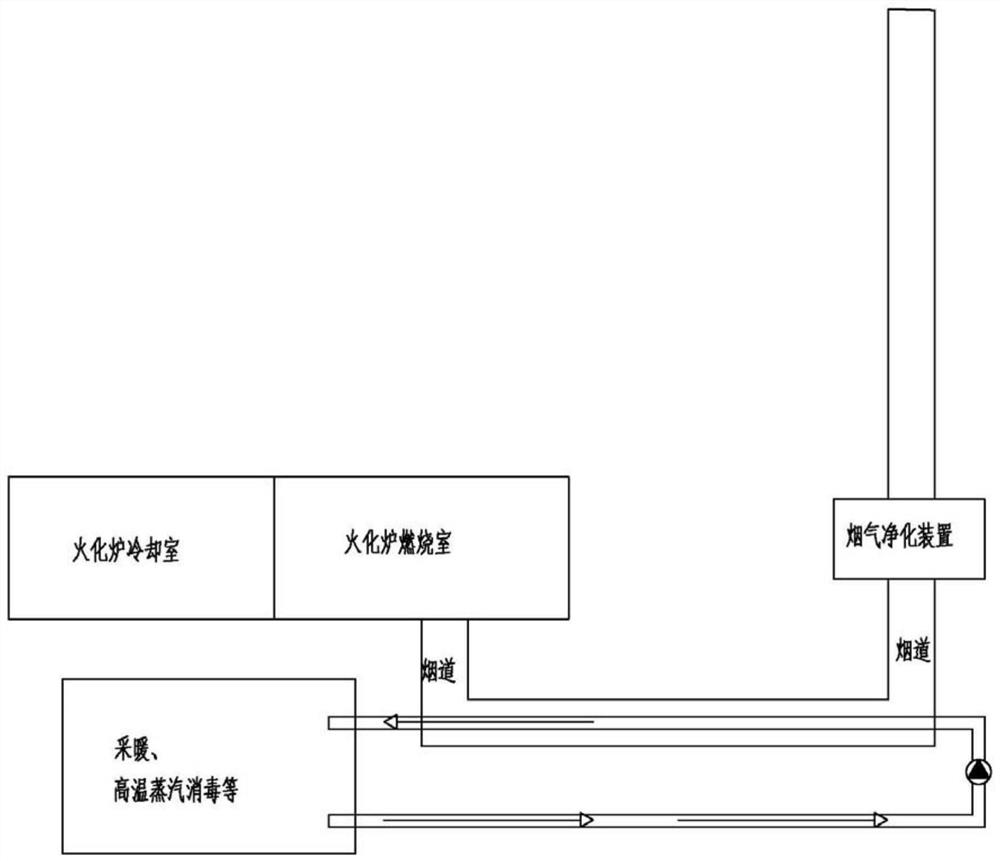

[0038] Such as figure 2 As shown, a flue gas pipeline system of a cremation furnace includes a flue gas transfer pipe 1 and a flue gas discharge pipe 2. At the entrance of the gas discharge pipe 2, a flue gas purification device 9 is arranged on the flue gas discharge pipe 2; part of the pipe section of the flue gas transfer pipe is buried underground, which is recorded as a horizontal flue;

[0039] The horizontal flue is sequentially divided into a front bend, an integrated flue 101 and a rear bend, wherein the integrated flue is the main part of the horizontal flue (the length ratio is usually more than 70%);

[0040] The feature of this embodiment is that it also includes a heat exchange medium circulation pipeline and a heat exchanger 7; the heat exchanger 7 is a well-known and mature product in the field of heat supply technology, and can be selected according to needs.

[0041] The heat exchange medium circulation pipeline includes an integrated heat exchange pipe 3 a...

Embodiment 2

[0053] Based on the above embodiments, a spare horizontal pipe can also be fixedly arranged on the side of the integrated flue 101 and equipped with a corresponding pipe joint assembly.

[0054] In this way, when it is necessary to repair the integrated flue and the integrated heat exchange tube, it can be temporarily switched to the standby horizontal tube to continue transporting the flue gas, so that the machine will not be shut down for a long time. In addition, the pipe diameter of the spare horizontal pipe can be consistent with the pipe diameters of the above-mentioned front-end bend pipe and rear-end bend pipe, which is convenient for quick and reliable sealing and docking.

Embodiment 3

[0056] With reference to the principle of any of the above embodiments, a parallel system of multiple cremation furnace heat exchange systems can also be formed, that is, there are multiple cremation furnaces, and correspondingly, there are multiple groups of flue gas transfer pipes, flue gas discharge pipes, and heat exchange medium circulation. Pipelines; the corresponding hot water collection tanks on each group of heat exchange medium circulation pipelines are connected to each other, or a unified hot water collection tank and heat exchanger are arranged on multiple sets of heat exchange medium circulation pipelines.

[0057] In this way, the intensive management of the entire site can be realized, and the efficiency of thermal energy utilization can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com