Comprehensive earth excavation method for large-scale cover-excavation top-down T-shaped transfer subway station

A technology for subway station, cover and excavation reverse work, applied in excavation, water conservancy projects, artificial islands, etc., can solve the problems of unstable excavation, high cost, low excavation efficiency, etc., to shorten the construction period of earthwork, improve efficiency, and speed up excavation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features of the present invention and other relevant features are described in further detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

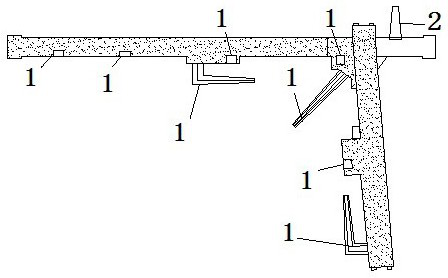

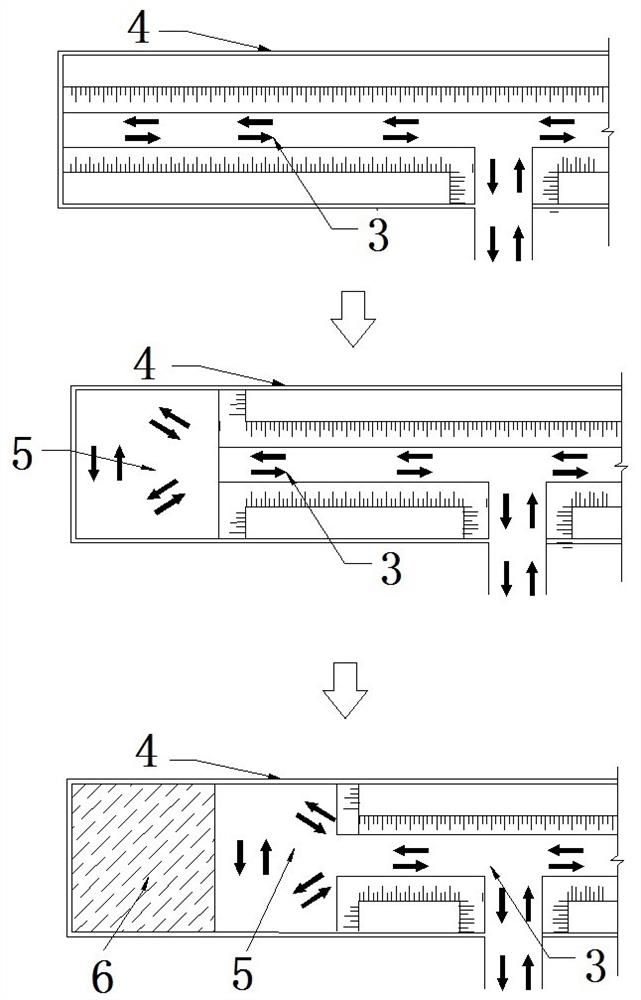

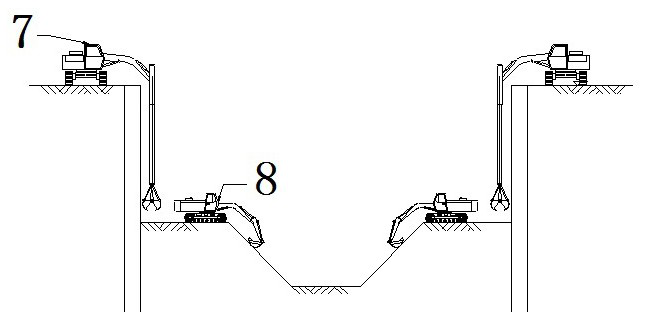

[0020] Such as Figure 1-4 , the marks in the figure are: excavation opening 1, spare excavation opening 2, excavation passage 3, underground diaphragm wall 4, earthwork excavation area 5, floor pouring area 6, long-arm excavator 7, earth excavation machine 8, soil transportation vehicle9.

[0021] Example: such as figure 1 , 2 , 3, and 4, this embodiment specifically relates to a comprehensive earthwork excavation method for a large-scale cover-excavation T-shaped interchange subway station, which is especially suitable for complex underground conditions, large excavation volume of foundation pits, and small excavation area of foundation pits , and foundation pits with deep excavation depths and urban underground rail projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com