Container truck parking alignment, smashing prevention and lifting prevention device for tire crane

A tire crane, anti-smashing and anti-smash technology, which is applied in the direction of safety devices, trolley cranes, cranes, etc., can solve problems such as difficult operation, hidden safety hazards, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

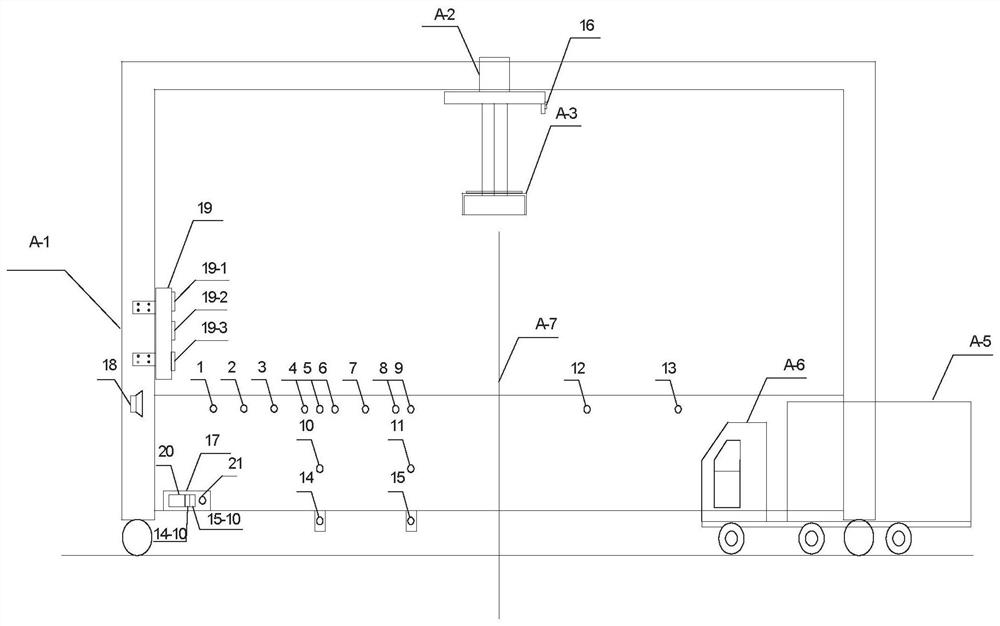

[0054] As shown in the figure, the present invention includes an alarm reset button 21, a plurality of distance measuring sensors arranged laterally on the upper part of the side beam of the tire crane, a distance measuring sensor 16 arranged on the tire crane trolley, the alarm reset button 21 and the control part 20. The detection signal input port is connected, and the control signal output port of the control part 20 is respectively connected with the parking alignment indicating module 19 and the sound and light alarm 18 arranged on the side column of the tire crane;

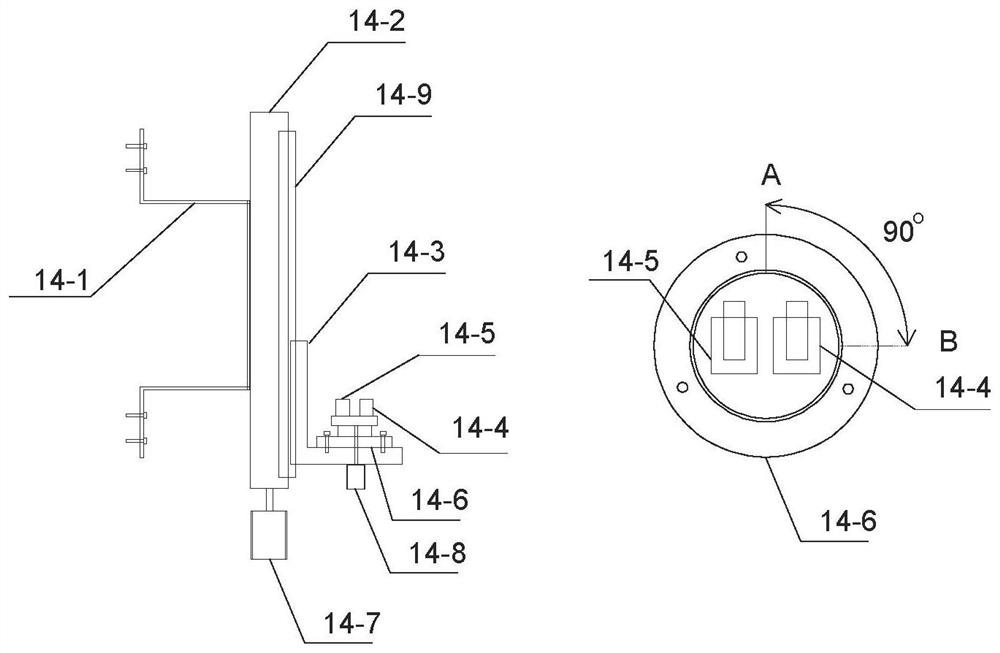

[0055] It also includes a first collection truck separation detection module 14 and a second collection truck separation detection module 15. The first collection truck separation detection module 14 and the second collection truck separation detection module 15 are arranged at the front lower part of the side beam of the tire crane. The separation detection module 14 is arranged on the front side of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com