Section steel machining device with hidden adjusting mechanism

A technology for regulating mechanisms and processing devices, which is applied in the direction of quenching devices, manufacturing tools, conveyor objects, etc., can solve the problems of single installation location and processing method, inability to extract water treatment and recovery, and low resource recovery utilization rate, etc., to achieve The operation mode is simple and diverse, the lifting angle adjustment range, and the effect of stable structural position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

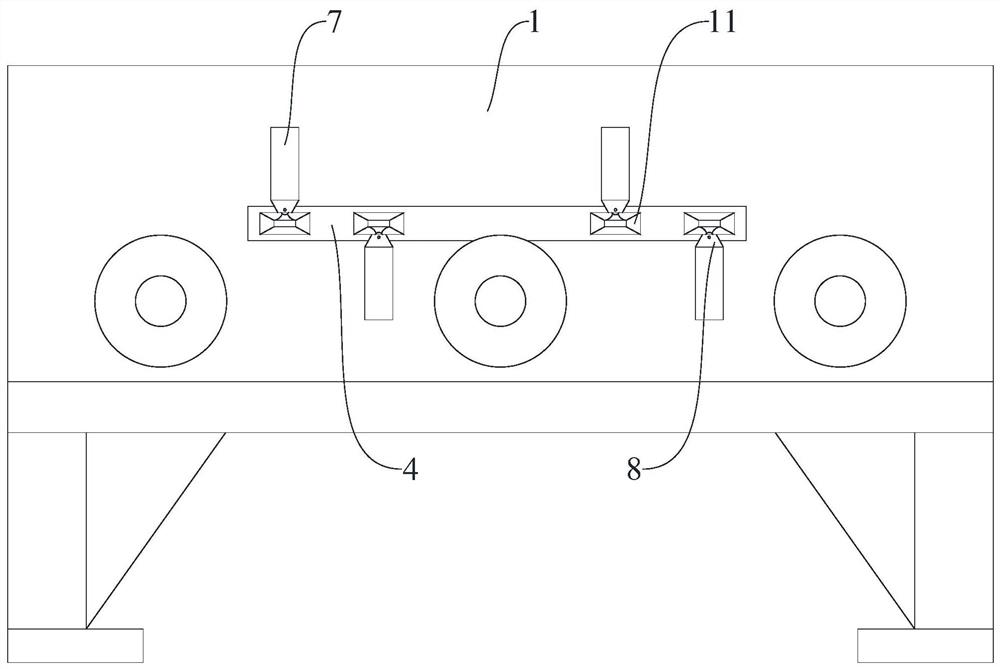

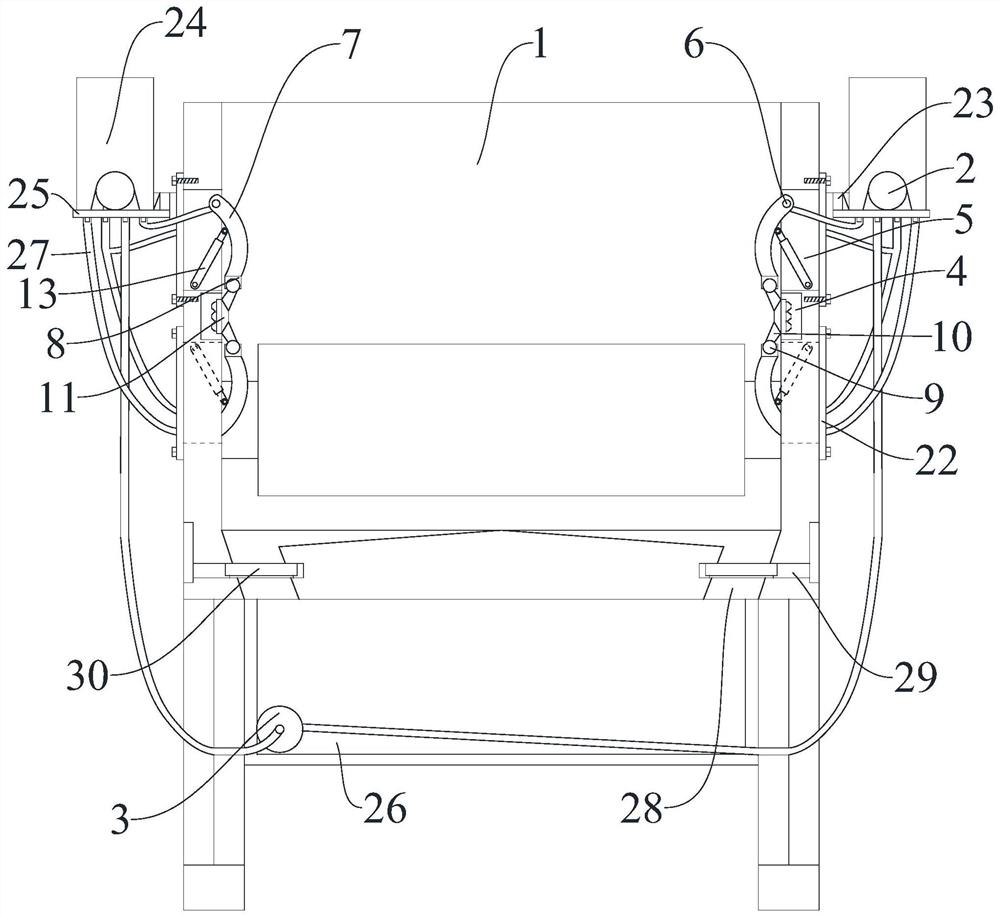

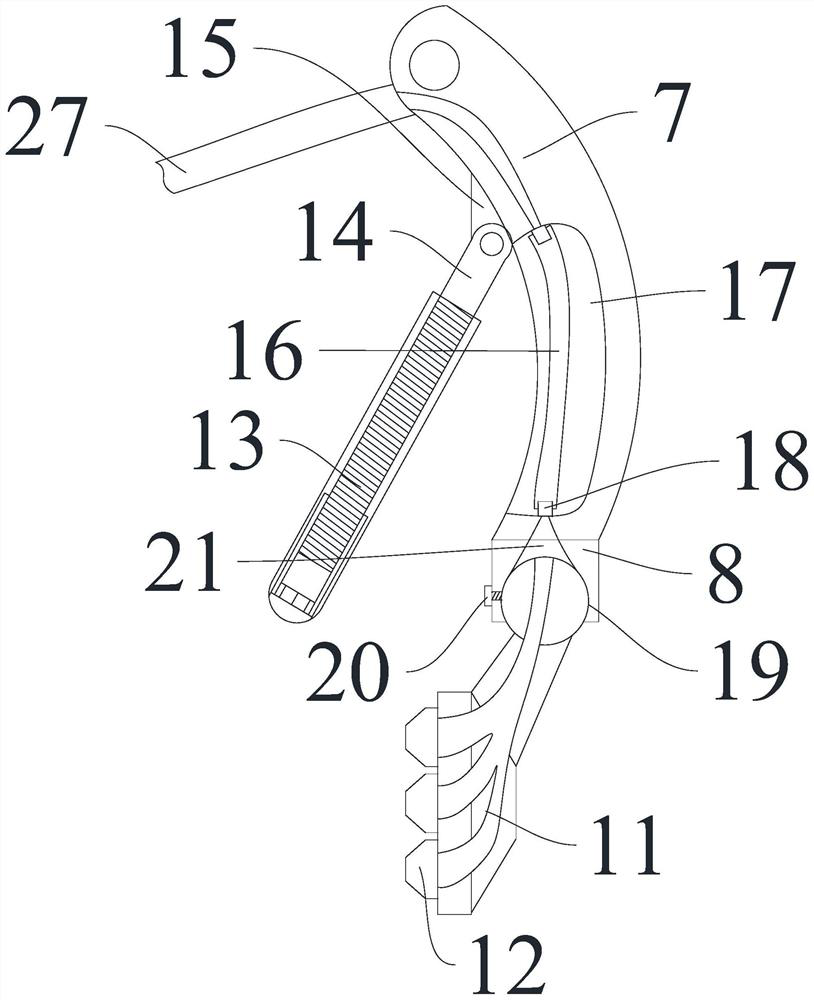

[0027] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0028] figure 1 , figure 2 and image 3 A profile steel processing device with a hidden adjustment mechanism is shown, including the main frame 1 with built-in horizontal conveying rollers, the high-pressure air pump 2 and the electric liquid pump 3, and the high-pressure air pump 2 and the electric liquid pump 3 are purchased directly from the market , through the infrared temperature switch to automatically control the opening and closing, when it is detected that the high-temperature profile is approaching, the control will start, and it will be closed after leaving, first start the blowing and water injection, and then start the suction and return water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com