Operating personnel fatigue detection server and system

A technology for worker and fatigue detection, applied to sensors, evaluation of respiratory organs, diagnostic recording/measurement, etc., to achieve the effect of overcoming strong subjectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

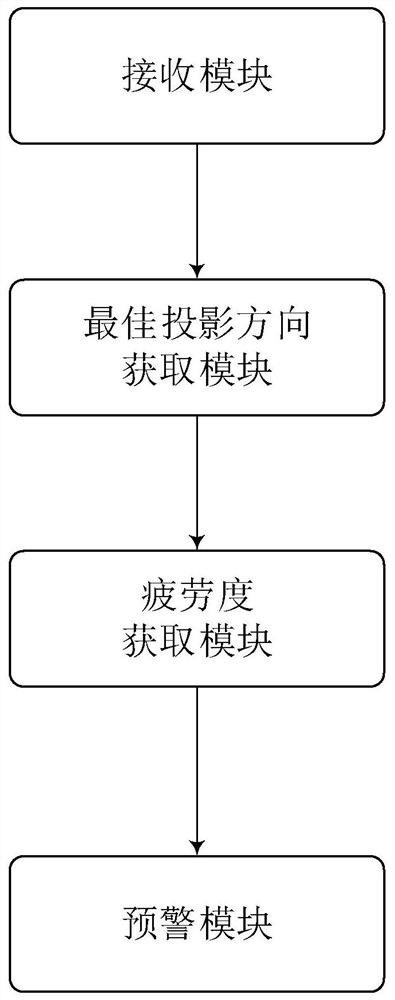

[0070] figure 1 It is a functional block diagram of an operator fatigue detection server involved in the present invention;

[0071] Such as figure 1 As shown, this embodiment 1 provides a worker fatigue detection server, which is characterized in that it includes: a receiving module, which receives the change data of human physiological information; an optimal projection direction acquisition module, which acquires a one-dimensional space according to the change data of human physiological information The best projection direction of the dimensional space; the fatigue degree acquisition module predicts the fatigue degree of the operator according to the best projection direction of the one-dimensional space; and the early warning module provides early warning for the operator and the operating equipment according to the fatigue degree of the operator.

[0072] In this embodiment, through this embodiment, the fatigue prediction and early warning of the operators are realized,...

Embodiment 2

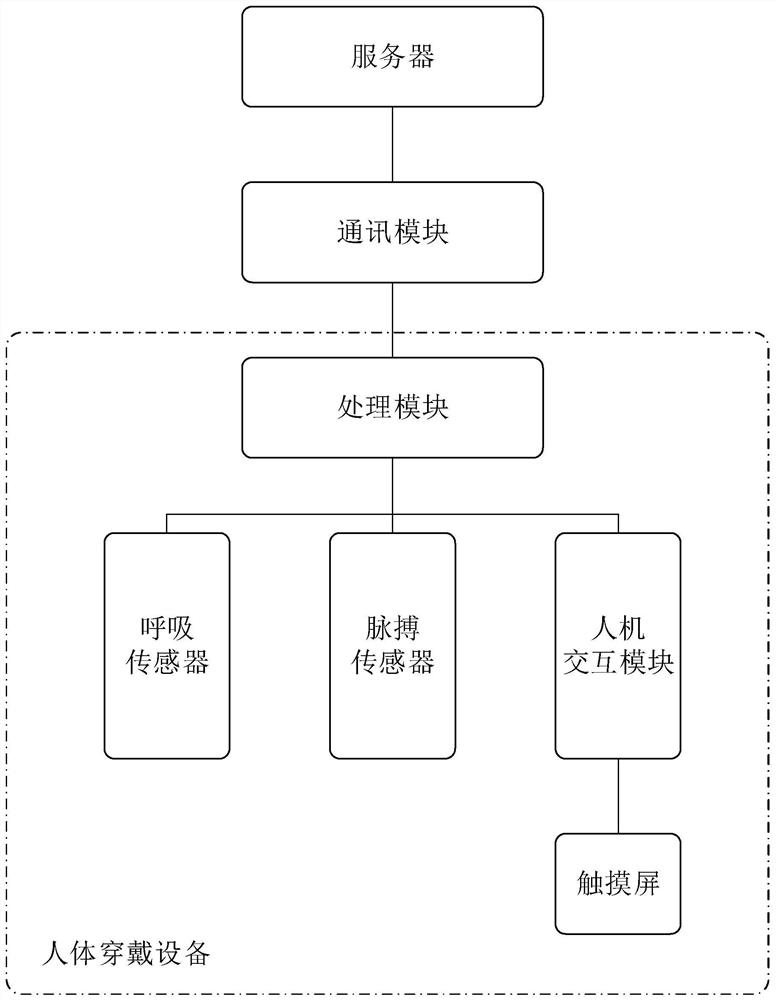

[0117] figure 2 It is a functional block diagram of the operator fatigue detection system involved in the present invention;

[0118] Such as figure 2 As shown, Embodiment 2 provides an operator fatigue detection system, which is characterized in that it includes: the operator fatigue detection server as described in Embodiment 1, and a human body wearable device connected to the operator fatigue detection server;

[0119] The human body wearable device is suitable for collecting human physiological information change data, that is, human respiratory cycle data, human pulse cycle data and human fatigue performance scale data, and sending them to the receiving module.

[0120] In this embodiment, the operator fatigue detection server is used to predict the fatigue degree of the operator, and give an early warning to the operator and the operating equipment according to the fatigue degree of the operator.

[0121] Specifically, the human body wearable device includes:

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com