Power battery isolation placement box

A power battery and placing box technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of difficult dissipation of battery heat, easy burnout and damage of lines, and difficult disassembly of the isolation box, so as to facilitate maintenance and repair. The effect of ensuring the operating environment and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

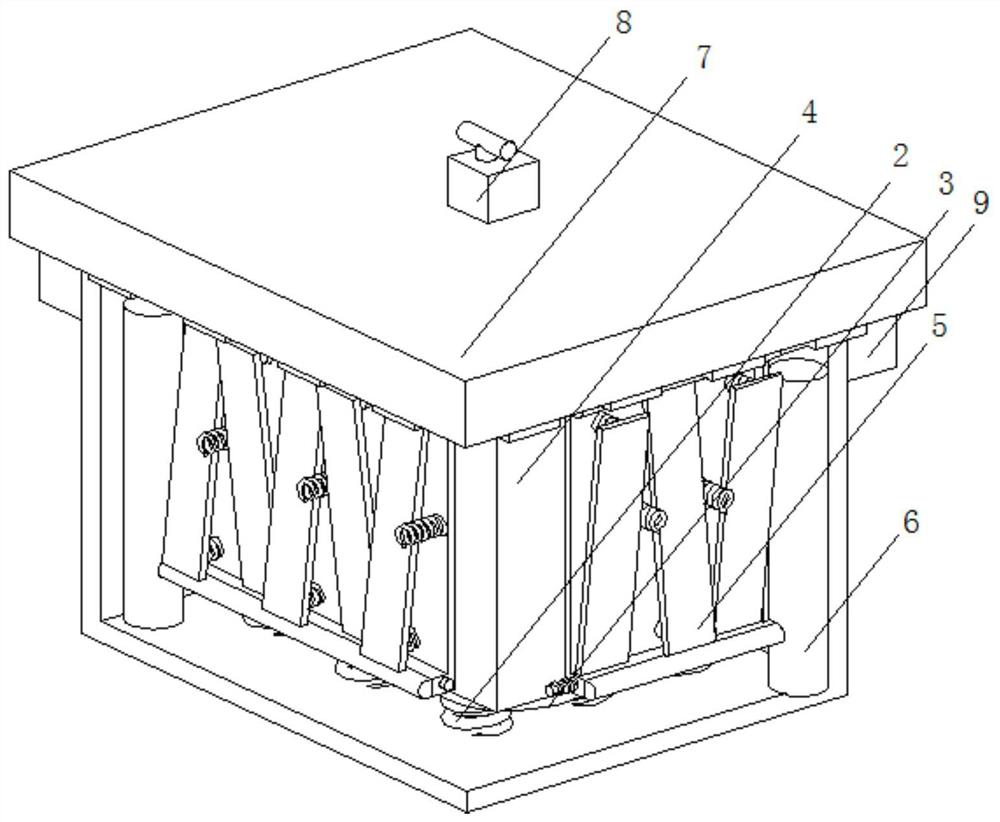

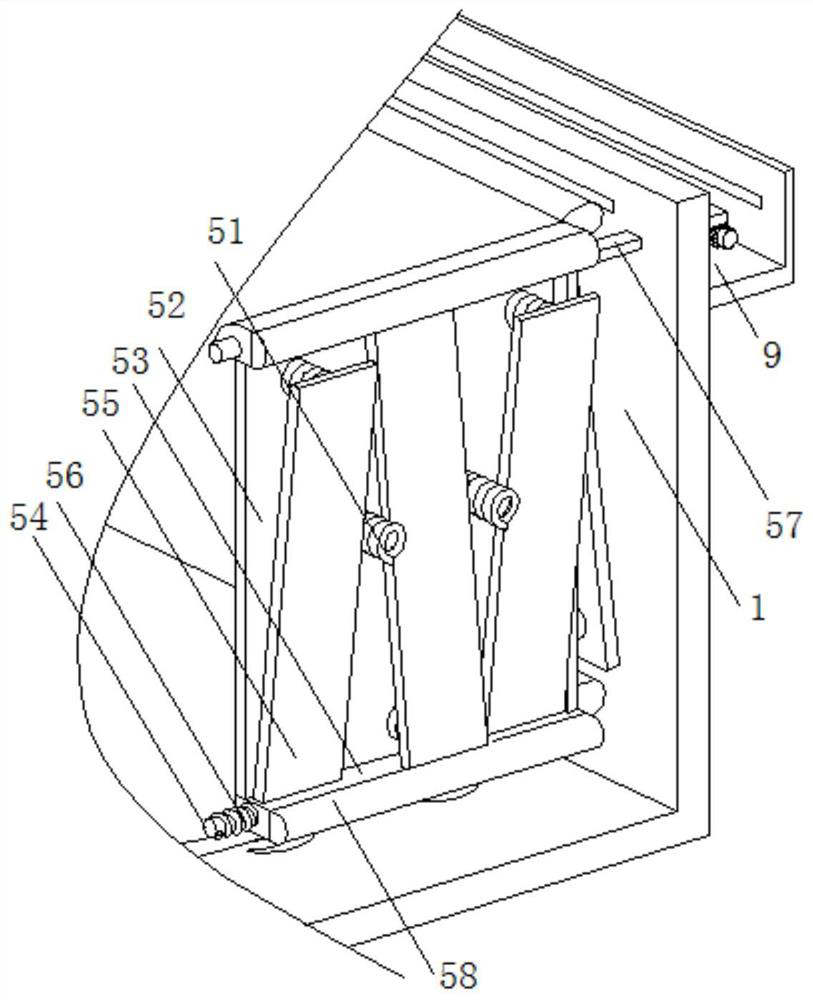

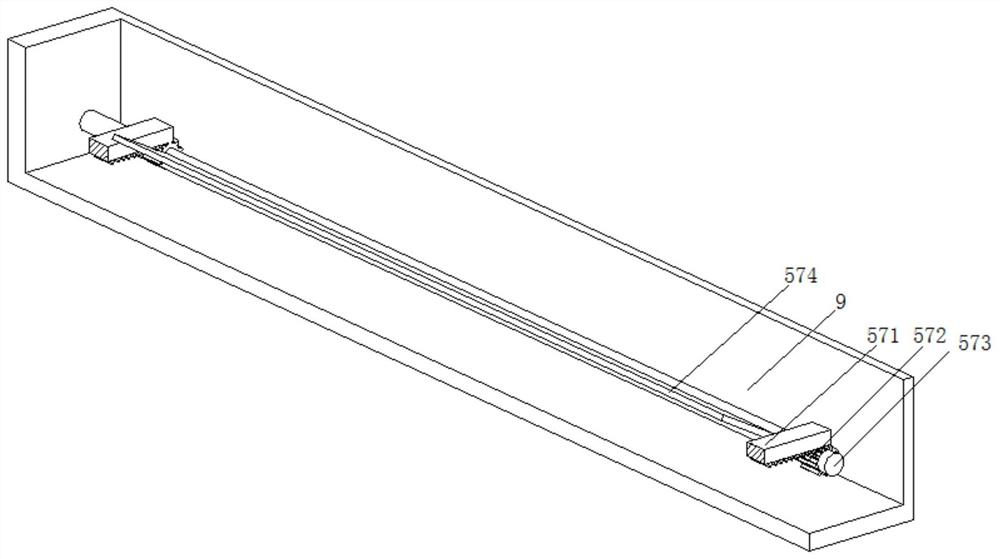

[0031] An isolated storage box for a power battery, such as Figure 1-Figure 5 As shown, it includes a box body 1, the bottom of the box body 1 is welded with a buffer spring 2, the top of the buffer spring 2 is welded with a bottom plate 3, the top of the bottom plate 3 is movably connected to a battery body 4, and the surface of the battery body 4 is provided with a buffer cooling mechanism 5. The inside of the box body 1 is fixedly connected with the protective side column 6, the top of the box body 1 is clamped with a top cover 7, the inside of the top cover 7 is provided with a snap-in mechanism 8, and the surface of the box body 1 is welded with a side box 9, The bottom of the top cover 7 is provided with a buffer plate.

[0032] After the top cover 7 is clipped and fixed with the box body 1, the buffer plate at the bottom contacts with the top of the battery body 4, and shock-absorbing protection is performed on the bottom, and the buffer spring 2, the bottom plate 3 an...

Embodiment 2

[0044] Such as Figure 6-7 As shown, on the basis of Embodiment 1, in this embodiment, the clamping mechanism 8 includes a sliding seat 81 and a starting device 85, the surface of the sliding seat 81 is slidably connected with the inner wall of the top cover 7, and the bottom of the sliding seat 81 is welded Folding block 82 is arranged, and the internal screw thread of slide seat 81 is connected with threaded rod 83, and the left end of threaded rod 83 is welded with bevel gear-84, and the surface of threaded rod 83 is connected with the interior of top cover 7 by rotation, and folded block 82 The surface of the surface is slidably connected with the inner wall of the top cover 7.

[0045] By setting the clamping mechanism 8, the interaction between the various internal structures can be used to achieve the effect of easy installation and disassembly of the box body 1 as a whole, and at the same time, the internal self-locking function can be used to stably fix the box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com