Automatic split charging and extracting system for air sampling carbon tubes

An extraction system and air sampling technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of easy scattering of carbon particles, reducing the accuracy of test results, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

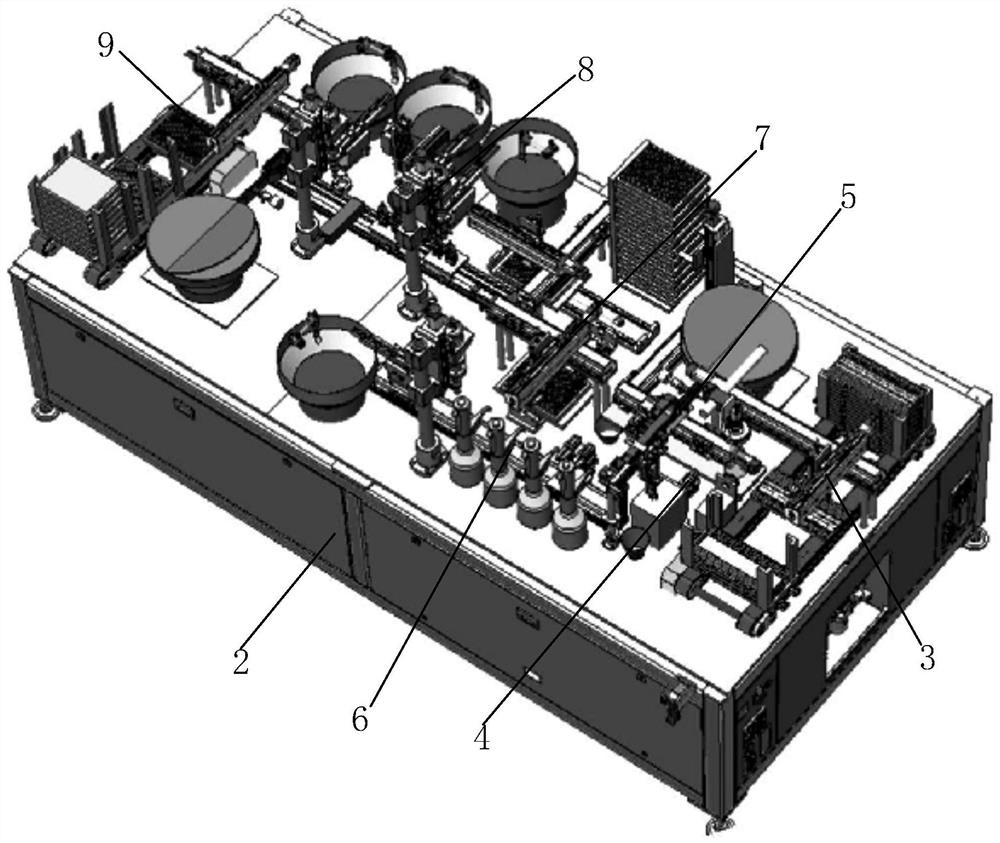

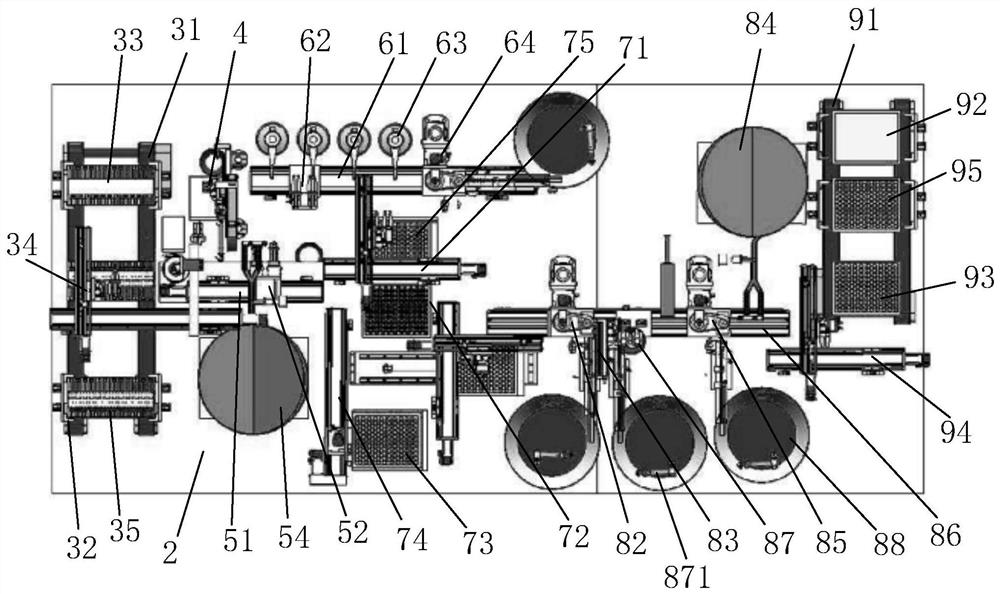

[0080] A kind of air sampling carbon tube automatic packing extraction system, such as Figure 2 to Figure 12 As shown, it includes: frame 2; the carbon tube feeding device 3 carried on the frame 2; the carbon tube breaking device 4 carried on the frame 2; the transfer device 5 carried on the frame 2; Adding and transferring device 6; static device 7 carried on frame 2; pipetting device 8 carried on frame 2; and receiving and storing device 9 carried on frame 2 for storing the detection bottle with capping completed .

[0081] Specifically, the carbon tube feeding device 3 includes: a feeding conveyor belt 31 for forwardly conveying the first loading trays 35 one by one, a first full tray warehouse 32 arranged on one side of the feeding conveyor belt 31, The first empty bin 33 on the other side of the feeding conveyor belt 31 and the carbon tube loading manipulator 34 for grabbing the carbon tubes one by one, the first loading tray 35 is loaded with several carbon tubes.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com