Automobile supercharged engine capable of avoiding hysteresis control starting and fully utilizing fuel

A supercharged engine, hysteresis control technology, applied in combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problems of slow compressor rotation, turbo lag, and slow turbine rotation speed, to increase the area, avoid Hysteresis, the effect of reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

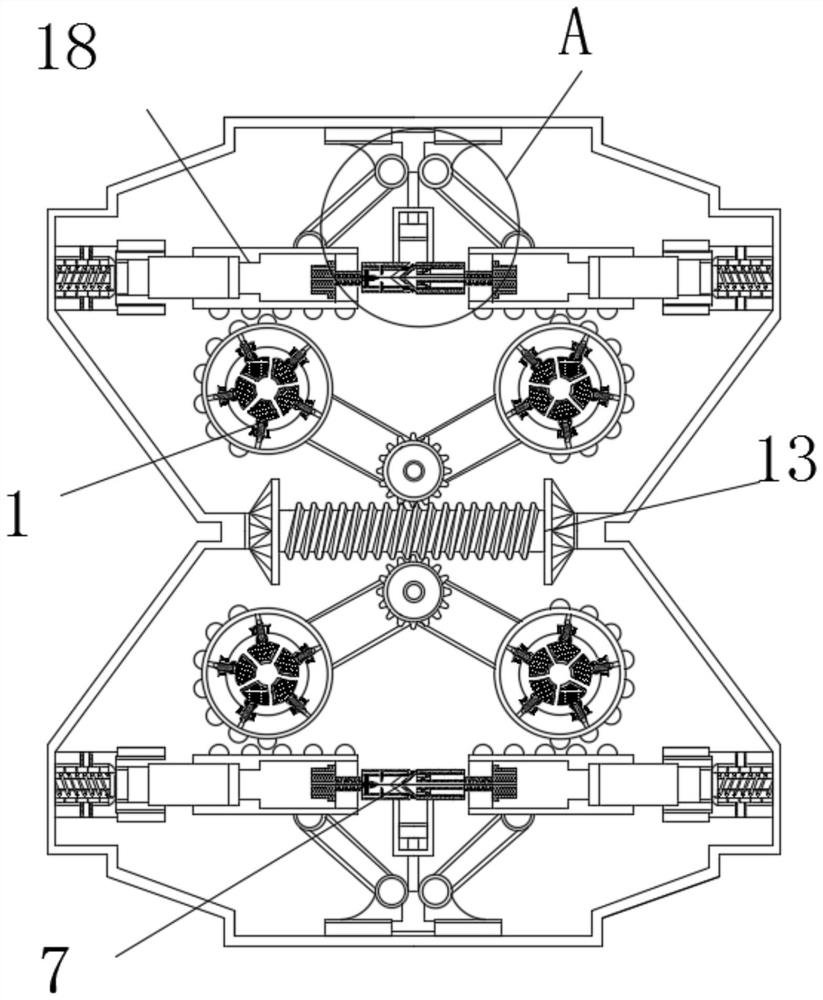

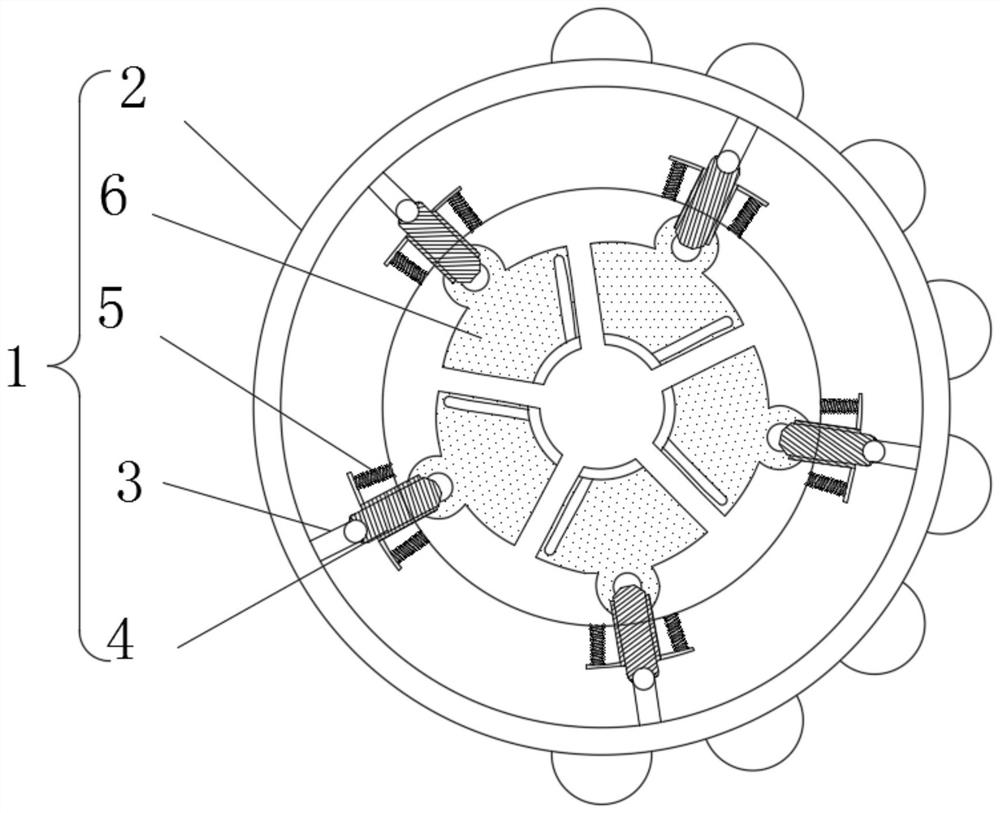

[0024] see figure 1 and 3 , an automobile supercharged engine that avoids hysteresis control and fully utilizes fuel, including a wind control mechanism 1 and a push mechanism 7, the wind control mechanism 1 includes an incomplete gear 2, and the inside of the incomplete gear 2 is fixedly connected with a guide rod 3, The side of the guide rod 3 away from the incomplete gear 2 is fixedly connected with a horizontal plate 4 , the side of the horizontal plate 4 away from the guide rod 3 is fixedly connected with a compression spring 5 , and the surface of the horizontal plate 4 is fixedly connected with an arc plate 6 .

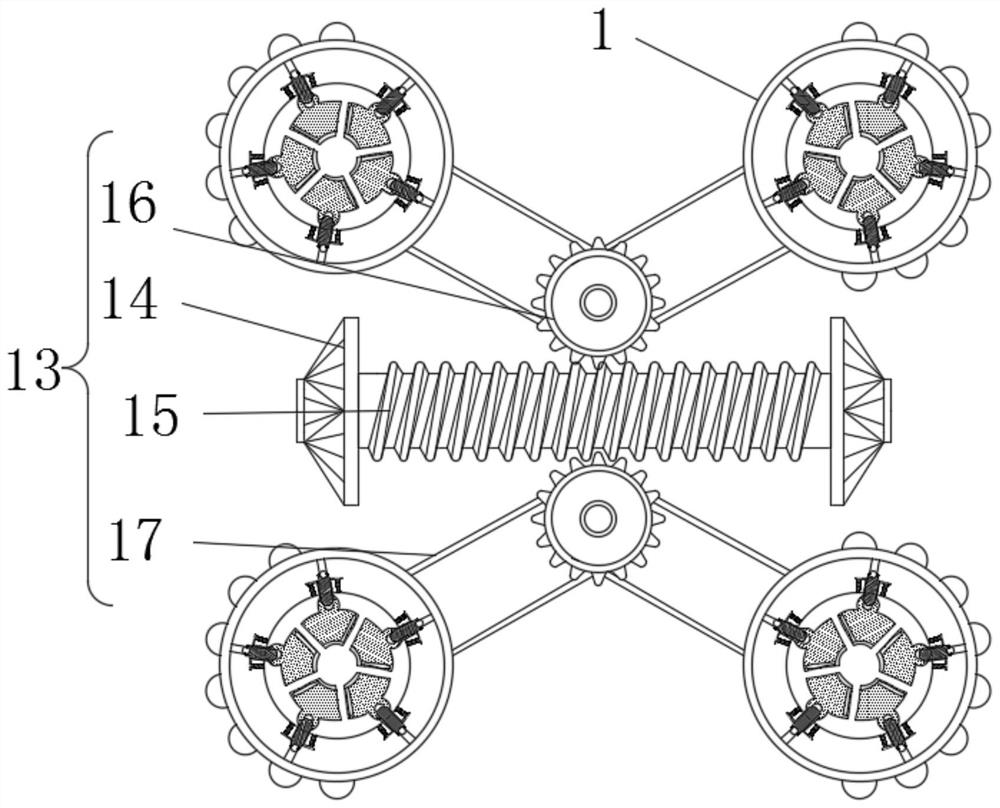

[0025] Further, the transmission mechanism 13 includes a worm gear 14 , the surface of the worm gear 14 is fixedly connected with a threaded column 15 , the upper and lower sides of the threaded column 15 are movably connected with a gear 16 , and the surface of the gear 16 is sleeved with a belt 17 .

[0026] Through threaded column 15, gear 16 cooperates wit...

Embodiment 2

[0028] see figure 1 and 4 , an automobile supercharged engine that avoids hysteresis control and fully utilizes fuel, including a wind control mechanism 1 and a push mechanism 7, the wind control mechanism 1 includes an incomplete gear 2, and the inside of the incomplete gear 2 is fixedly connected with a guide rod 3, The side of the guide rod 3 away from the incomplete gear 2 is fixedly connected with a horizontal plate 4 , the side of the horizontal plate 4 away from the guide rod 3 is fixedly connected with a compression spring 5 , and the surface of the horizontal plate 4 is fixedly connected with an arc plate 6 .

[0029] Further, the periodic mechanism 18 includes a rack plate 19, the surface of the rack plate 19 is fixedly connected with a top block 20, and the side of the top block 20 away from the rack plate 19 is fixedly connected with a return spring 21, and the rack plate 19 is away from the top block 20 One side is socketed with cross bar 22.

[0030] The rack p...

Embodiment 3

[0032] see Figure 1-5 , an automobile supercharged engine that avoids hysteresis control and fully utilizes fuel, including a wind control mechanism 1 and a push mechanism 7, the wind control mechanism 1 includes an incomplete gear 2, and the inside of the incomplete gear 2 is fixedly connected with a guide rod 3, The side of the guide rod 3 away from the incomplete gear 2 is fixedly connected with a horizontal plate 4, the side of the horizontal plate 4 away from the guide rod 3 is fixedly connected with a compression spring 5, the surface of the horizontal plate 4 is fixedly connected with an arc plate 6, and the wind control mechanism The surface activity of 1 is movably connected with periodic mechanism 18.

[0033] The periodic mechanism 18 includes a rack plate 19, the surface of the rack plate 19 is fixedly connected with a top block 20, the side of the top block 20 away from the rack plate 19 is fixedly connected with a return spring 21, and the side of the rack plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com