Module building integrated connecting device and mounting method

A connection device and module connection technology, applied in the direction of buildings, building components, building reinforcements, etc., can solve the problems of high welding requirements, prolonged construction period, cumbersome procedures, etc., to improve the force transmission effect, simplify the installation method, and ensure the connection. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

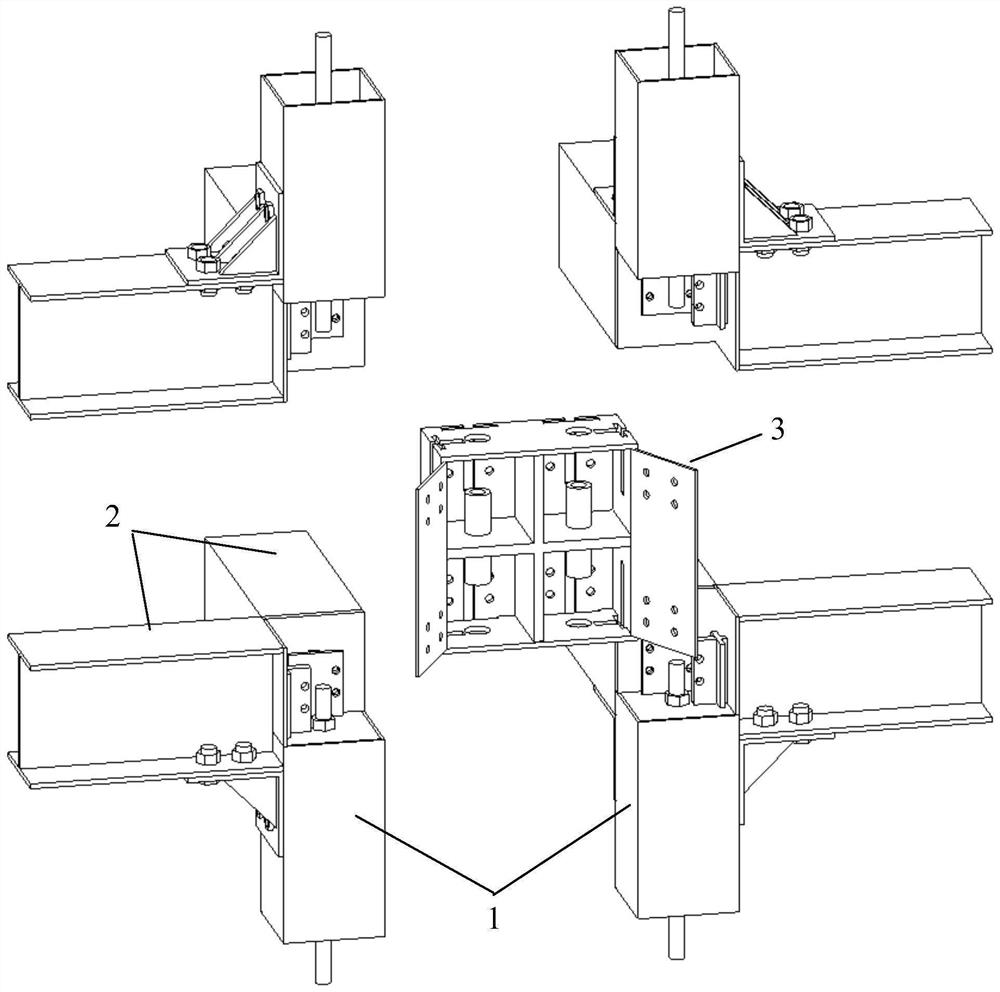

[0062] Such as Figure 11 As shown, it is a structural schematic diagram of the modular column at the corner, the modular beam, and the upper and lower core connection mechanisms in a connected state.

Embodiment 2

[0064] Such as Figure 12 As shown, it is a structural schematic diagram of the connection between the module column on the top floor, the beam module, and the core connection mechanism located in the middle of the two beam modules.

Embodiment 3

[0066] Such as Figure 13 As shown, it is a structural schematic diagram of the connection between the bottom module column and the beam module, and the core connection mechanism located in the middle of the two beam modules.

[0067] Such as Figure 14 As shown, at this time, the bottom of the core connection mechanism is provided with a connection plate, and the two ends of the connection plate are respectively fixedly connected with the bottoms of the beam modules on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com