Axial flow fan device

An axial flow fan and fan technology, which is applied to pump devices, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of large space requirements, large size, large load, etc. Reduced space requirements, reduced vibration and noise levels, reduced load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the patent embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the patent embodiments of the present invention.

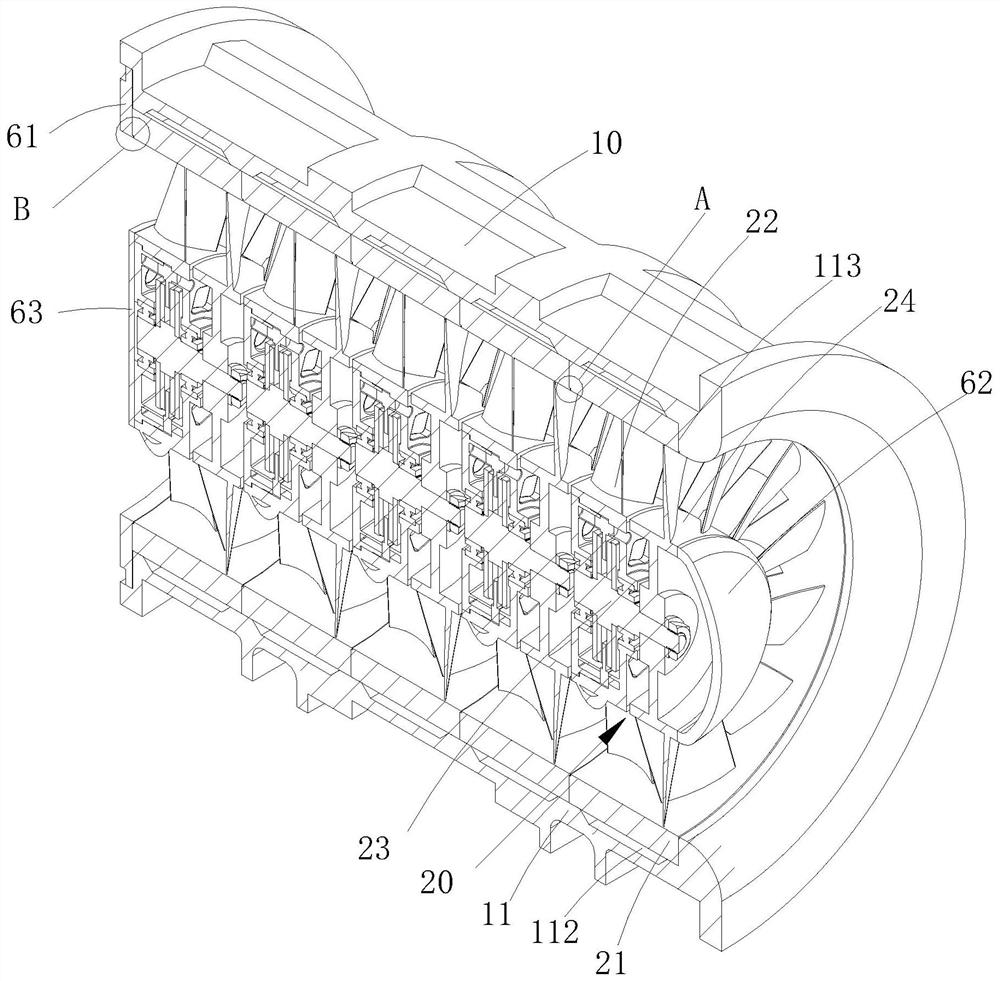

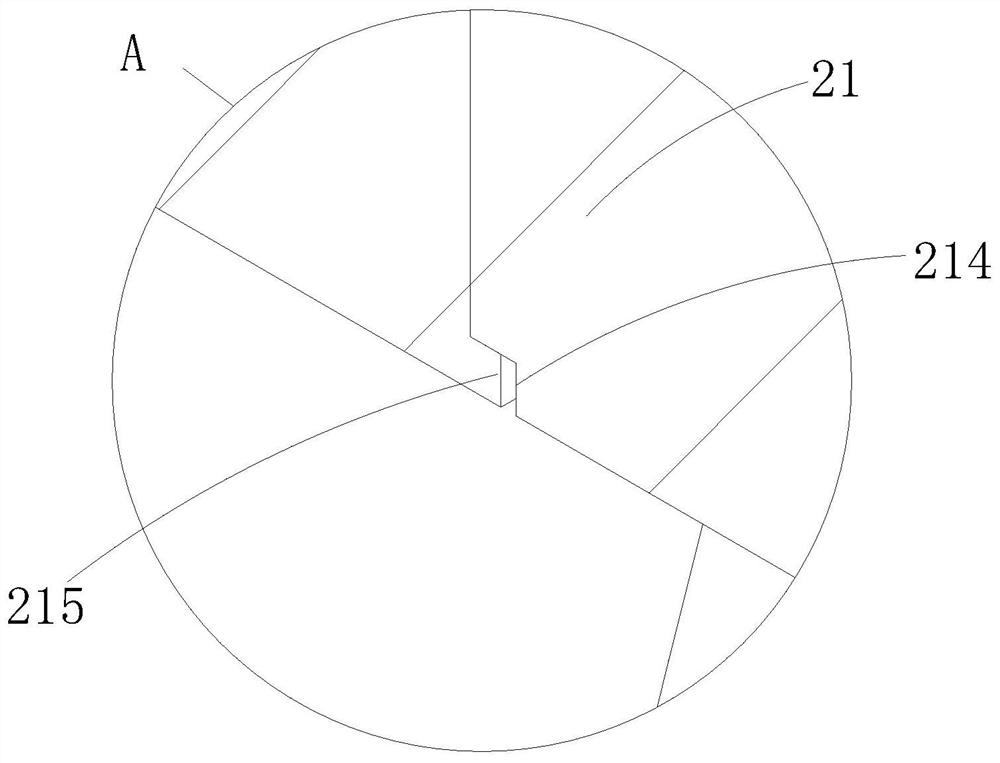

[0038] figure 1 Shown is an axial fan consisting of five separate fan modules connected in series, with the five fan modules located within the same fan housing. figure 2 A cross-sectional view along the axis A-A of Figures is shown, and shows a schematic diagram of five separate fan modules connected in series.

[0039] refer to figure 1 , figure 2 , the axial flow fan includes a fan casing 10 and five fan modules 20 connected in series with each other inside the fan casing 10 . After the five fan modules 20 are connected in series, the internal wind pressure of the axial flow fan 1 is increased. Five fan modules 20 are connected in series in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com