Intelligent fiber stretching mechanism for composite ES short fiber production

An intelligent, short-fiber technology, applied in textiles and papermaking, spraying/jetting textile material processing, etc., can solve the problems of low degree of automation, achieve convenient operation, reduce static electricity, and be suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

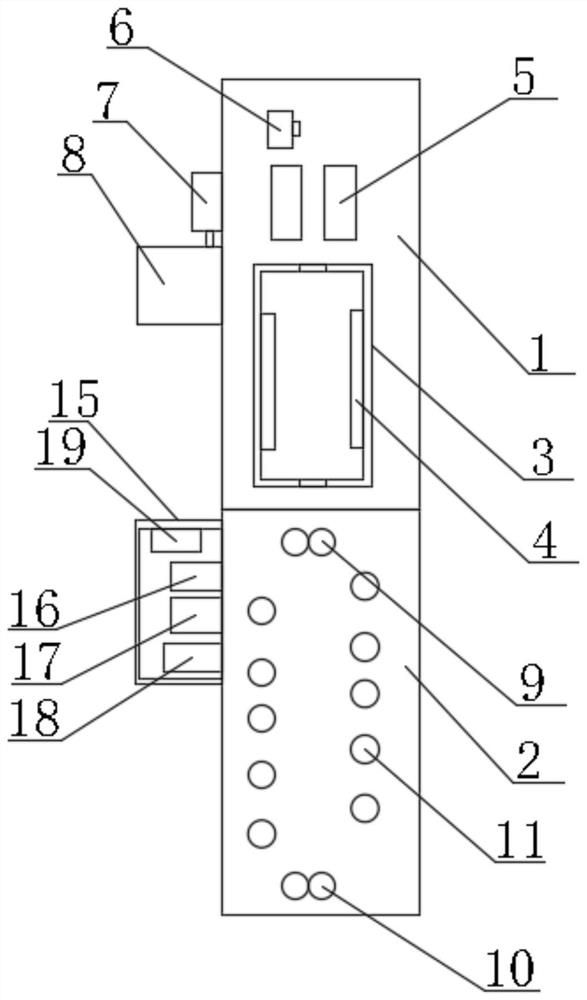

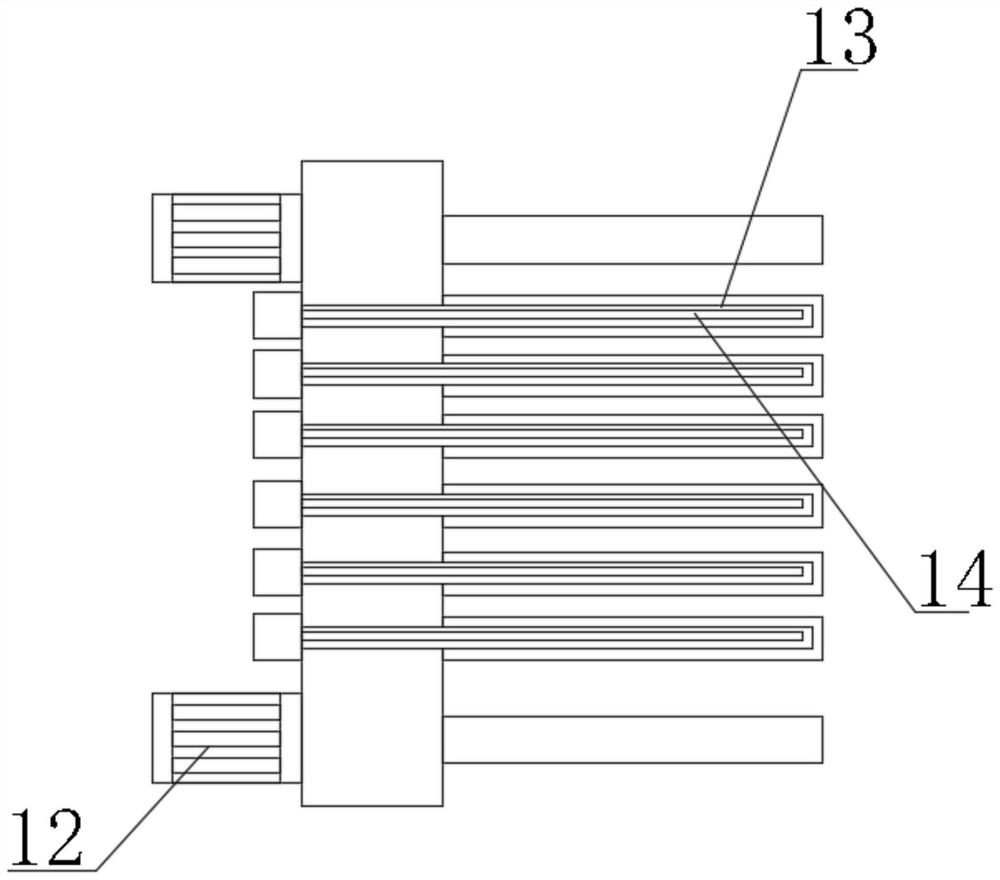

[0020] see Figure 1-2 , this embodiment provides a technical solution:

[0021] An intelligent fiber stretching mechanism for the production of composite ES short fibers, comprising an upper mounting frame 1 and a lower mounting frame 2, the upper mounting frame 1 is fixedly arranged on the top of the lower mounting frame 2, and the upper mounting frame 1 is fixed on the front side panel A preheating box 3 is provided, and the top panel and the bottom panel of the preheating box 3 are provided with feed troughs, and the front side panel of the upper installation frame 1 is fixedly provided with spray covers 5 on the left and right sides above the feed chute On the front side panel of the upper installation frame 1, a feed sensor 6 is fixedly arranged above the spray cover 5, and on the left side panel of the upper installation frame 1, a feed pump 7 and a drug box 8 are fixedly arranged sequentially from top to bottom, for supplying The pumping pipe of the feed pump 7 goes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com