Self-lifting vehicle ladder

A car ladder, a pair of technology, applied in the field of mechanical design, can solve the problems of high cost of parking spaces on the upper floor, waste of parking resources, etc., and achieve the effect of low cost, huge application potential, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

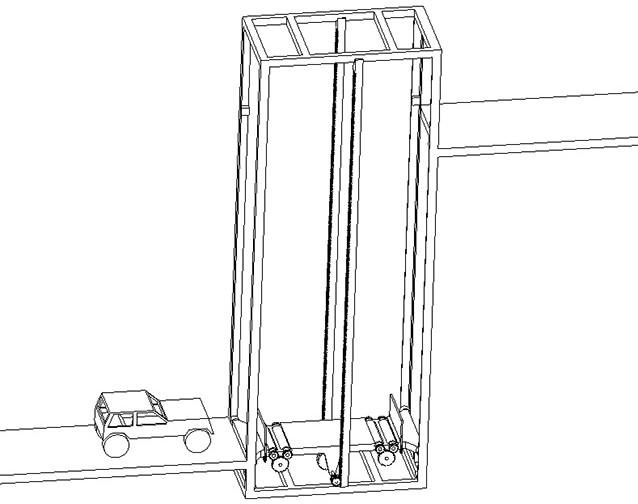

[0026] Assembly process: first follow the Figure 15 Assemble the main components in the same way, and then put the assembled vehicle lifting body body into the track. The effect after assembly is as follows: figure 1 shown.

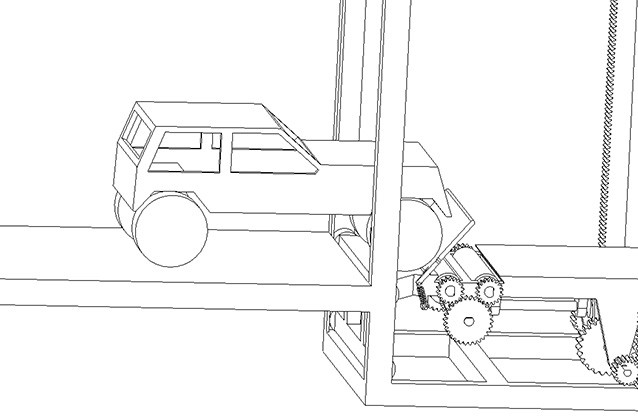

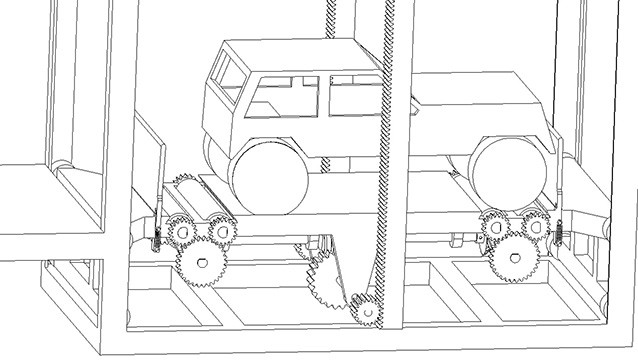

[0027] Working principle: as Figure 5 As shown, for a general front-drive vehicle, the power output is the front wheel, and the rotation of the front wheel on the two power rollers (14) will drive the two drive pinion gears (1) to rotate in the same direction, and the pinion gear (1) meshes The large driving gear (5) also starts to rotate, and the large driving gear (5) drives the small bevel gear (12) on the coaxial axis to rotate, and the small bevel gear (12) drives the large bevel gear (2) to rotate, and the rotation passes through the worm-bevel The transmission rod (8) transmits to the worm gear (3) and another set of symmetrical power rollers, and the worm gear (3) and the spur gear (10) transmit the driving force to the two ends of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com