Tailoring device facilitating garment processing and production

A cutting device and clothing technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy wear and tear of cutting tools, and achieve the effect of intelligent monitoring, convenient installation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

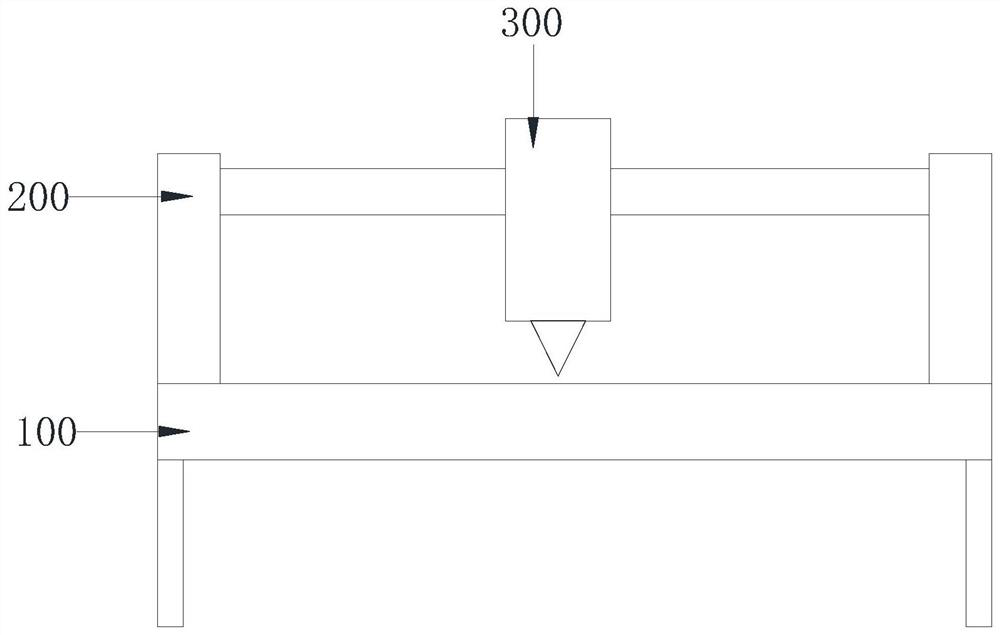

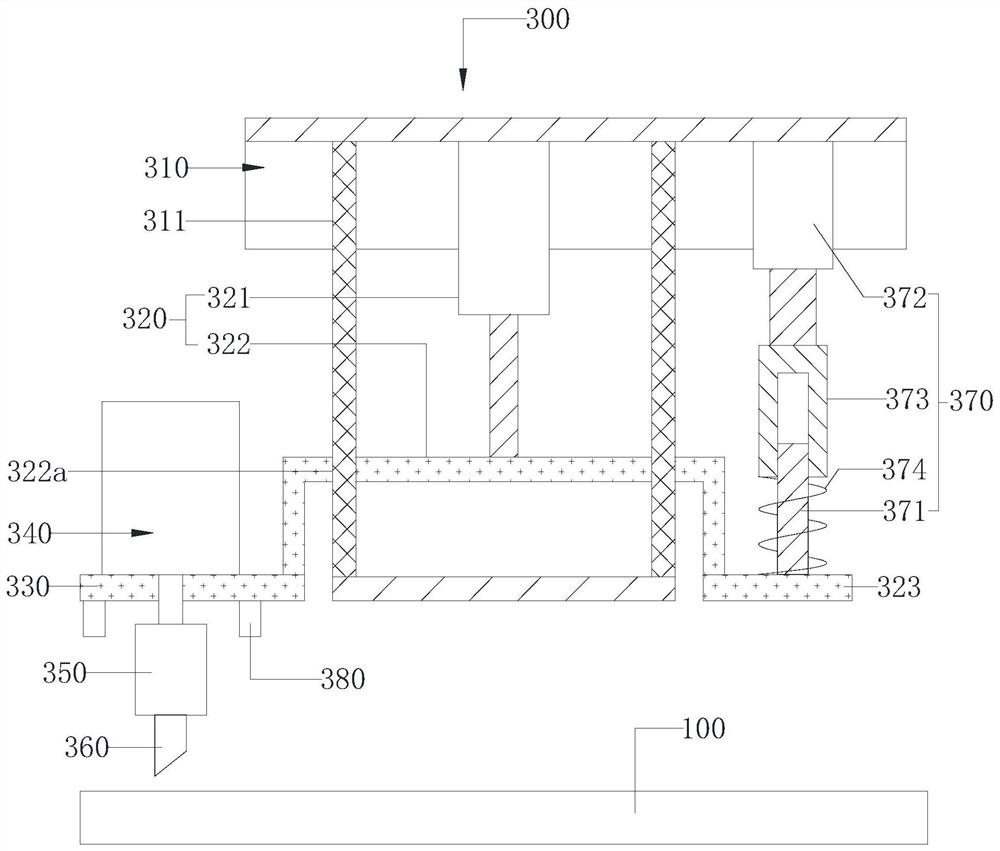

[0035] The invention provides a cutting device that is convenient for garment processing and production, see Figure 1-Figure 4 , including a machine tool 100, a moving mechanism 200 arranged on the machine tool, a cutting mechanism 300 is arranged on the moving mechanism 200, and the moving mechanism 200 drives the cutting mechanism 300 to move. When in use, the provided moving mechanism 200 drives the cutting mechanism 300 to move on the machine tool 100 , and during the moving process, the cutting mechanism 300 cuts the cloth on the machine tool 100 according to the designed cutting route.

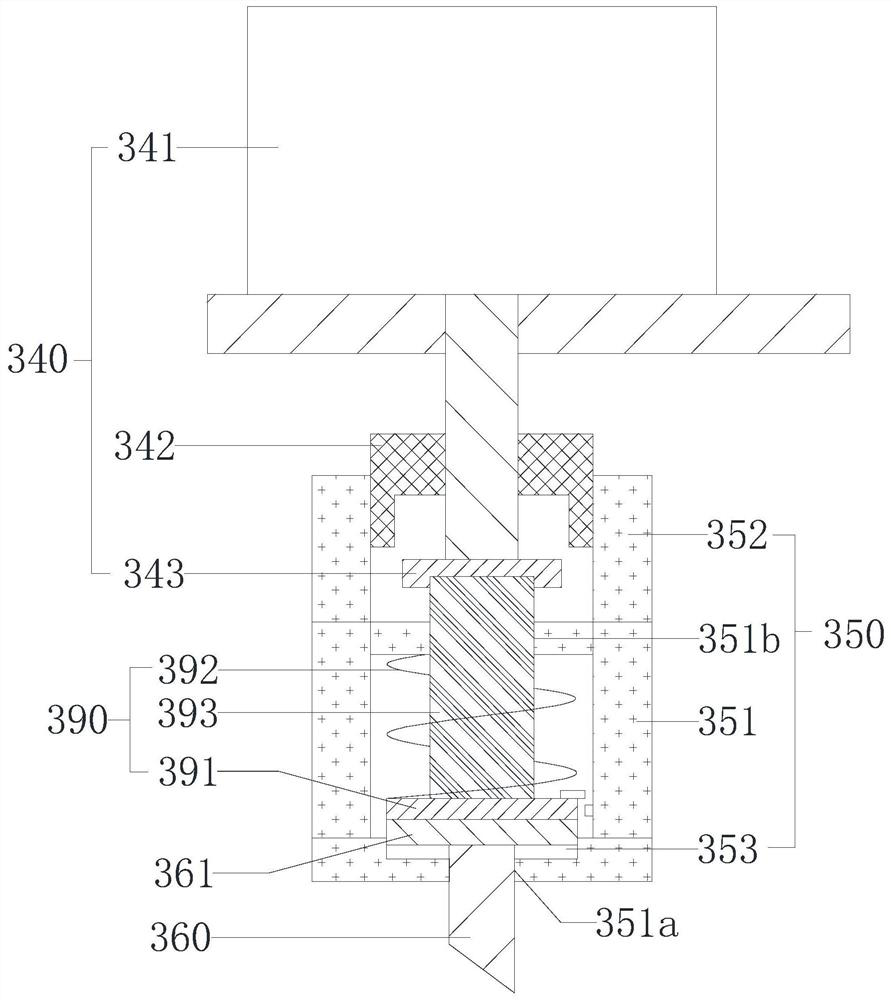

[0036] The cutting mechanism 300 includes a mounting frame 310 arranged on the moving mechanism 200, and a lifting assembly 320 is arranged on the mounting frame 310. The lifting end of the lifting assembly 320 is connected with a support plate 330, and the upper side of the support plate 330 is provided with a rotating assembly 340. The rotating end of the assembly 340 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com