Three-layer breathable weft-knitted fabric as well as production method and application thereof

A production method and technology for woven fabrics, which are applied in weft knitting, textiles, papermaking, knitting, etc., can solve the problems of monotonous visual effect and single function of sandwich fabrics, and achieve the effect of improving thermal insulation and excellent ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

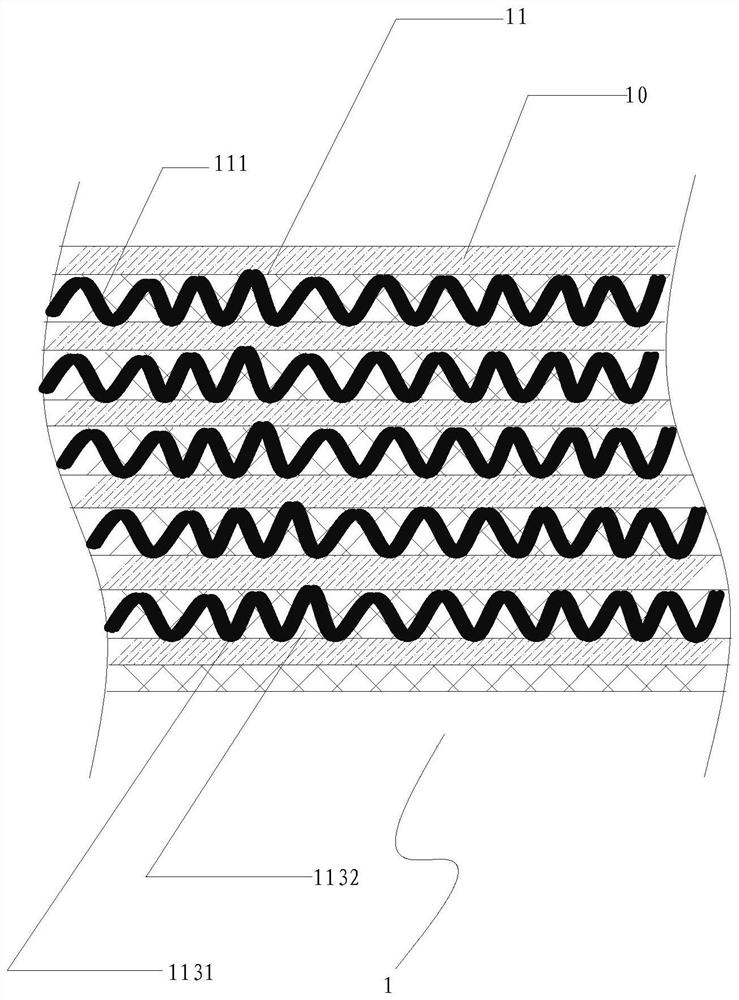

[0049] see figure 1 , This embodiment provides a color three-layer breathable weft knitted fabric and its production method and application.

[0050] The yarn clusters 1131 in the middle layer of the yarn-filling area 11 of the three-layer air-permeable weft knitted fabric 1 in this embodiment are space-dyed yarns DTY containing 5 colors. In other different embodiments, the yarns in the middle layer of the yarn-filling area The thread tufts can also be made of other polyester segment dyed yarns of different colors, the surface layer 111 is transparent elastic fishing silk, and the inner layer (not shown in the figure) is non-transparent white semi-gloss monofilament. After measurement, the width of the yarn filling area is 15mm, and the width of the flattening area 10 is 10mm. from figure 1 It can be seen that the colored segment dyed yarns are arranged in a natural twisted shape in the middle layer, and there are still many voids 1132 in the middle layer.

[0051] After te...

Embodiment 2

[0069] The present embodiment provides a non-see-through three-layer air-permeable weft knitted fabric and its production method and application.

[0070] The production method of the present embodiment is different from embodiment 1 in that:

[0071] Triangular arrangement: No. 1-6 * 8 times = 48 for the flat part, 15-16 * 18 * 18 for the yarn filling part = 36, 84 for one cycle; 40D / 1F monofilament for the first path, 2- 75D / 144F light mesh yarn for No. 48, 40D / 12F polyester filament FDY for No. 49-83 orders, 80D polyester fishing yarn for No. 50-84, and Spandex for No. 2-48 , No spandex is added to the 49th-84th road behind, and one 50S wool is added to each of the 59th, 63rd, 71st, 75th, 79th, and 83rd road.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com