A shuttle box with independent lifting and lowering of shuttle and reed

An independent lifting and reed technology, applied in textiles, papermaking, looms, textiles, etc., can solve the problems of limited applicability, shuttle running mode and capacity limitation of weft bobbins, and the inability of independent lifting of reeds, etc., to achieve The effect of continuous change in diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

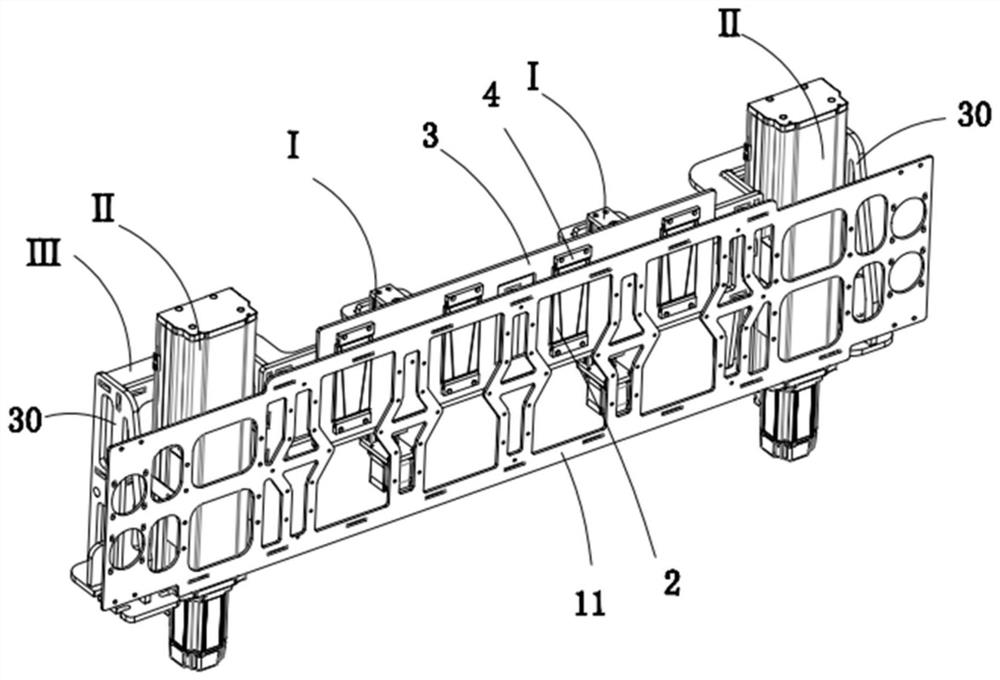

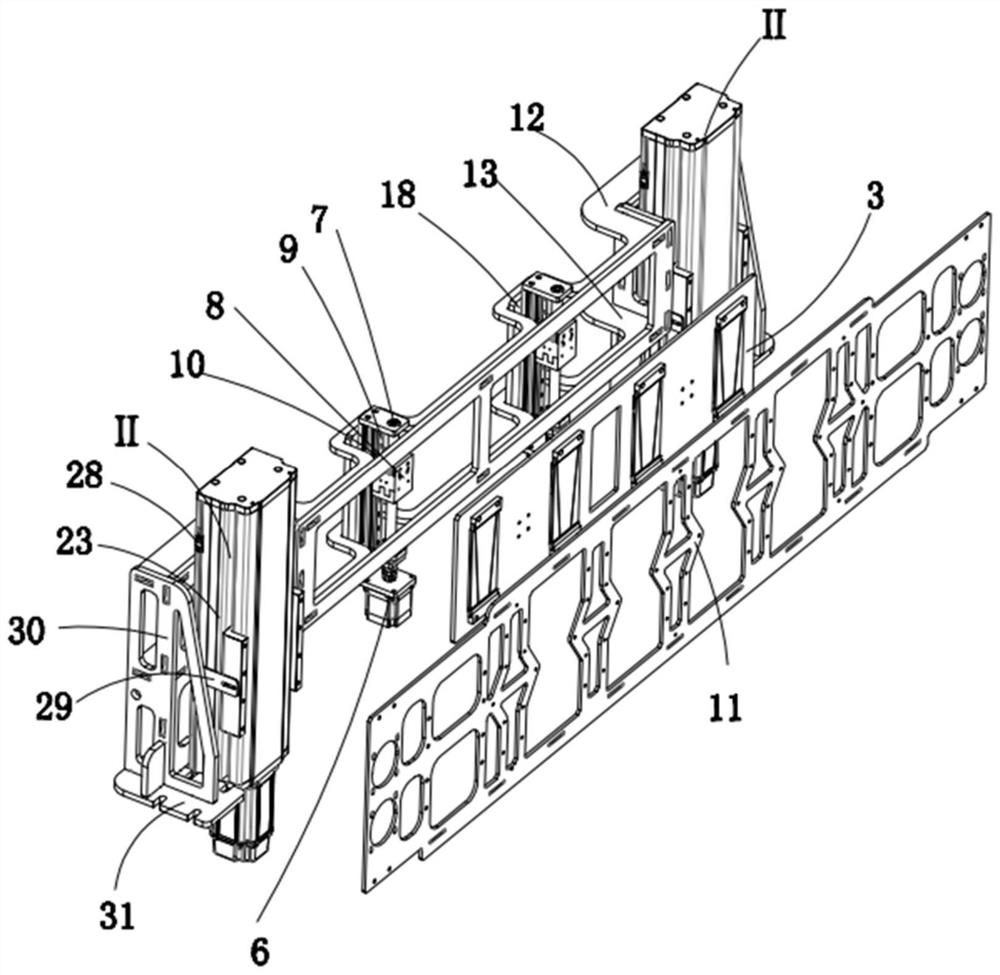

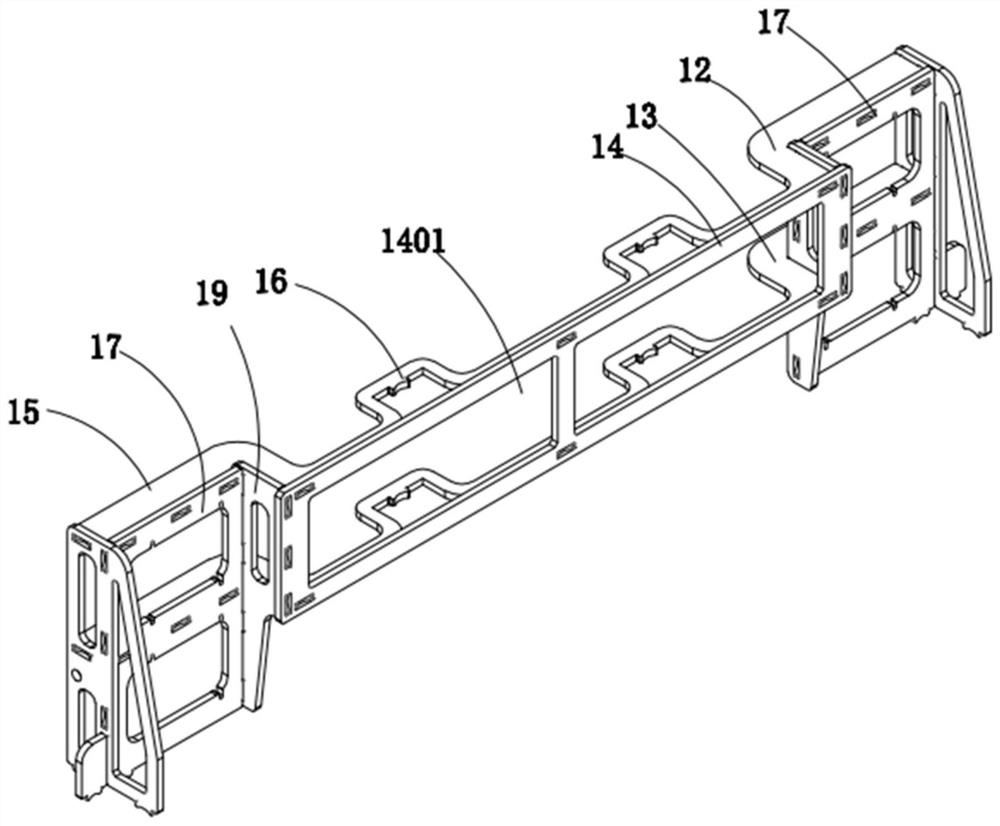

[0025] example, see attached Figures 1 to 6 , a shuttle box with independent lifting and lowering of shuttle and reed, including shuttle 1 and reed 2, and also includes a reed mounting plate 3 capable of fixing multiple groups of reeds side by side, and a reed lift capable of controlling the reed mounting plate to realize lifting and lowering motion Mechanism I; the reed is a V-shaped special-shaped reed structure; the special-shaped reed is provided with a wire-passing through groove 201 with a large upper section and a small lower section, and the upper and lower sections are fixed on the reed mounting plate. The lower reed is installed with pressing pieces 4 and 5, and the special-shaped steel reed is clamped between the upper and lower reed installation pressing pieces. The upper and lower reed installation pressing pieces are both L-shaped clips, a special-shaped steel reed is clamped between the two L-shaped clips, and the two ends of the special-shaped steel reed are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com