Ore pulp electrolysis continuous leaching device

A technology of pulp electrolysis and leaching, which is applied in the direction of improving process efficiency, can solve the problems such as the inability of electrolytic cells to work continuously, labor intensity of workers, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the following will be further described in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

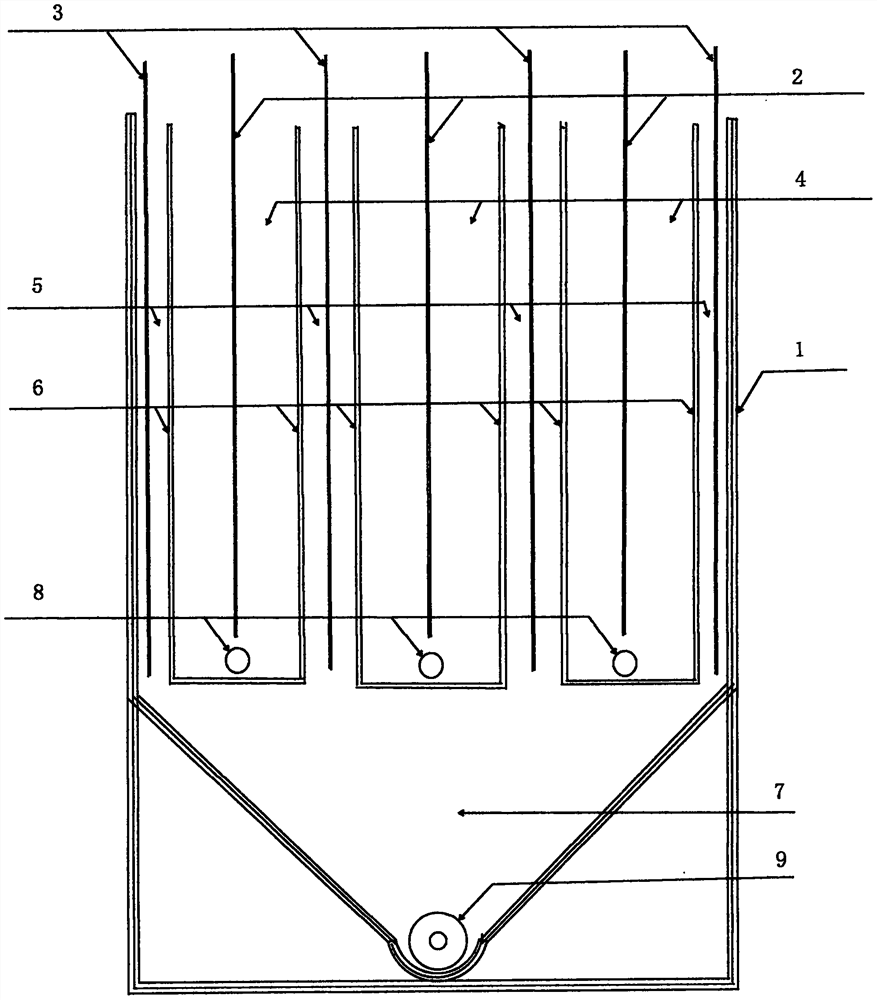

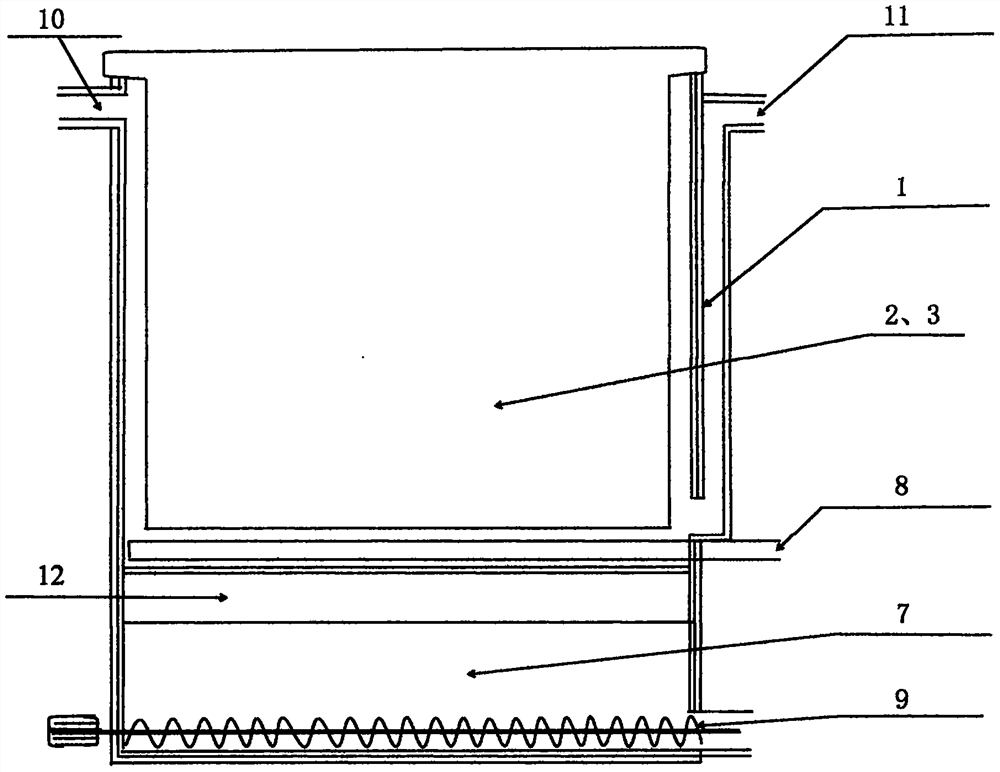

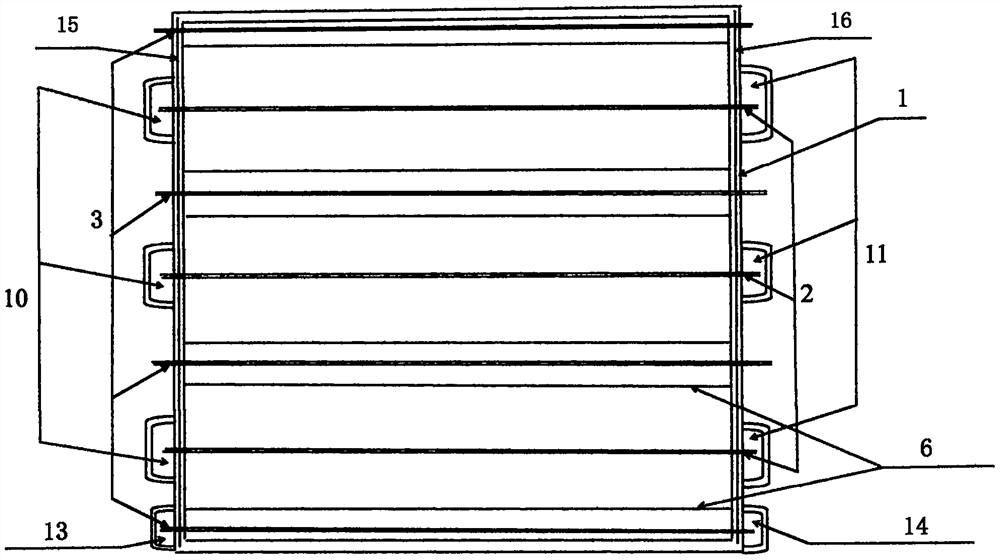

[0023] Such as figure 1 , 2 , Shown in 3, a kind of slurry electrolysis continuous leaching device, comprises square electrolyzer main body, anode area, cathode area, conical tank bottom and is formed, and the tank body is fixed with positive and negative conductive copper bars. The anode area and the cathode area are separated by a percolation diaphragm, the cathode area is connected with the bottom of the conical groove, and the bottom of the conical groove has a screw device to push out the metal mud, and the bottom of the anode area is equipped with a porous aeration device; the bottom of the anode area is equipped with Joists are heavy. The upper sides of the cathode area and the anode area of the electrolytic cell are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com