Sludge deep dehydration method and application of sludge

A deep dehydration and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, electrochemical sludge treatment, etc., can solve the problems of low treatment efficiency, large investment, high operating cost, etc., and achieve simple operation methods , high economic benefits, and the effect of improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

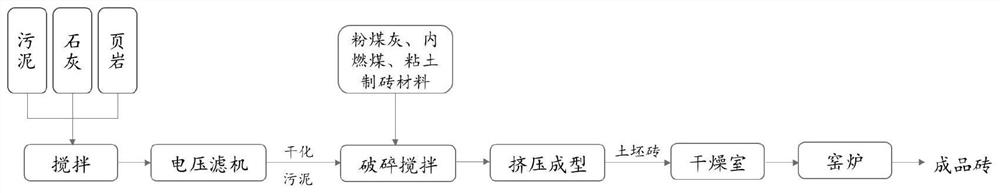

[0036] Take the sludge with a water content of 84.2% after dehydration by a plate and frame filter press from the sludge treatment plant, add lime with a sludge quality of 8‰, and shale with a sludge quality of 6‰, and mix evenly; send it to the electric filter press Drying and dehydration are carried out inside, the operating voltage is 22.4V, the operating current is 2.2A, the mechanical pressure is 1Mpa, and the action is 10min; after dehydration, the moisture content of the sludge reaches 58.1%.

[0037] The dried sludge is mixed with fly ash, internal combustion coal and clay at a ratio of 10% of the total mass, crushed and stirred evenly, extruded to make adobe bricks; the adobe bricks are placed in a drying room, and the drying temperature is The temperature is 190°C, and the drying time is 48 hours; finally, the dried adobe bricks are fired in a kiln with a maximum firing temperature of 1000°C for 100 minutes to obtain finished bricks, which meet the relevant constructi...

Embodiment 2

[0039] Take the sludge with a water content of 85.2% after dehydration by a plate and frame filter press from the sludge treatment plant, add lime with a sludge quality of 4‰, and shale with a sludge quality of 8‰, and mix evenly; send it to the electric filter press Drying and dehydration are carried out inside, the operating voltage is 22.4V, the operating current is 2.2A, the mechanical pressure is 1Mpa, and the action is 10min; after dehydration, the moisture content of the sludge reaches 57.7%.

[0040] The dried sludge is mixed with fly ash, internal combustion coal and clay at a ratio of 10% of the total mass, crushed and stirred evenly, extruded to make adobe bricks; the adobe bricks are placed in a drying room, and the drying temperature is The temperature is 200°C, and the drying time is 48 hours; finally, the dried adobe bricks are fired in a kiln with a maximum firing temperature of 1100°C for 90 minutes to obtain finished bricks, which meet the relevant constructio...

Embodiment 3

[0042] Take the sludge with a moisture content of 82.8% after dehydration with a plate and frame filter press from the sludge treatment plant, add lime with a sludge quality of 4‰, and shale with a sludge quality of 6‰, and mix evenly; send it to the electric filter press Drying and dehydration are carried out inside, the operating voltage is 22.4V, the operating current is 2.2A, the mechanical pressure is 2Mpa, and the action is 10min; after dehydration, the moisture content of the sludge reaches 54.1%.

[0043] The dried sludge is mixed with fly ash, internal combustion coal and clay at a ratio of 12% of the total mass, crushed and stirred evenly, and extruded to make adobe bricks; the adobe bricks are placed in a drying room, and the drying temperature is The temperature is 210°C, and the drying time is 48 hours; finally, the dried adobe bricks are fired in a kiln with a maximum firing temperature of 1150°C for 150 minutes to obtain finished bricks, which meet the relevant c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com