An Axial Adjustment Mechanism of Plate Roller in Book Printing Machine

An adjustment mechanism and printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve problems such as difficulty in ensuring high precision, unstable operation of equipment, and difficult control of adjustment errors, so as to achieve convenient maintenance and fast adjustment process Accurate and improve the effect of adjusting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

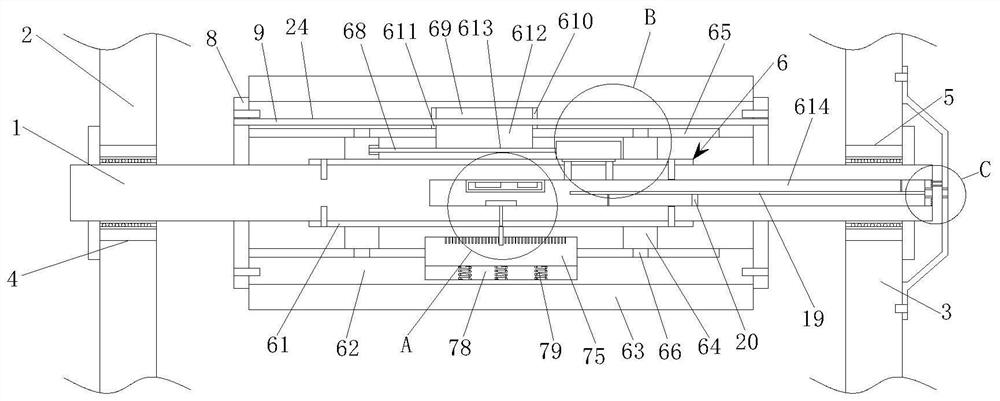

[0023] see Figure 1-5 , the present invention provides a technical solution: a printing plate roller axial adjustment mechanism of a book and periodical printing machine, including a transmission shaft 1, a left wall panel 2 and a right wall panel 3 distributed in parallel to the left and right, the left wall panel 2 and the right wall panel The corresponding positions on the 3 are provided with a mounting hole 1 4 and a mounting hole 2 5 respectively. Version roller fine-tuning mechanism6.

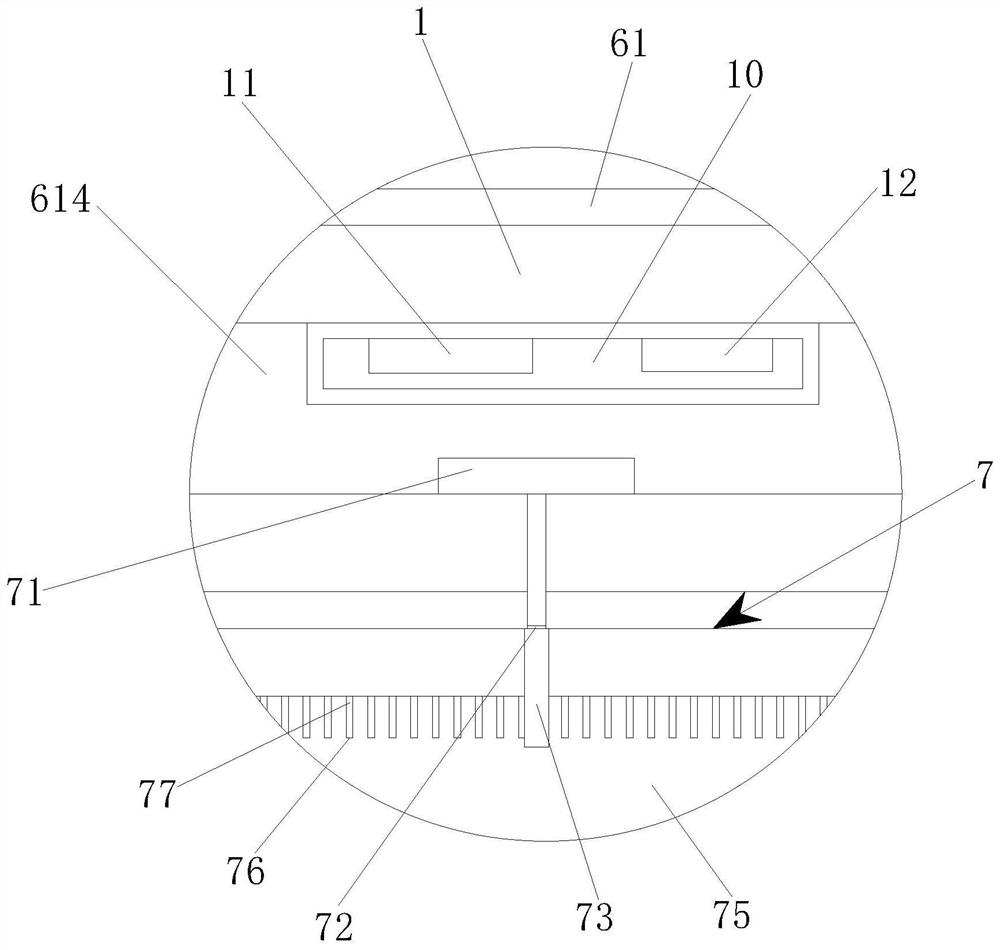

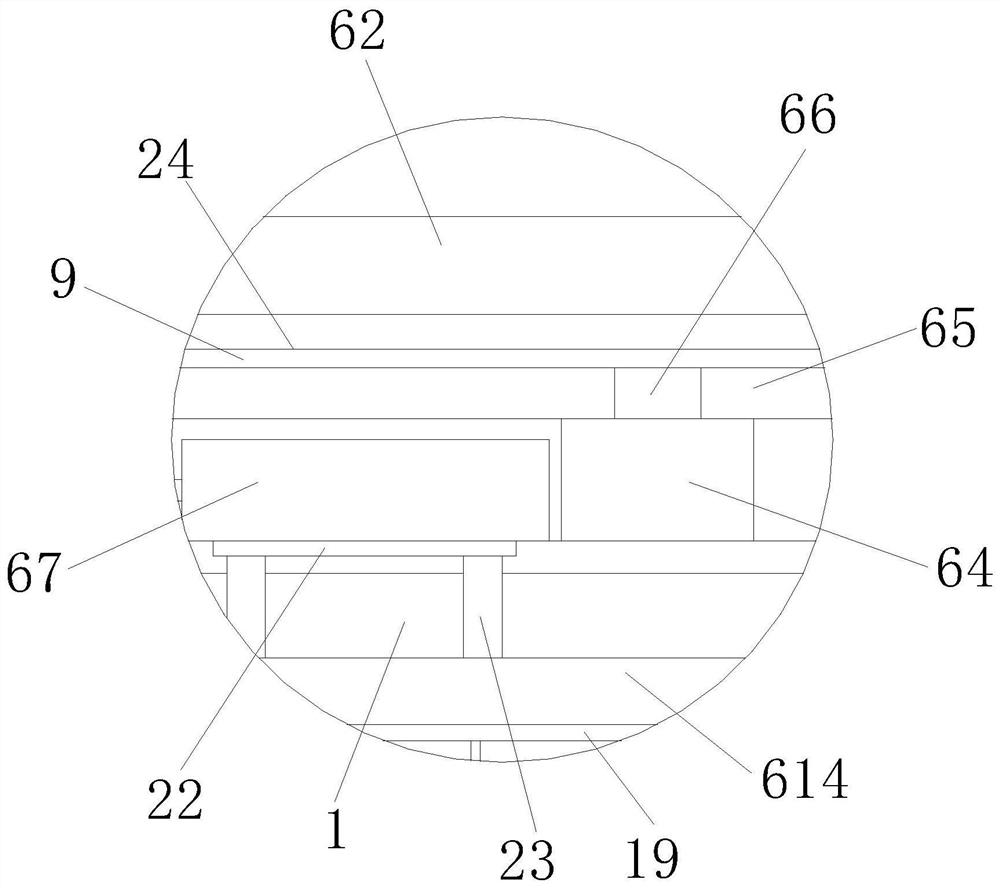

[0024] The plate roller fine-tuning mechanism 6 includes an inner sleeve 61, an outer sleeve 62, a printing sleeve 63, a support block 64, a guide groove 65, a guide block 66, a micro motor 67, a transmission screw 68, a receiving groove 69, a limit groove 610, and a limit block 611 , adjusting block 612, transmission screw groove 613 and device groove 614, the inner sleeve 61 is sleeved on the transmission shaft 1 and fixed by a bolt one, the outer sleeve 62 is sleeved on the outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com