A multi-stage vibration screening device for tobacco processing

A screening device and vibrating technology are applied in the field of multi-stage vibrating screening devices for tobacco processing, which can solve the problems of low vibration amplitude of the screening device, inability to conduct multi-stage screening of tobacco, and low quality of tobacco screening, so as to improve screening efficiency and improve efficiency. Quality, easy screening, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

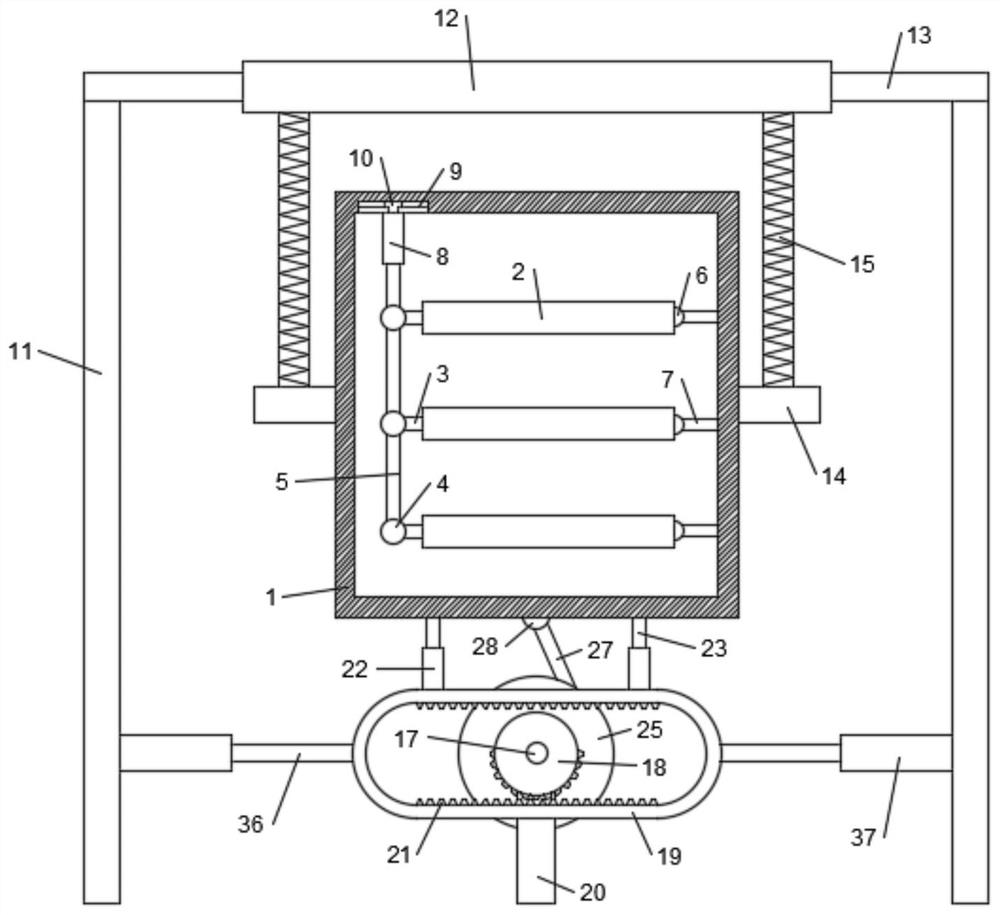

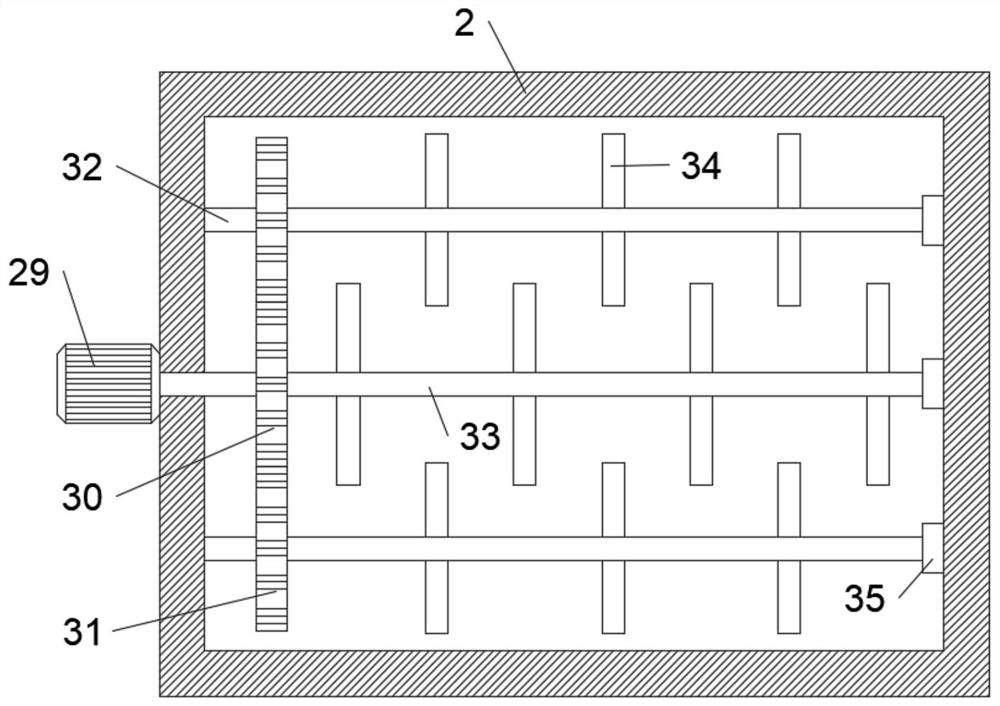

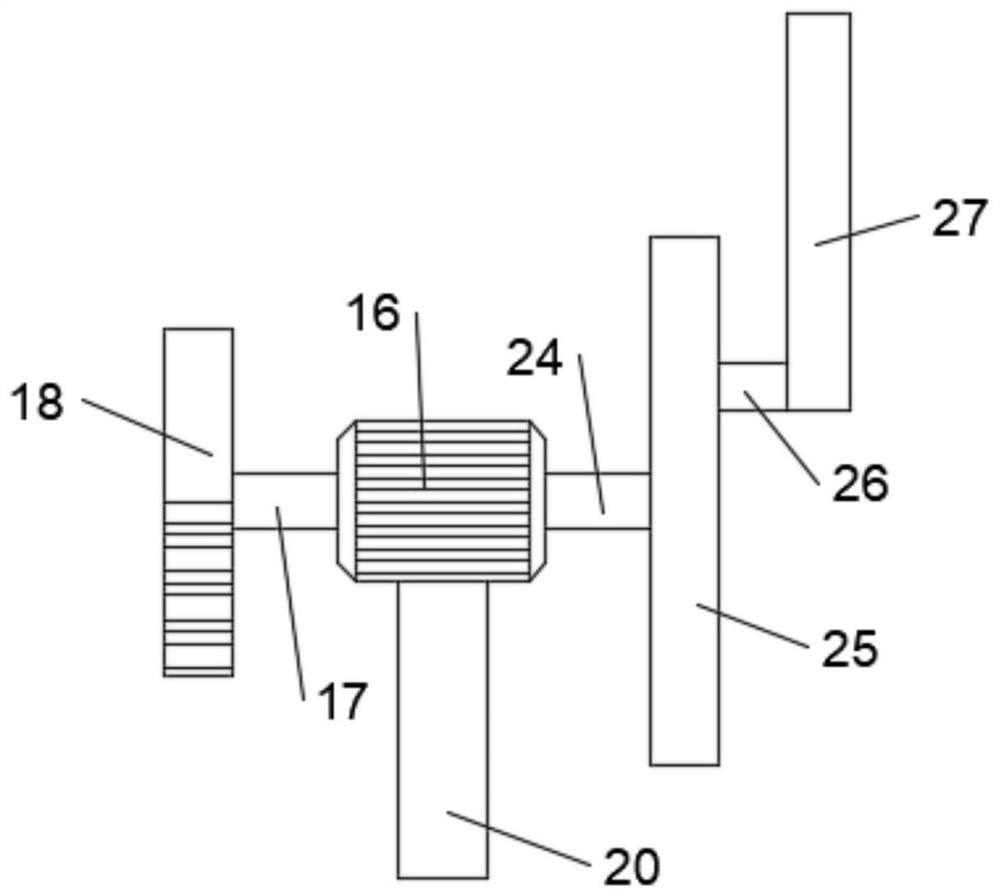

[0020] see Figure 1-3 , In the embodiment of the present invention, a multi-stage vibrating screening device for tobacco processing includes a box body 1, a plurality of screen buckets 2 are arranged in the box body 1, the screen buckets 2 are placed up and down, and the left end of the screen bucket 2 A connecting rod 3 is fixedly connected, the end of the connecting rod 3 is provided with a hinge shaft 1 4, a hinge rod 5 is hinged between the upper and lower hinge shaft 1 4, the right end of the screen bucket 2 is provided with a hinge shaft 2 6, and the hinge shaft 2 6 is hinged with A fixed rod 7, the end of the fixed rod 7 is fixedly connected to the inner side wall of the box body 1, the inner top of the box body 1 is provided with a chute 9, a slider 10 is slidably installed in the chute 9, and the slider 10 is fixedly connected with a telescopic rod 8. The end of the telescopic rod 8 is fixedly connected to the uppermost hinge shaft-4, the tobacco is placed in the upp...

Embodiment 2

[0027] In order to improve the stability of the device, this embodiment is further improved on the basis of Embodiment 1. The improvements are: sliding rods 36 are provided on the left and right side walls of the waist circle 19, and rod sleeves are provided on the inner side walls of the bracket 11 37. The sliding rod 36 is slidably installed in the rod sleeve 37. Through the rod sleeve 37, the waist circle 19 can be supported and limited, so that it can move stably left and right, thereby improving the stability of the device.

[0028] The working principle of this embodiment is: in order to improve the stability of the device, sliding rods 36 are provided on the left and right side walls of the waist circle 19, and rod sleeves 37 are provided on the inner side walls of the bracket 11, and the sliding rods 36 are slidably installed on the rod Inside the sleeve 37, through the rod sleeve 37, the waist circle 19 can be supported and limited, so that it can move left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com