Potato harvester

A harvester and potato technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of poor soil separation effect, soil is not easy to separate potatoes, and soil is difficult to shake off. The effect of damage, soil fragmentation rate improvement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

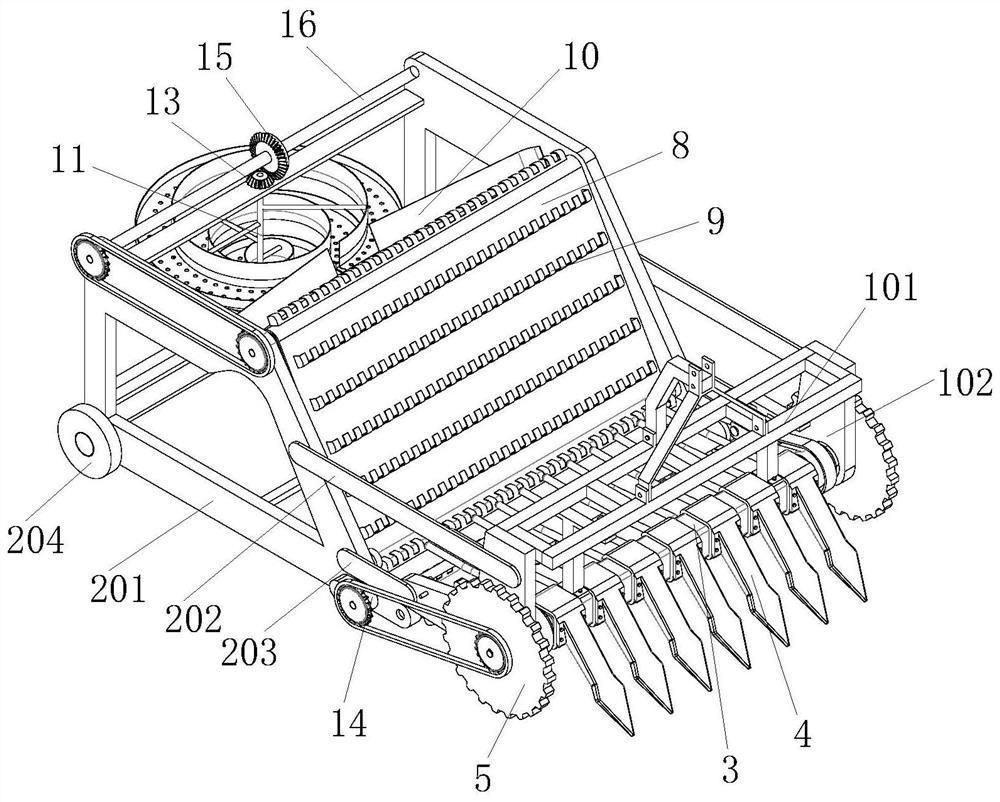

[0045] see Figure 1 to Figure 16, a potato harvester, comprising a first frame 1 and a second frame 2 fixedly attached to the rear end of the first frame 1 . The first frame 1 includes a horizontal support 101 , a first side plate 102 fixedly connected to the bottom of both sides of the horizontal support 101 , and a connecting frame 103 fixedly connected to the top of the horizontal support 101 . like Figure 5 and Image 6 As shown, the horizontal support 101 is a square frame welded by square pipes; the first side plate 102 is vertically arranged and fixed on both sides of the horizontal support 101 by bolts; the connecting frame 103 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com