Highway camera with cleaning structure

A highway and camera technology, applied in image communication, camera body, cleaning methods and utensils, etc., can solve the problems of dust on the camera lens, increase the labor intensity, and the cleaning effect is not ideal, etc. the effect of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

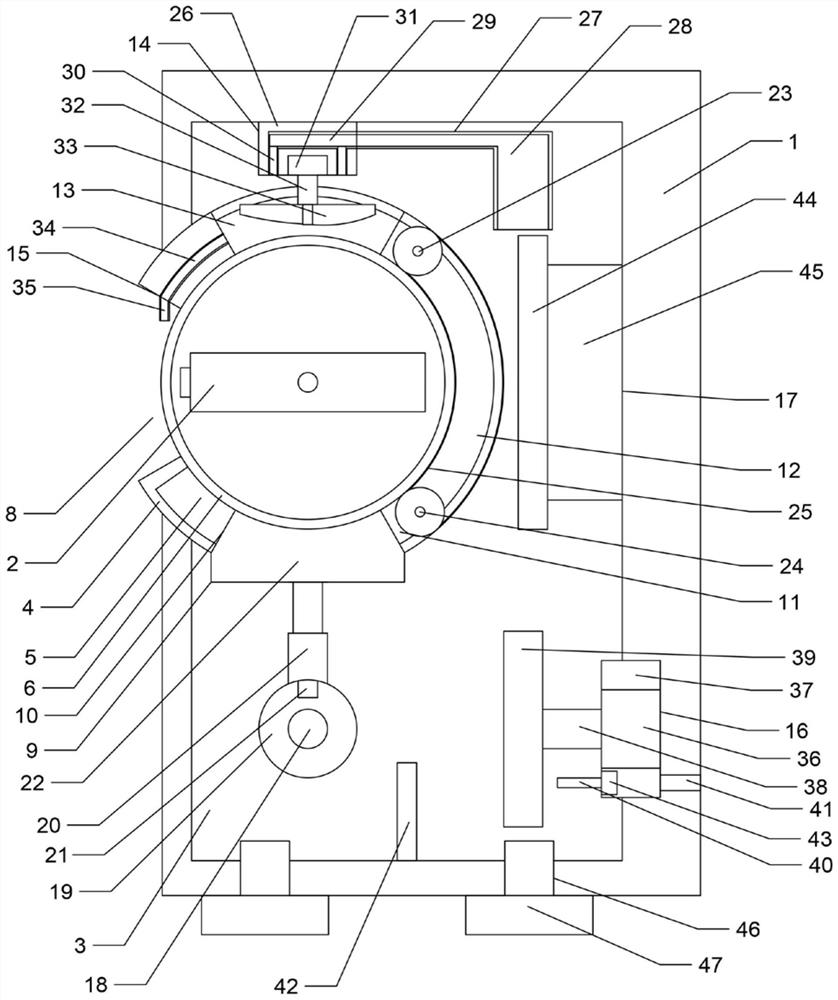

Embodiment 1

[0018] Embodiment 1: see figure 1, in this embodiment, since the camera is located in the spherical transparent cover. The dust on the highway will not have any contact with the body of the camera, and the dust will directly fall on the outer wall of the spherical transparent cover. Therefore, in this embodiment, it is only necessary to clean the spherical transparent cover. At the same time, since the spherical transparent cover is a transparent cover made of plastic, any rotation of the spherical transparent cover will not affect the normal operation of the camera. In this embodiment, when the spherical transparent cover needs to be cleaned, the first motor in the first accommodating cavity will rotate the first rotating shaft to make the spherical transparent cover roll circumferentially in the spherical accommodating cavity, When the part of the spherical transparent cover that needs to be cleaned is rotated to the first cleaning mechanism, the cylinder in the first fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com