A flameproof three-phase motor

A three-phase motor, explosion-proof technology, applied in the field of electric motors, can solve the problems of unsafe and reliable use, hidden dangers of user safety, high internal temperature, etc., and achieve the effects of stable and safe operation, convenient and stable installation, and convenient explosion-proof treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

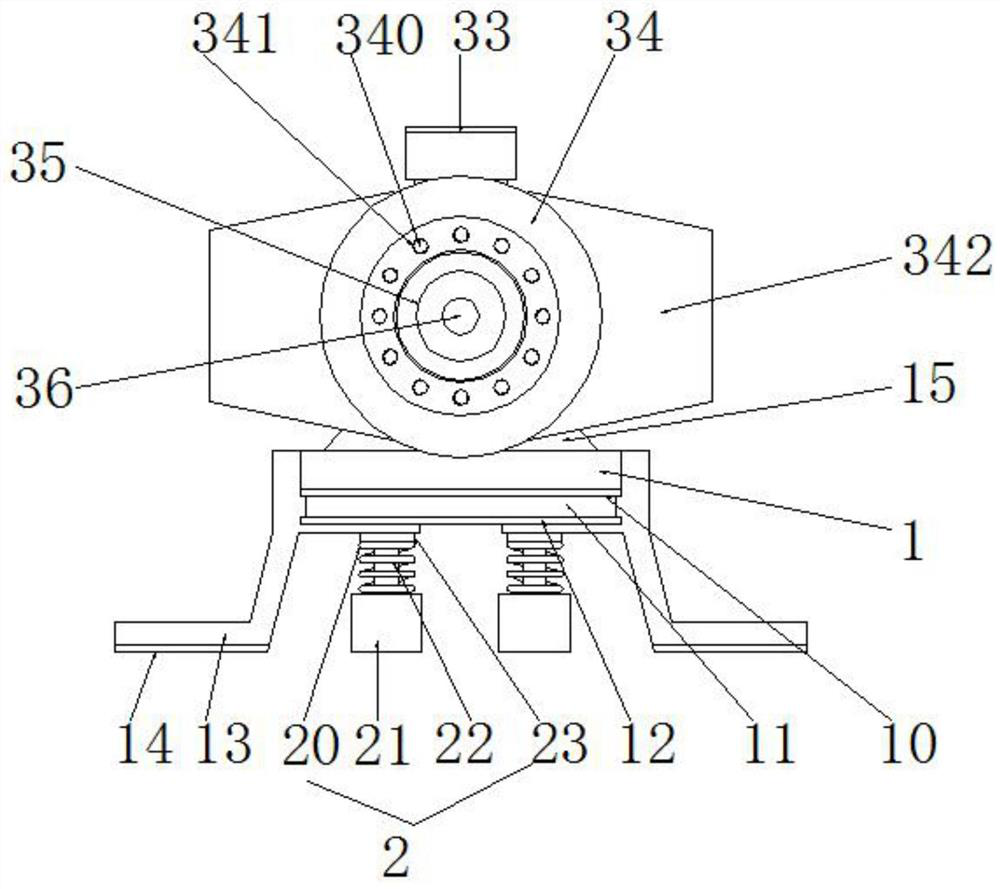

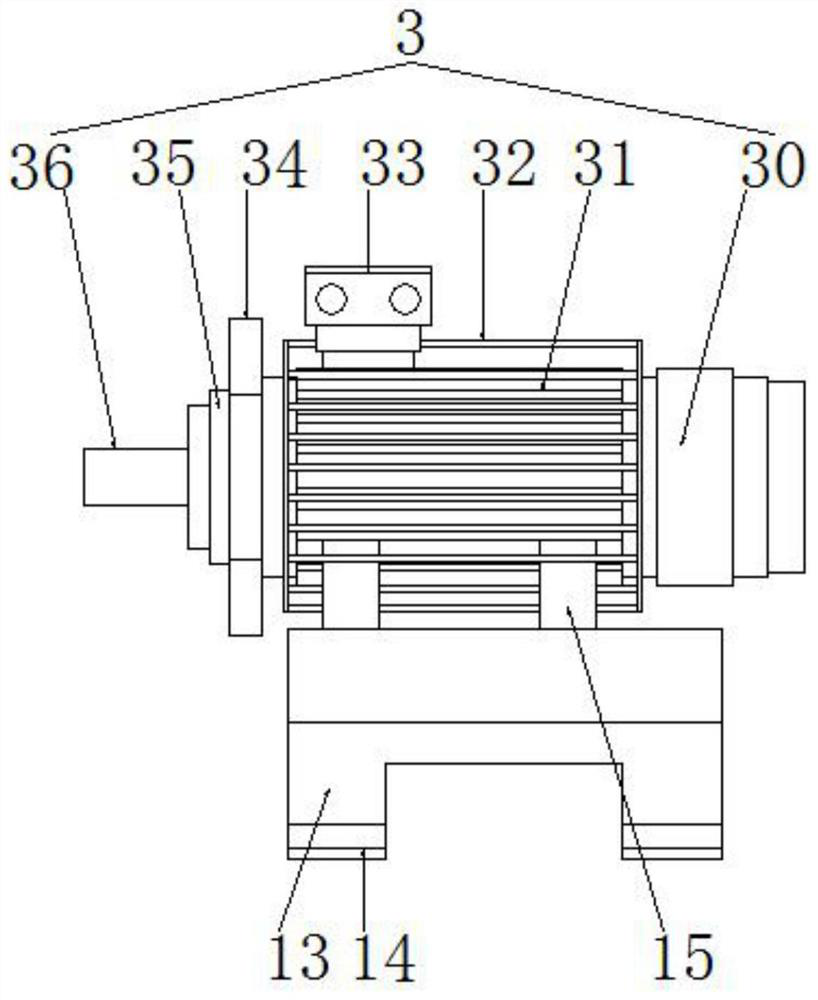

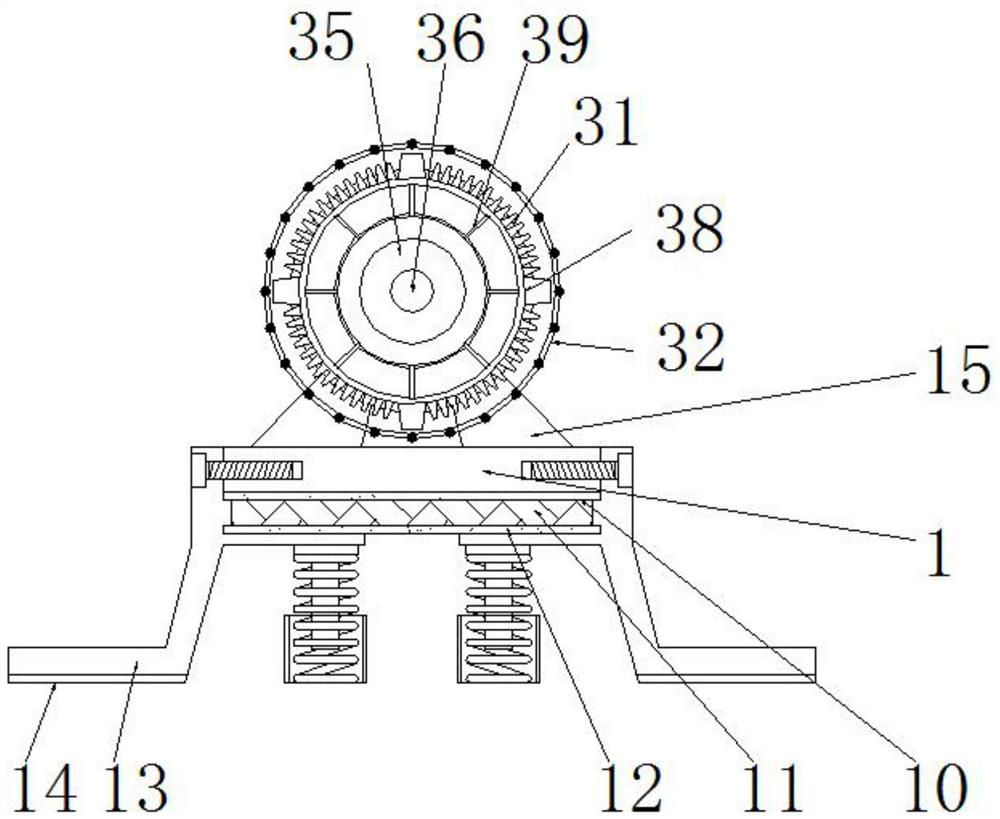

[0030] Specific embodiment of one, see Figure 1-7 , the present invention provides a flameproof three-phase motor, comprising a base 1, a shock absorption mechanism 2 and a motor structure 3, the base 1 is installed on the motor structure 3, the upper end of the middle of the motor structure 3 is provided with a junction box 33, and the inner bottom of the base 1 is installed on the front side and the rear side of the two sets of shock absorption mechanism 2, the front side of the motor structure 3 is provided with a protective panel 34, the middle of the protective panel 34 is provided with multiple sets of screw holes 341, and the screw hole 341 is installed with fastening screws 340, And the left and right sides of the protective panel 34 are provided with fixed side plates 342, and the center of the protective panel 34 is provided with a front sealing plate 35, and the center of the front sealing plate 35 is installed with a front shaft 36, the external of the motor structure ...

specific Embodiment approach 2

[0031]Specific embodiment two, the present invention is provided mainly for supporting the motor structure 3, while the bottom of the base 1 is provided on the anti-slip pad 10, buffer layer 11 and lower anti-slip pad 12, the upper anti-slip pad 10 and the lower anti-slip pad 12 is provided for anti-slip treatment, so that the installation of the buffer layer 11 can not be relaxed, and the use of the buffer layer 11 to effectively reduce the buffer, convenient and better stability of the motor.

specific Embodiment approach 3

[0032] Specific embodiment three, the present invention in the base 1 of the bottom front side and the rear side are installed on the shock absorption mechanism 2, the upper and lower ends of the shock absorption mechanism 2 are provided with a top plate 23 and a guide sleeve 21, the top plate 23 under the positioning rod 22 sets placed in the shock absorbing spring 20, helps to carry out straight directional shock absorption, can buffer a part of the vibration impact in the vertical direction, so that the equipment storage is more stable and safe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com