Temperature sensor dynamic calibration method based on dual temperature excitation

A temperature sensor, dynamic calibration technology, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as time constant change, and achieve the effect of reducing uncertainty, suitable for promotion, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

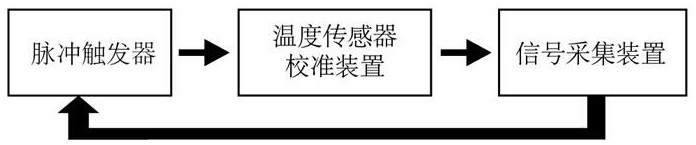

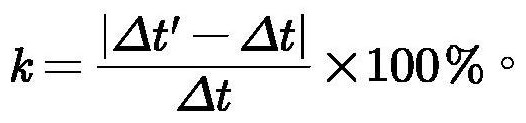

[0027] Example: see figure 1 , first install the temperature sensor to be calibrated on the temperature sensor calibration transposition, connect the lead wire of the temperature sensor to the signal acquisition device, then use the pulse trigger to generate a pulse signal A, trigger the temperature sensor calibration device to give a temperature excitation to the sensor to be calibrated, Use the temperature sensor signal acquisition device to collect the response signal a of the first temperature excitation of the sensor. After an interval of 1s, the pulse trigger generates the second pulse signal B, which triggers the temperature sensor calibration device to give the second temperature excitation to the temperature sensor to be calibrated. The sensor generates the response signal b of the second temperature excitation, and the response signal b is collected by the temperature sensor signal acquisition device. At this time, the time interval between the two response signals a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com