An optimized wind turbine blade deicing method

A technology for wind turbine blades and blades, which is applied in the field of optimized wind turbine blade deicing, and can solve problems such as increasing the weight of wind turbines, affecting the economic benefits of wind farms, and additional vibration of wind rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following description provides many different embodiments, or examples, for implementing various features of the invention. The elements and arrangements described in the following specific examples are only used to express the present invention in a concise manner, and are only used as examples rather than limiting the present invention.

[0040] An optimized wind turbine blade deicing method, comprising the following steps:

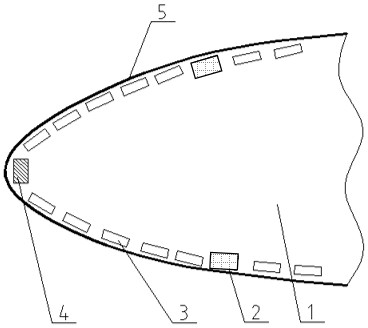

[0041] S10. The wind turbine blade 1 is divided into regions, divided into a high-power continuous heating zone, a low-power continuous heating zone and a periodic heating zone; correspondingly, a high-power continuous electric heating unit 4 is set in the high-power continuous heating zone, A low-power continuous electric heating unit 2 is set in the power continuous heating area, and a periodic electric heating unit 3 is set in the periodic heating area;

[0042] like figure 1 As shown, the high-power continuous heating zone is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com