Circulating mutual-climbing lifting column and application method thereof

A lifting column, tower column technology, applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of low turnover rate of embedded parts, setting up many machines, increasing hidden dangers, etc., to reduce freedom Cantilever height, safe climbing process, and the effect of improving wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

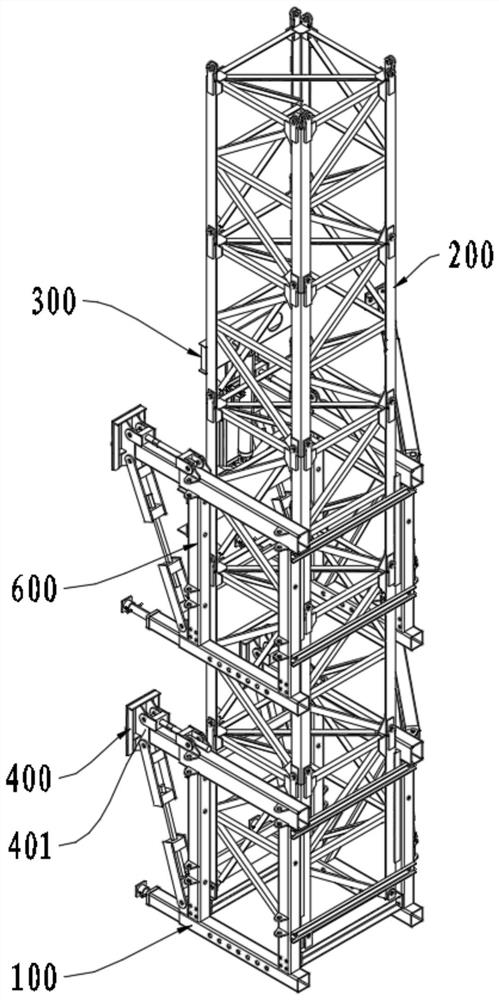

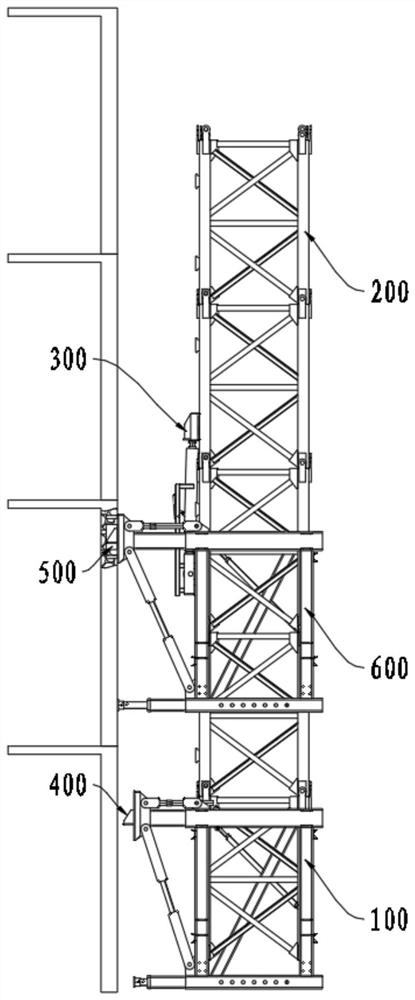

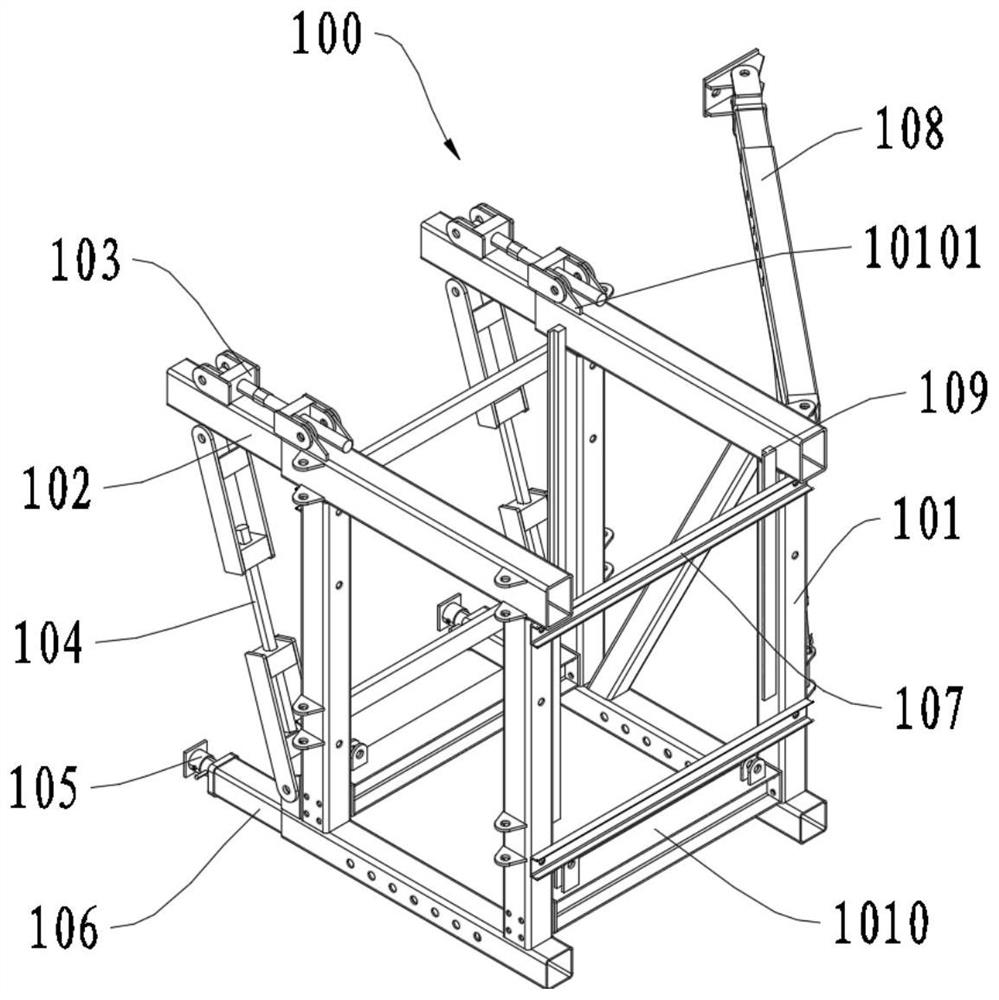

[0051] see Figure 1-8 , the present invention provides a cyclic inter-climbing lifting column including a lower support frame 100, the lower support frame 100 includes a load-bearing truss 101, and a connecting truss is fixedly connected between the front and back of the two load-bearing trusses 101 and near the top and bottom 107, between the bottoms of the two load-bearing trusses 101 and close to both ends are fixedly connected with tower connecting beams 1010, the top of the load-bearing trusses 101 is slidably connected with load-bearing telescopic beams 102, and the top surface of the load-bearing trusses 101 is fixedly connected with connecting plates 10101 , the connecting plate 10101 is hinged to one end of the upper adjusting cross bar 103, one end of the bottom of the load-bearing truss 101 is hinged to one end of the adjusting diagonal stay rod 104, and the other ends of the upper adjusting cross bar 103 and the adjusting diagonal stay rod 104 are hinged to the emb...

Embodiment 2

[0073] Please refer to Figure 9 , 10 , 11. The present invention provides a method for using a circular inter-climbing lifting column, comprising the following steps:

[0074] S1. For the installation of the cyclic inter-climbing lifting column, the load-bearing telescopic beam 102 of the lower support frame 100 is telescopically adjusted on the load-bearing truss 101, and the threaded rod 10303 is driven to rotate by turning the adjusting nut 10304, so that the gap between the two tension blocks 10302 becomes smaller. large, so as to drive the hinged ear 10301, the embedded part hanger 400 and the load-bearing telescopic beam 102 to move until the embedded part hanger 400 is docked with the embedded part system 500 pre-embedded in the building structure, and is fixed by a turnable high-strength bolt assembly Connect, then extend to a suitable length by sliding the supporting telescopic beam 106 at the bottom of the load-bearing truss 101, and fix the relative position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com