Cellulose reinforced polypropylene resin composite material as well as preparation method and application thereof

A technology of polypropylene resin and composite materials, applied in the field of composite materials, can solve the problems of plastic feeling and other problems, and achieve the effects of low density, low VOC content and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of Cellulose Reinforced Polypropylene Resin Composite

[0056] According to the second aspect of the present invention, there is provided a method for preparing the above-mentioned cellulose-reinforced polypropylene resin composite material, which is characterized in that the corresponding raw materials are mixed, melted, extruded, cooled and pelletized.

[0057] The corresponding raw materials described in this application refer to the raw materials required to constitute the cellulose-reinforced polypropylene resin composite material. Specifically, the corresponding raw materials refer to polypropylene resin, cellulose filler and dyed rayon defined for cellulose-reinforced polypropylene resin composite materials, as well as optional pigments, antioxidants, light stabilizers, release agents, One or more of free radical scavengers and compatibilizers.

[0058] The melting process is performed at a temperature that melts the polypropylene resin.

[0059] ...

Embodiment 1

[0086] Mix polypropylene resin, cellulose filler, white pigment, black rayon, compatibilizer, antioxidant, light stabilizer, free radical scavenger, etc. according to the amounts shown in Table 1, and then use it at 190-230ºC ZSK-25 type twin-screw extruder (from Coperion Company) is extruded, and feeding speed is 800-1200Kg / h, and screw speed is 500-800rpm, obtains slice after cooling, dicing.

[0087] Table 1

[0088]

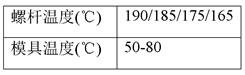

[0089] The obtained slices were processed into a test sample (with a size of 150mm*100mm*2mm) using the injection molding process shown in Table 2.

[0090] Table 2 Injection molding process

[0091]

[0092] figure 1 Photographs of the surface appearance of the prepared cellulose-reinforced polypropylene resin composite samples are shown. It has a uniform matte look and a two-tone effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com