Preparation method of ceramic tile, and ceramic tile

A technology of ceramic tiles and ceramic tiles, applied in the field of ceramic tiles, can solve the problems of weak paving, troublesome, low water absorption, etc., and achieve the effect of not firm paving, not easy to fall off, and high adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

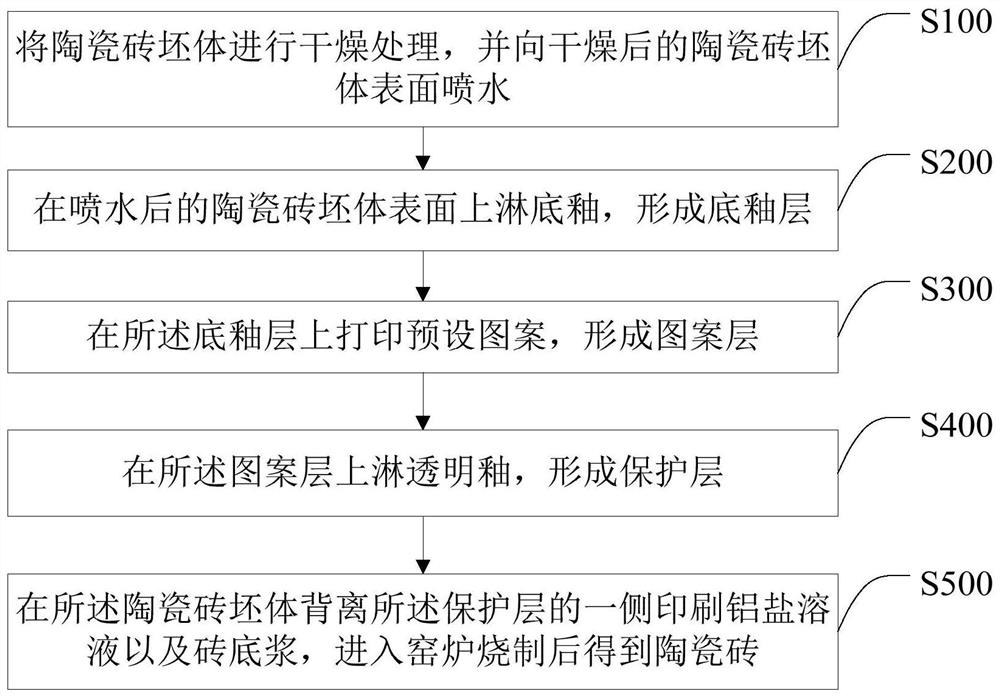

[0040] see figure 1 , figure 1 It is a flow chart of the preparation method of ceramic tiles in the present invention. Such as figure 1 Shown, the preparation method of the ceramic tile described in the embodiment of the present invention comprises the following steps:

[0041] Step S100 , drying the ceramic tile body, and spraying water on the surface of the dried ceramic tile body.

[0042] In an implementation manner, before the step S100, the step S100 further includes: obtaining a ceramic tile body after the ceramic raw material is pressed and formed by a press. Wherein, the back side of the ceramic brick body has back grain wattle.

[0043] Specifically, after the tiles are pressed and formed by a press, due to the presence of certain moisture in the green body, the green body must first enter a drying kiln for drying to evaporate part of the water. When applying the underglaze on the ceramic surface, in order to allow the underglaze to better adhere to the surface ...

Embodiment 1

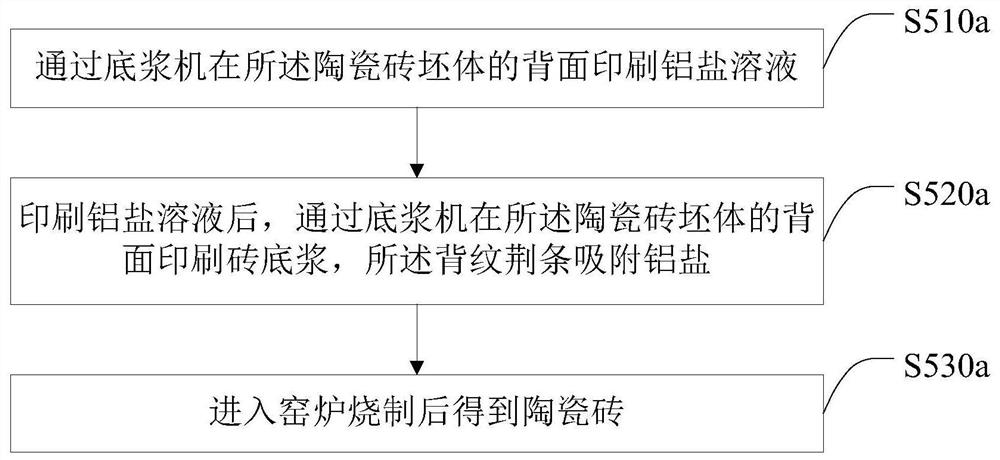

[0070] see Figure 4 , the preparation method of ceramic tile specifically comprises:

[0071] Step A1, after the ceramic raw material is pressed and formed by a press, a ceramic tile body is obtained, and the back side of the ceramic tile body has Vitex japonica;

[0072] Step A2, drying the ceramic tile body, and spraying water on the surface of the dried ceramic tile body;

[0073] Step A3, pouring an underglaze on the surface of the ceramic tile body after water spraying to form an underglaze layer;

[0074] Step A4, printing a preset pattern on the underglaze layer to form a pattern layer;

[0075] Step A5, pouring a transparent glaze on the pattern layer to form a protective layer;

[0076] Step A6, printing an aluminum salt solution on the back of the ceramic tile body through a primer;

[0077] Step A7, after printing the aluminum salt solution, print magnesia slurry on the back of the ceramic tile body through a primer machine, and the Vitex dorsalis absorbs the a...

Embodiment 2

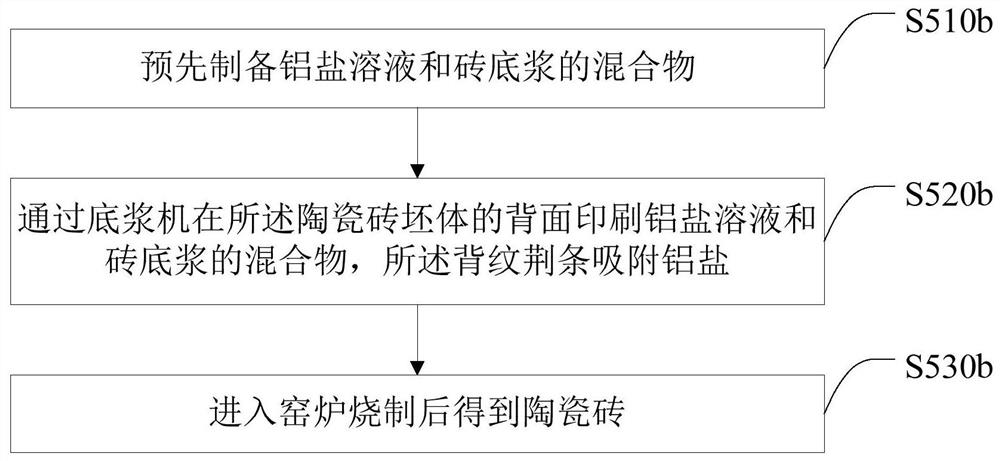

[0080] see Figure 5 , the preparation method of ceramic tile specifically comprises:

[0081] Step B1, after the ceramic raw material is pressed and formed by a press, a ceramic tile body is obtained, and the back side of the ceramic tile body has Vitex vitex;

[0082] Step B2, drying the ceramic tile body, and spraying water on the surface of the dried ceramic tile body;

[0083] Step B3, pouring an underglaze on the surface of the ceramic tile body after water spraying to form an underglaze layer;

[0084] Step B4, printing a preset pattern on the underglaze layer to form a pattern layer;

[0085] Step B5, pouring a transparent glaze on the pattern layer to form a protective layer;

[0086] Step B6, printing a mixture of aluminum salt solution and magnesia slurry prepared in advance on the back of the ceramic tile body through a primer, and the Vitex dorsalis absorbs aluminum salt;

[0087] B7. Ceramic tiles are obtained after firing in a kiln.

[0088] The present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com