Pressurized carbonization device for bulk solid waste after alkalization treatment

A solid waste and alkalization treatment technology, which is applied in the direction of solid waste removal, transportation and packaging, chemical instruments and methods, etc., can solve the troublesome problems of putting into a pressurized carbonization device, inconvenient bulk solid waste, and transportation, etc., to achieve The processing process is perfect, the effect of carrying and simple operation is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

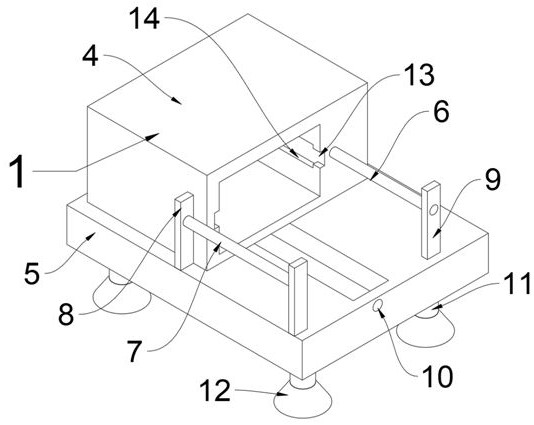

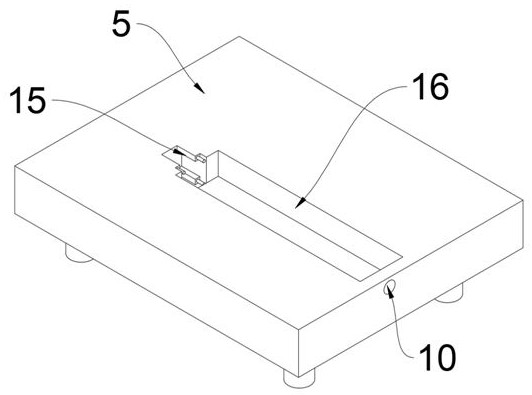

[0034] A pressurized carbonization device after alkalization treatment of bulk solid waste, such as figure 1 As shown, it includes a fixing device 1, the inside of the fixing device 1 is slidingly connected with a pushing device 2, and the inside of the pushing device 2 is clamped and fixed with a loading device 3, as figure 2 , 3As shown, the fixing device 1 includes a pressurized carbonization box 4, a bottom plate 5, a first connecting column 6, a second connecting column 7, a first positioning plate 8, a second positioning plate 9, a first positioning hole 10, a supporting column 11, The base 12, the first moving groove 13, the second moving groove 14, the mounting groove 15 and the positioning groove 16, the base plate 5 is arranged inside the fixing device 1, the support columns 11 are fixedly connected to the four corners of the lower end surface of the base plate 5, and the base 12 is fixed Connected to the lower end surface of the support column 11, the first positi...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 7 , 8 As shown, the loading device 3 also includes a handle 36, a cover 37 and a positioning bar 38, the positioning bar 38 is slidably engaged with the upper end of the insertion block 33, the cover 37 is fixedly connected to the upper end surface of the positioning bar 38, and the handle 36 is fixed Connected to the middle part of the upper end face of the cover 37.

[0039] When this embodiment is in use, pull the handle 36 fixedly connected in the middle of the upper end surface of the cover 37, place the cover 37 on the upper end surface of the plug-in block 33, and the cover 37 is symmetrically fixed and connected to the positioning strip through the lower end surface of the cover 37 38 is clamped and fixed inside the plug-in block 33, so that the bulk solid waste after alkalization treatment inside the plug-in block 33 is isolated from the outside world, so that the alkalization treatment is repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com