A Boiler Flue Gas Purification Waste Heat Utilization System with Concentration Function

A technology for boiler flue gas and concentration functions, applied in gas treatment, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of low desulfurization and denitrification efficiency, high heat loss of water pollution and flue gas temperature, and achieve good energy saving and emission reduction. Benefit, accelerate desulfurization and denitrification micro-soluble matter precipitation and dust sedimentation, reduce the effect of exhaust heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained without paying creative labor without paying creative labor.

[0022] It is an object of the present invention to provide a boiler flue gas purification heat utilization system having a concentrated function to solve the problem of the above prior art, and achieve the recycling of salt fluid during the purification process.

[0023] In order to make the above objects, features, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

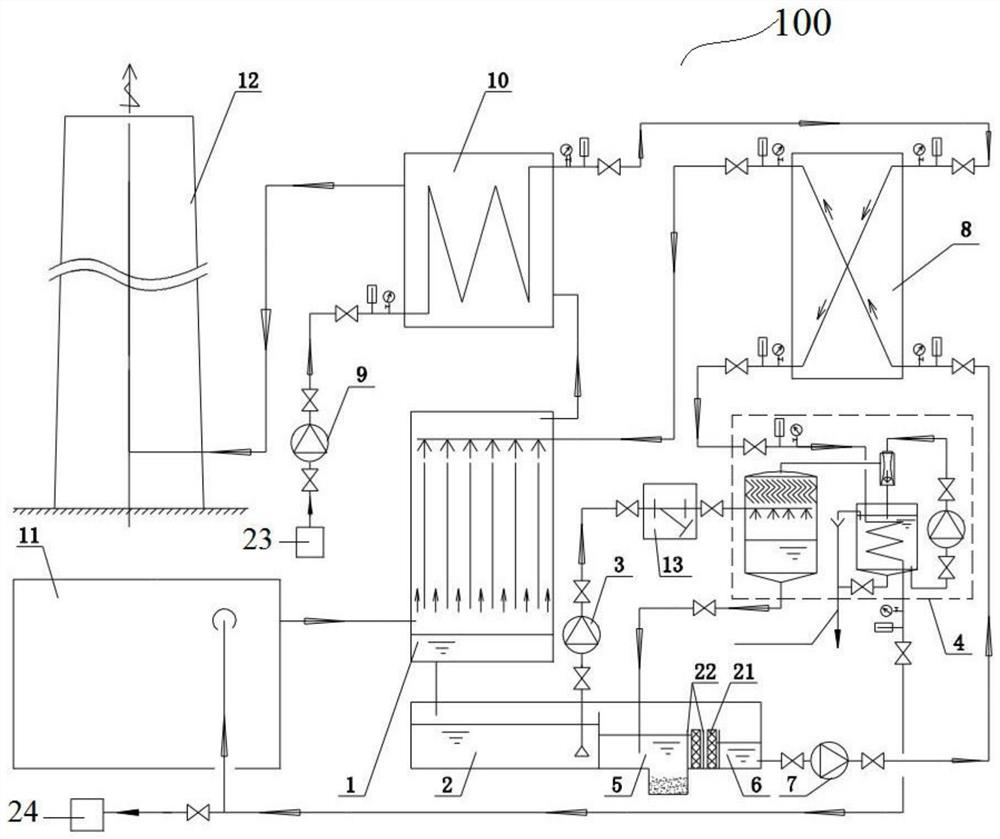

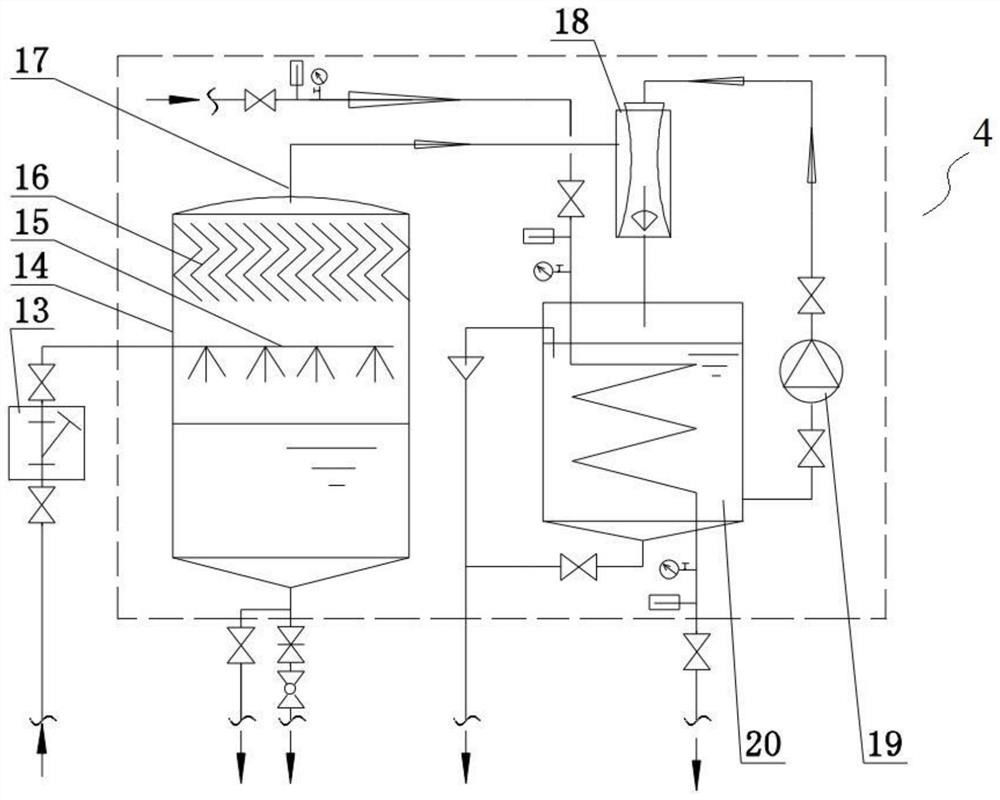

[0024] Such as Figure 1 to 2 As shown: This em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com