Test tube sterilization and disinfection device

A technology of sterilization and disinfection device and test tube, which is applied in the direction of disinfection, water supply device, sanitary equipment for toilets, etc. It can solve the problems of low cleaning efficiency and achieve the effect of avoiding left and right swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

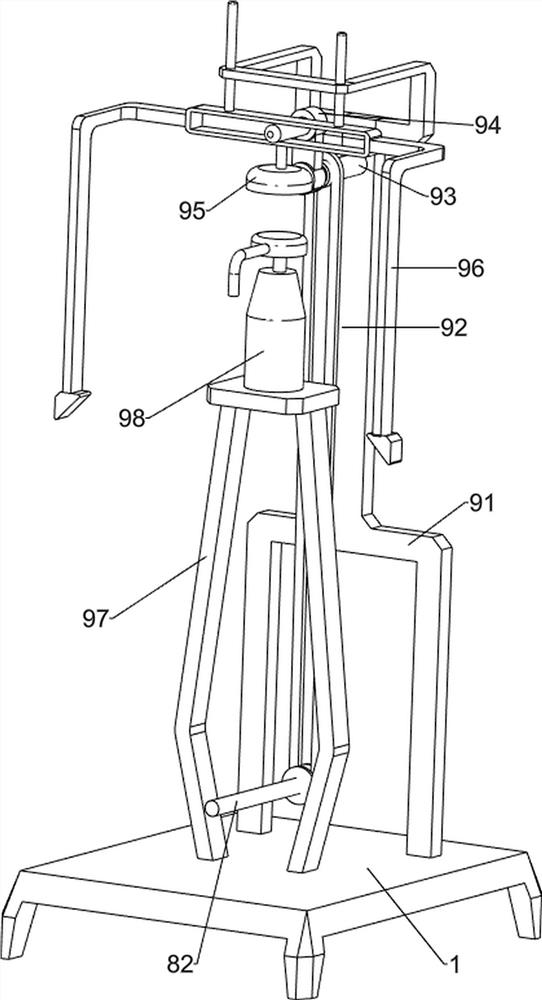

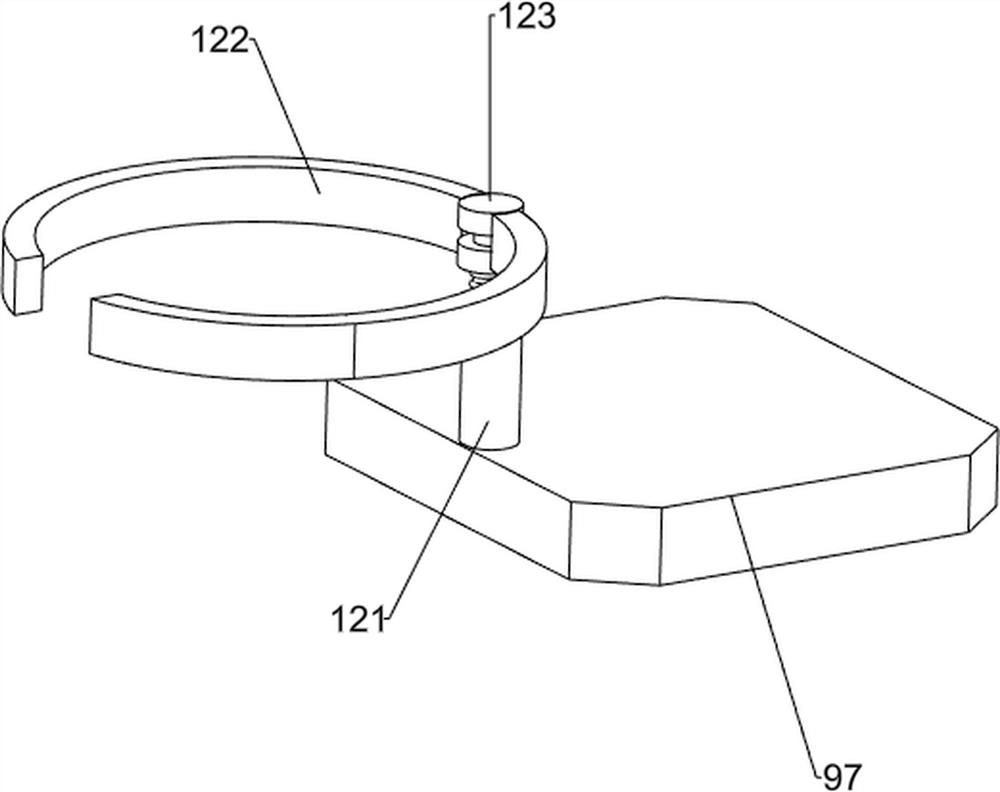

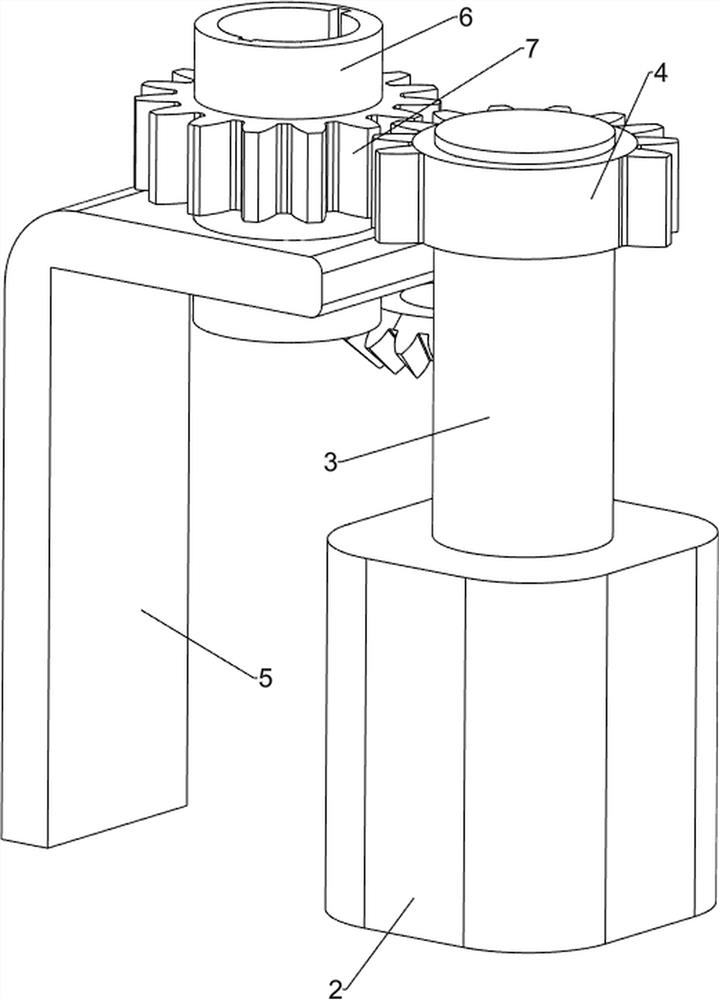

[0056] A test tube sterilization and disinfection device, such as Figure 1-4 As shown, it includes a bottom plate 1, a motor 2, a first rotating shaft 3, a missing gear 4, a first support column 5, a sliding sleeve 6, a first spur gear 7, an oscillation mechanism 8 and a pressing mechanism 9. There is a motor 2, the top of the output shaft of the motor 2 is provided with a first rotating shaft 3, the upper part of the first rotating shaft 3 is provided with a missing gear 4, the left rear side of the top of the bottom plate 1 is provided with a first support column 5, and the upper part of the first support column 5 is connected in a rotational manner There is a sliding sleeve 6, the sliding sleeve 6 is provided with the first straight gear 7, the first straight gear 7 cooperates with the missing gear 4, the base plate 1 is provided with an oscillating mechanism 8, the 8 components of the oscillating mechanism are connected with the sliding sleeve 6, the base plate 1 and the ...

Embodiment 2

[0061] On the basis of Example 1, such as Figure 5-7 As shown, a heating mechanism 10 is also included. The heating mechanism 10 includes a fourth support column 101, a second wedge block 102, a spring 103 and a heating plate 104. The left side of the top of the bottom plate 1 is symmetrically provided with the fourth support column 101. The tops of the four support columns 101 are all slidably connected with a second wedge block 102 , five springs 103 are arranged inside the second wedge block 102 , and a heating plate 104 is arranged between the springs 103 on the same side.

[0062] People put the test tube on the top block 88, start the heating plate 104, and when the first wedge-shaped block 96 moves down to contact with the second wedge-shaped block 102, it drives the second wedge-shaped block 102 to move inwardly, and then drives the heating plate 104 to move toward the inside. The inside moves, and when the heating plate 104 moves to contact with the test tube, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com