Seed Clearing Device for Granary Combine Harvester in Community

A technology for combining community and harvester, which is applied in harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of reduced test reliability and test accuracy, and achieve high-quality cleaning and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

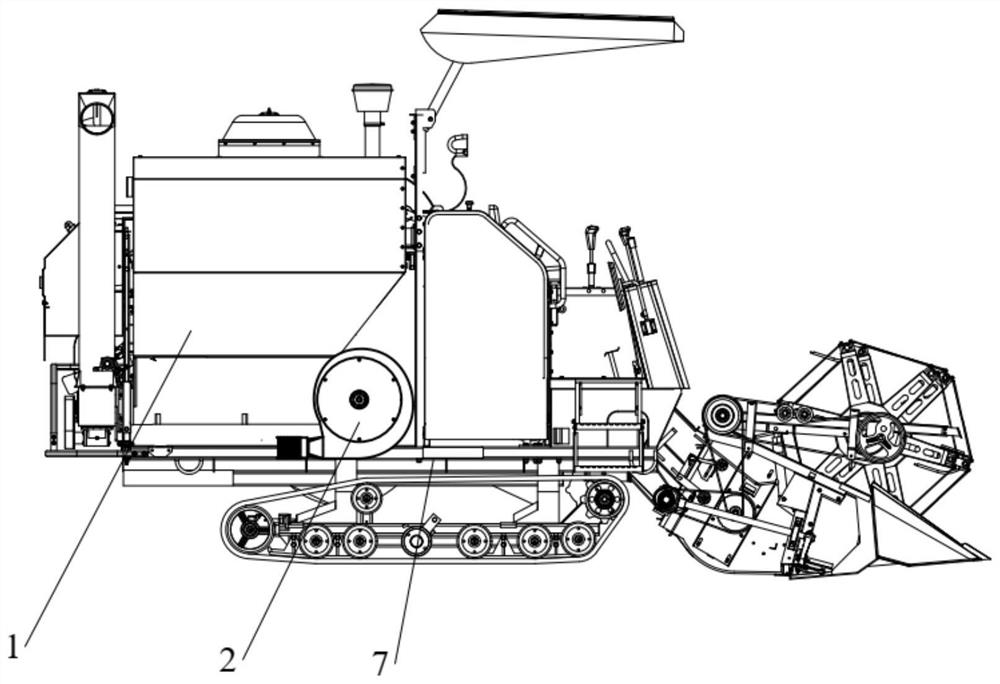

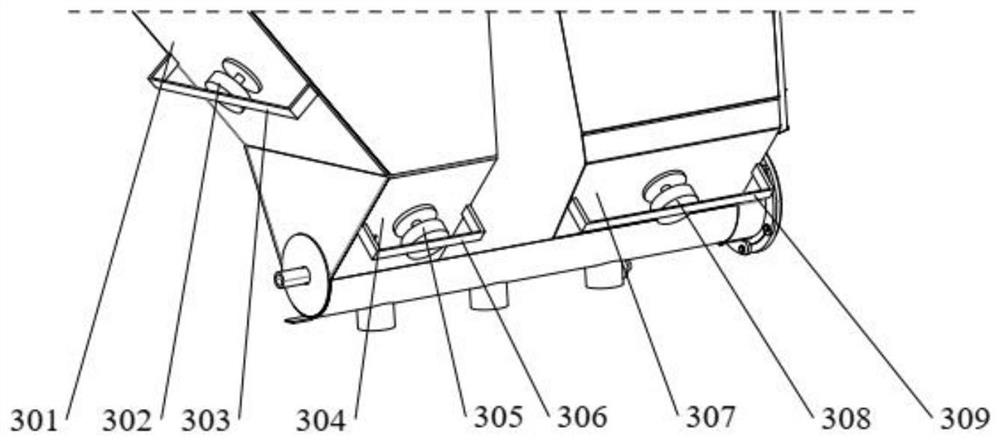

[0024] like Figure 1-8 As shown, a grain clearing device for a grain bin of a plot combine harvester provided by the present invention includes a grain bin 1, an excitation device 3, a grain delivery auger 4, a grain bin bottom plate 5 and a frame 7, and the grain bin 1 is installed on the machine On the frame 7, the granary bottom plate 5 is installed at the bottom of the granary 1, including a bottom plate body 503 and a seed clearing hole 501, the bottom plate body 503 is U-shaped, and the seed clearing hole 501 is opened on the bottom plate body 503 On the bottom surface, the number is at least three, and the vibrating device 3 includes a first side plate 301, a first vibrator 302, a first vibrator bracket 303, a second side plate 304, a second vibrator 305, The second exciter support 306, the third side plate 307, the third exciter 308, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com