Fluidized bed furnace

A technology of fluidized bed furnace and slag, which is applied in the direction of incinerator, fluidized bed combustion equipment, fuel burning in molten state, etc. It can solve the problems of stable combustion of fuel, hindering the flow of fluidized layer, etc., and achieve the purpose of suppressing lumps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

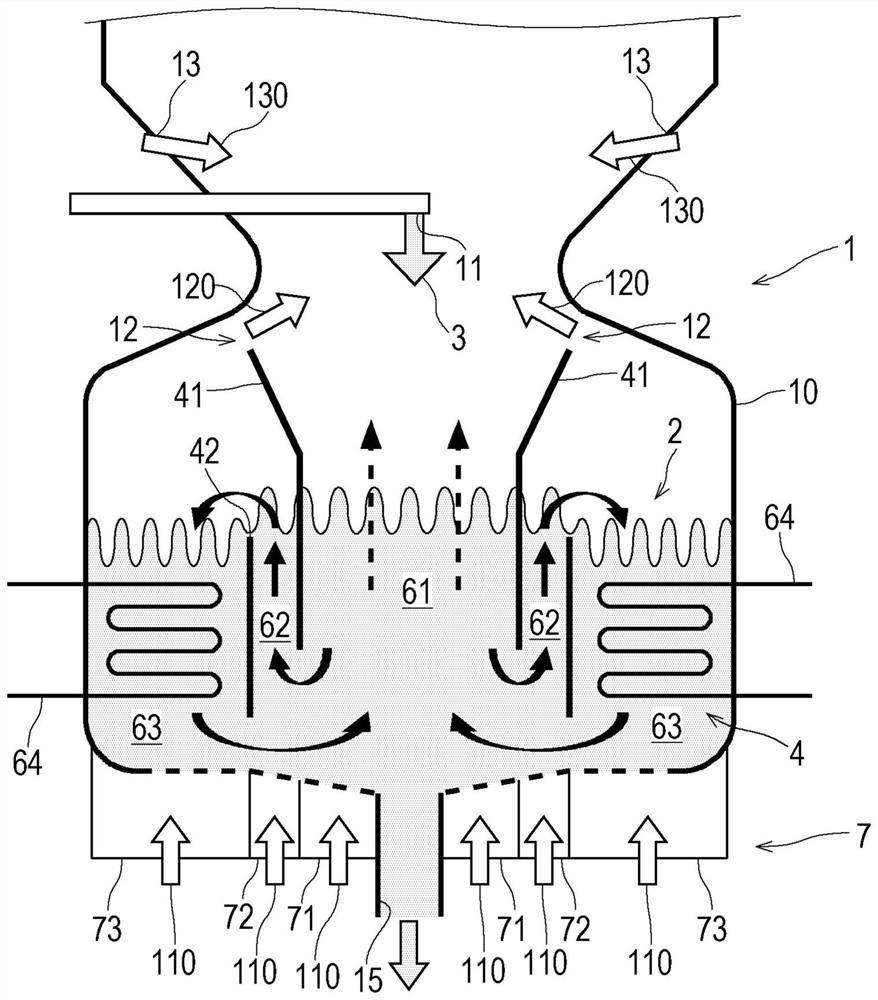

[0025] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic structural diagram of the fluidized-bed furnace 1 which concerns on one Embodiment of this invention. figure 1 The illustrated fluidized bed furnace 1 is an internal circulation fluidized bed type fluidized bed furnace 1 . However, in the present invention, the fluidized bed furnace 1 is not limited. In addition to the internal circulating fluidized bed type, it can also be used in various known forms such as the usual bubbly fluidized bed type, high-speed fluidized bed type, and external circulating fluidized bed type. The invention is applied in a fluidized bed furnace.

[0026] The fluidized bed furnace 1 has a combustion vessel 10 . In the fluidized bed furnace 1, the internal circulation flow layer 2 is formed by the partition walls 41, 42, the flow medium 4 and the fluidization gas supply device 7, wherein the partition walls 41, 42 divide the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com